Embed presentation

Download as PDF, PPTX

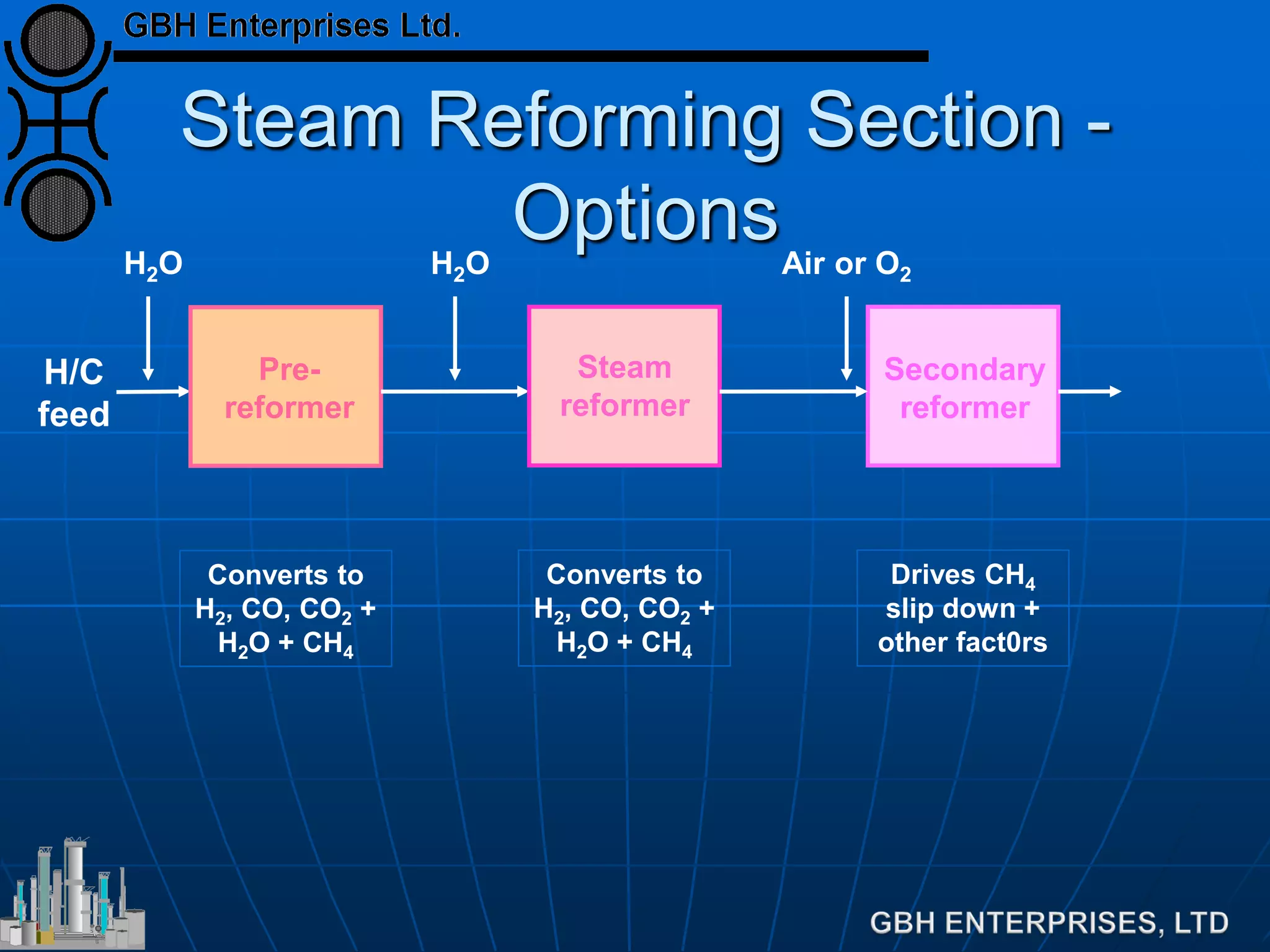

