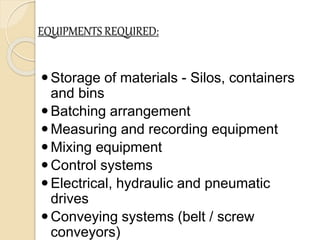

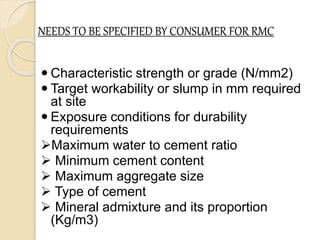

This presentation discusses the mix design procedure for ready mix concrete. It begins with an introduction to ready mix concrete, including its history. It then discusses the materials used - aggregates, cement, admixtures and fly ash. The equipment, mixing processes, specifications from customers, and quality checks are also outlined. Finally, the benefits of ready mix concrete are noted as consistent quality, strength, and reduced human error due to mechanization.