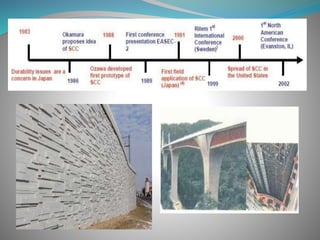

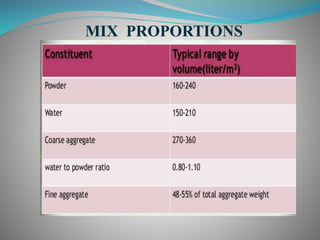

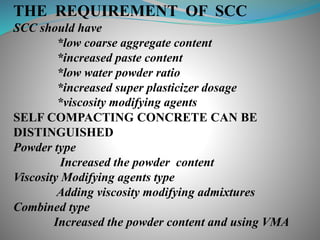

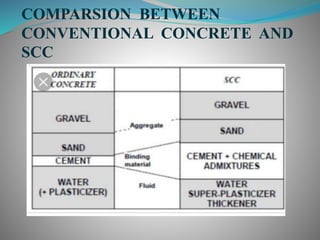

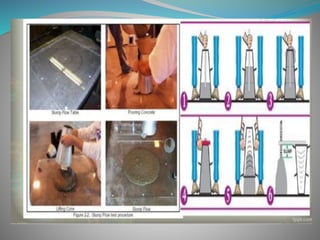

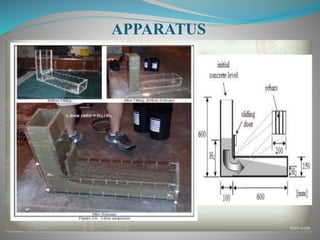

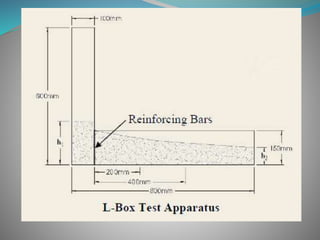

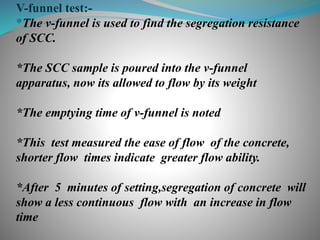

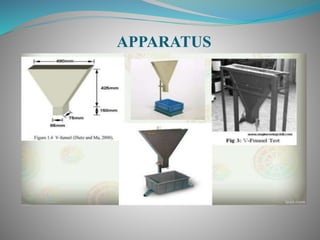

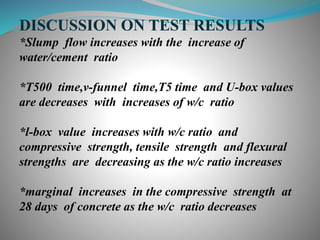

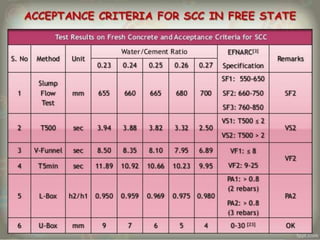

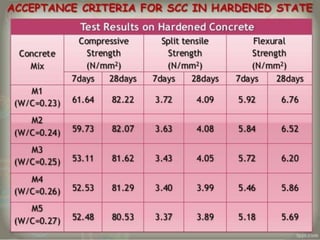

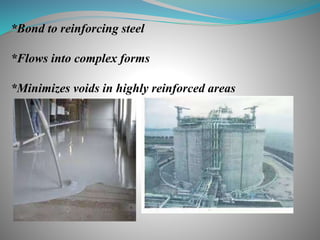

Self-compacting concrete (SCC) was developed in Japan in the 1980s to achieve complete compaction without vibration. SCC flows under its own weight, fills formwork and passes through reinforced areas without segregation of ingredients. It consists of cement, fine and coarse aggregates, chemical and mineral admixtures. Superplasticizers and viscosity modifying agents provide workability and stability. Tests like slump flow, V-funnel, and J-ring evaluate filling ability, passing ability and resistance to segregation. SCC offers benefits of reduced labor, better compaction and surface finish compared to conventional concrete but requires more precise material proportions and quality control.