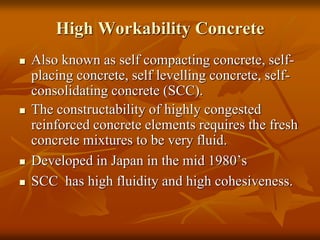

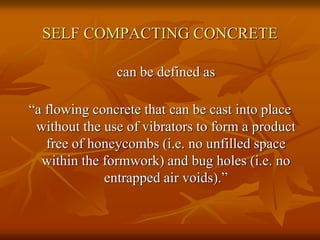

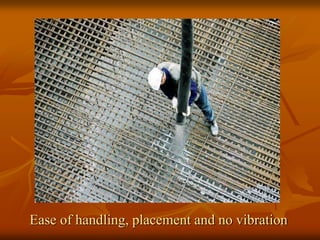

High workability concrete, also known as self-compacting concrete, has properties that allow it to flow and fill congested areas without vibration. It contains a higher amount of cementitious material, less coarse aggregate, more fine aggregate, and admixtures like superplasticizers and viscosity modifying agents. Tests like the slump flow and J-ring tests evaluate its flowability and passing ability. Benefits include faster construction, easier placement, and smoother surfaces, while drawbacks include potentially higher cost and drying/thermal shrinkage.