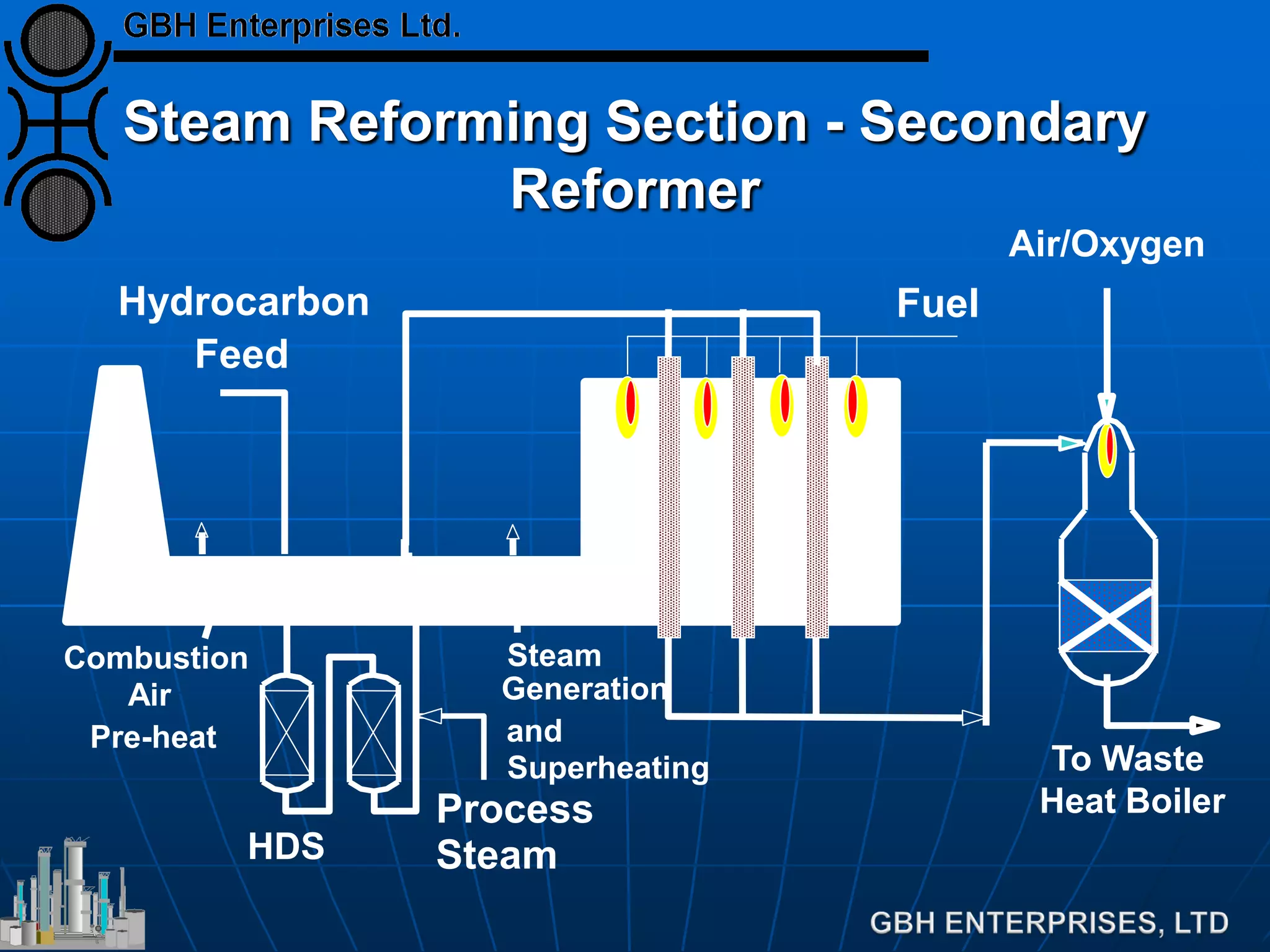

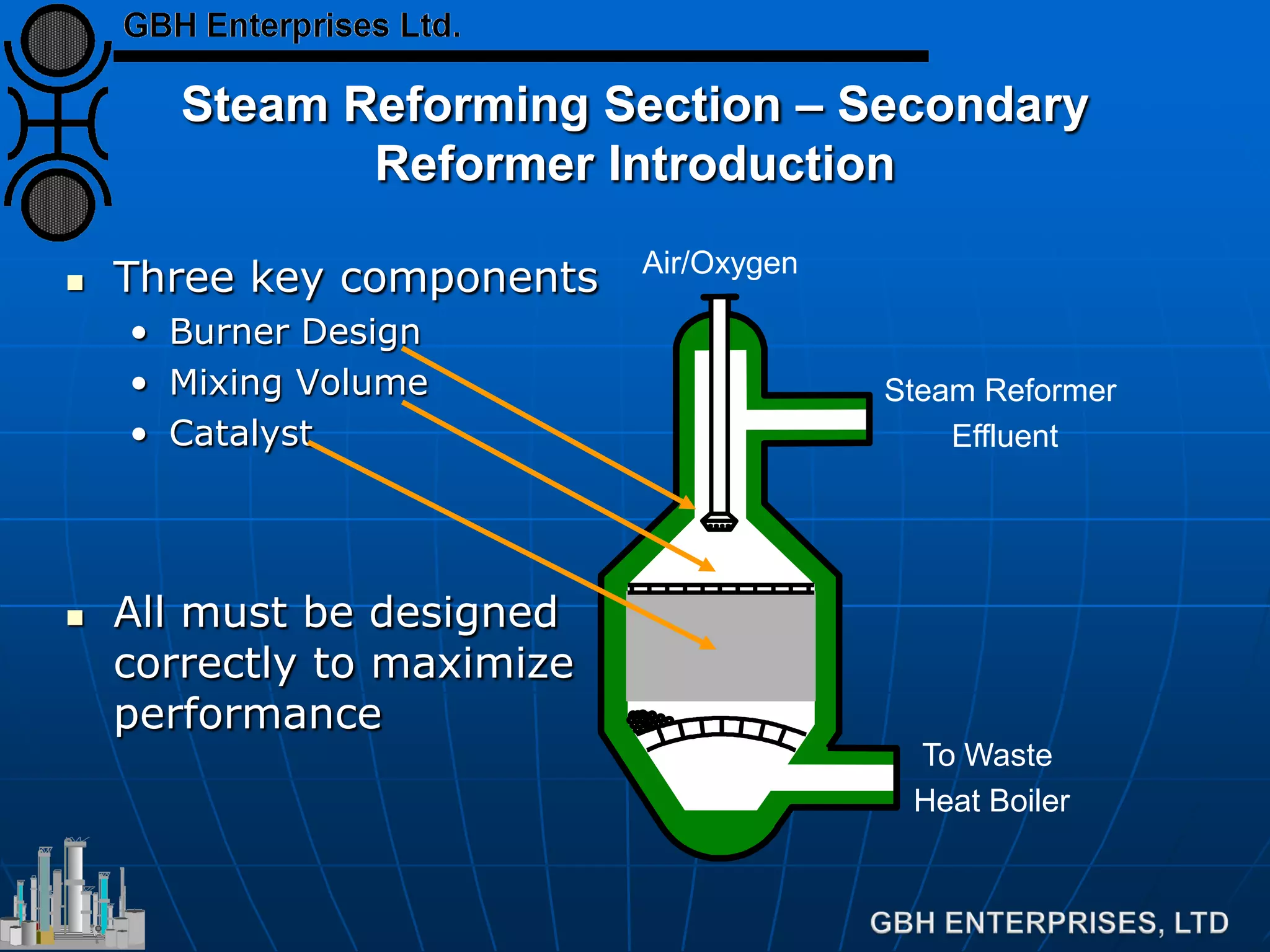

