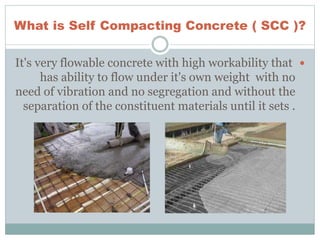

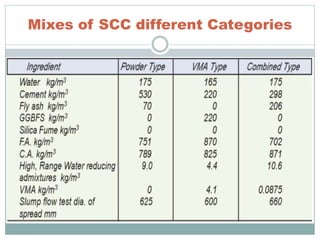

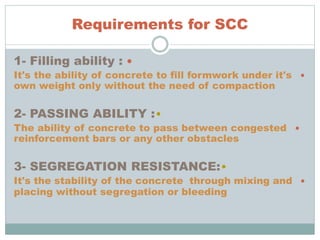

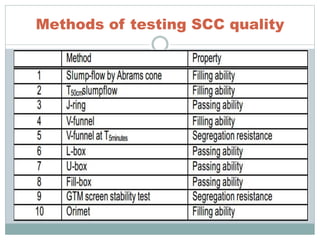

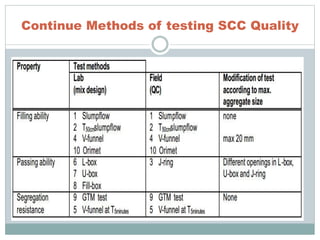

Self-compacting concrete (SCC) is a highly flowable concrete that can spread and consolidate under its own weight without vibration or compaction. Researchers at the University of Tokyo developed SCC in the late 1980s to address labor shortages. By the early 1990s, Japan was using SCC without vibration, and its use spread to other countries. SCC offers benefits like reduced labor costs, faster construction, and improved safety and finishes. It requires special mix designs using superplasticizers, viscosity agents, and mineral admixtures to achieve flowability, passing ability through reinforcement, and resistance to segregation.