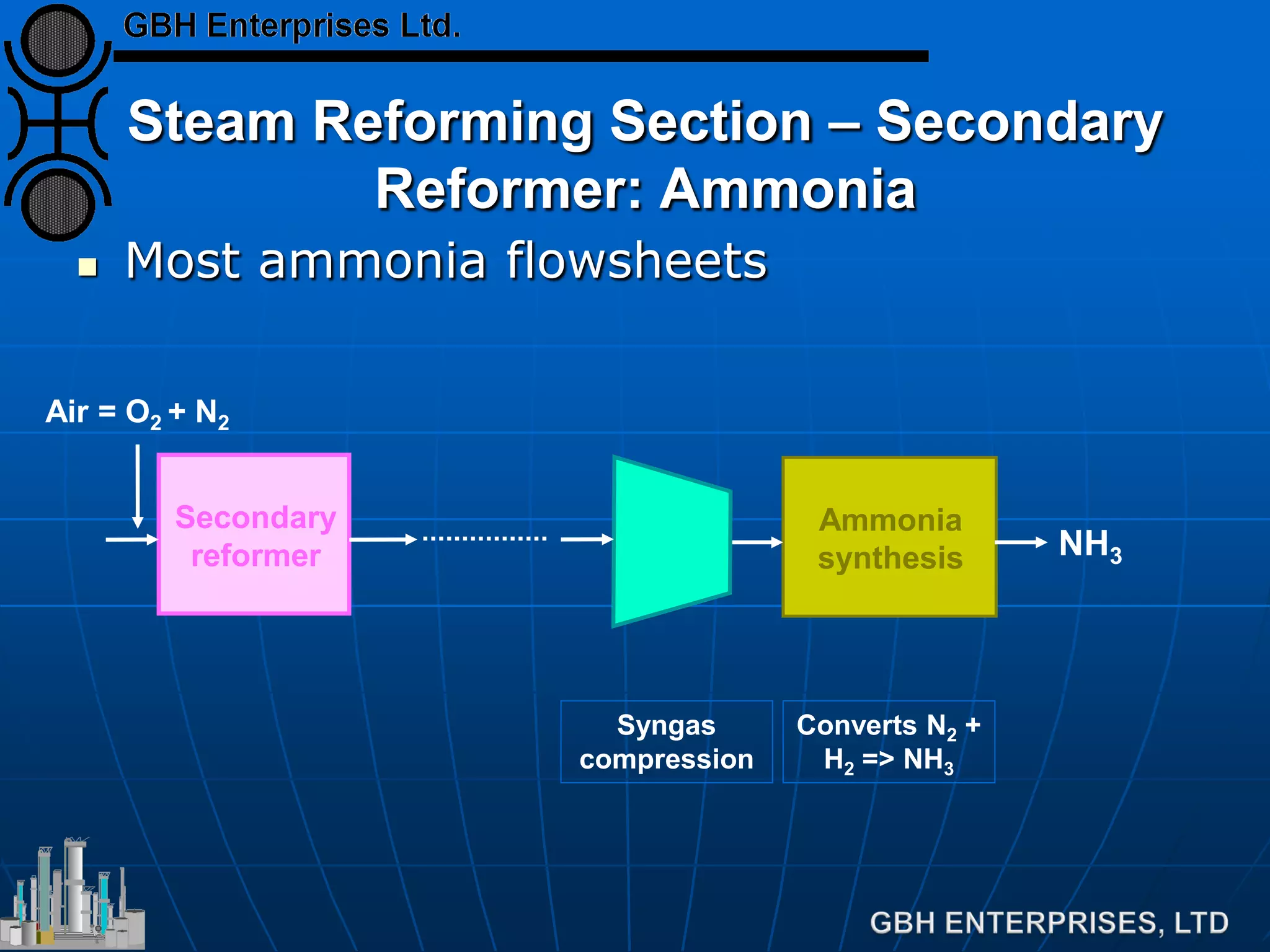

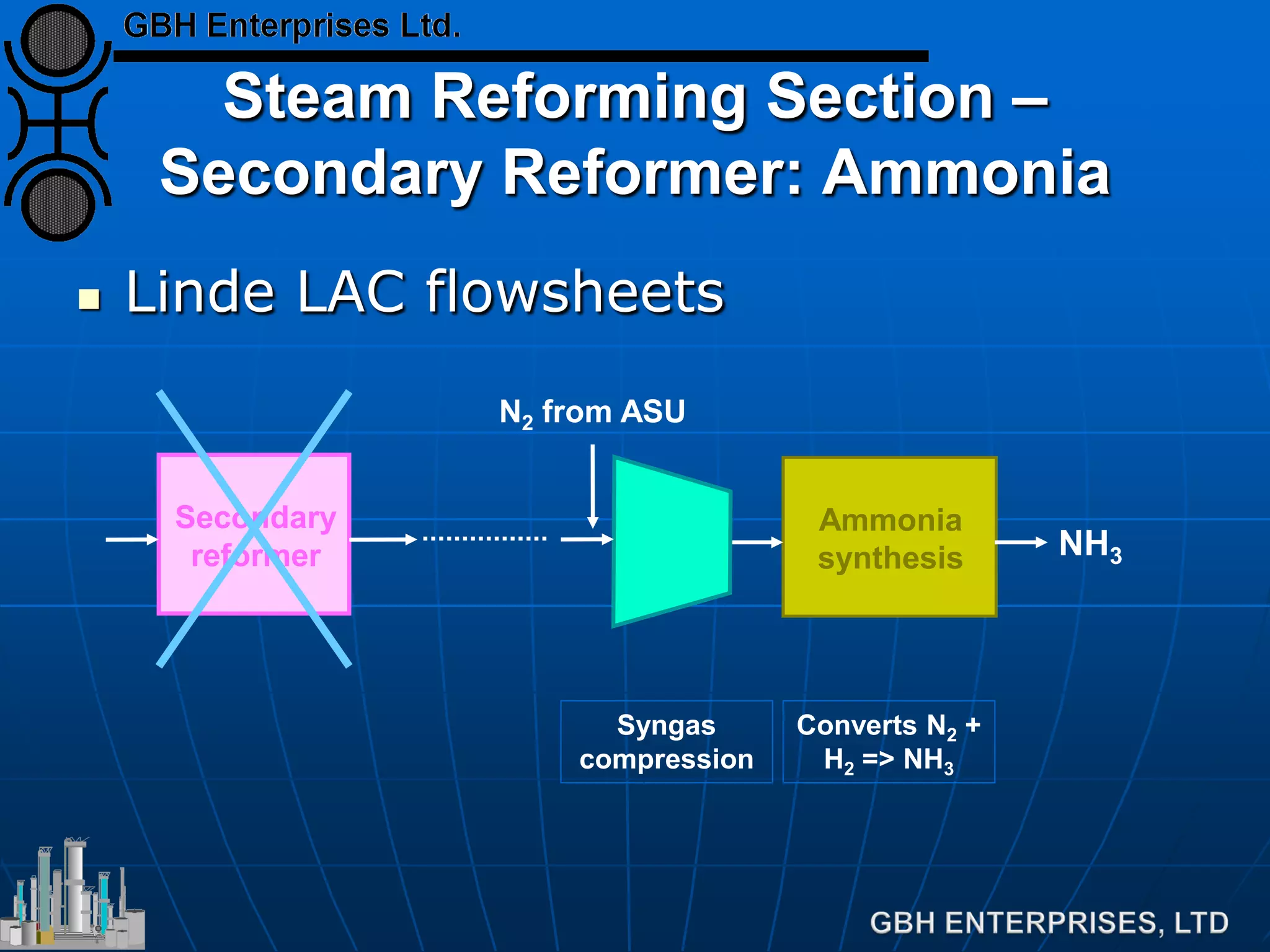

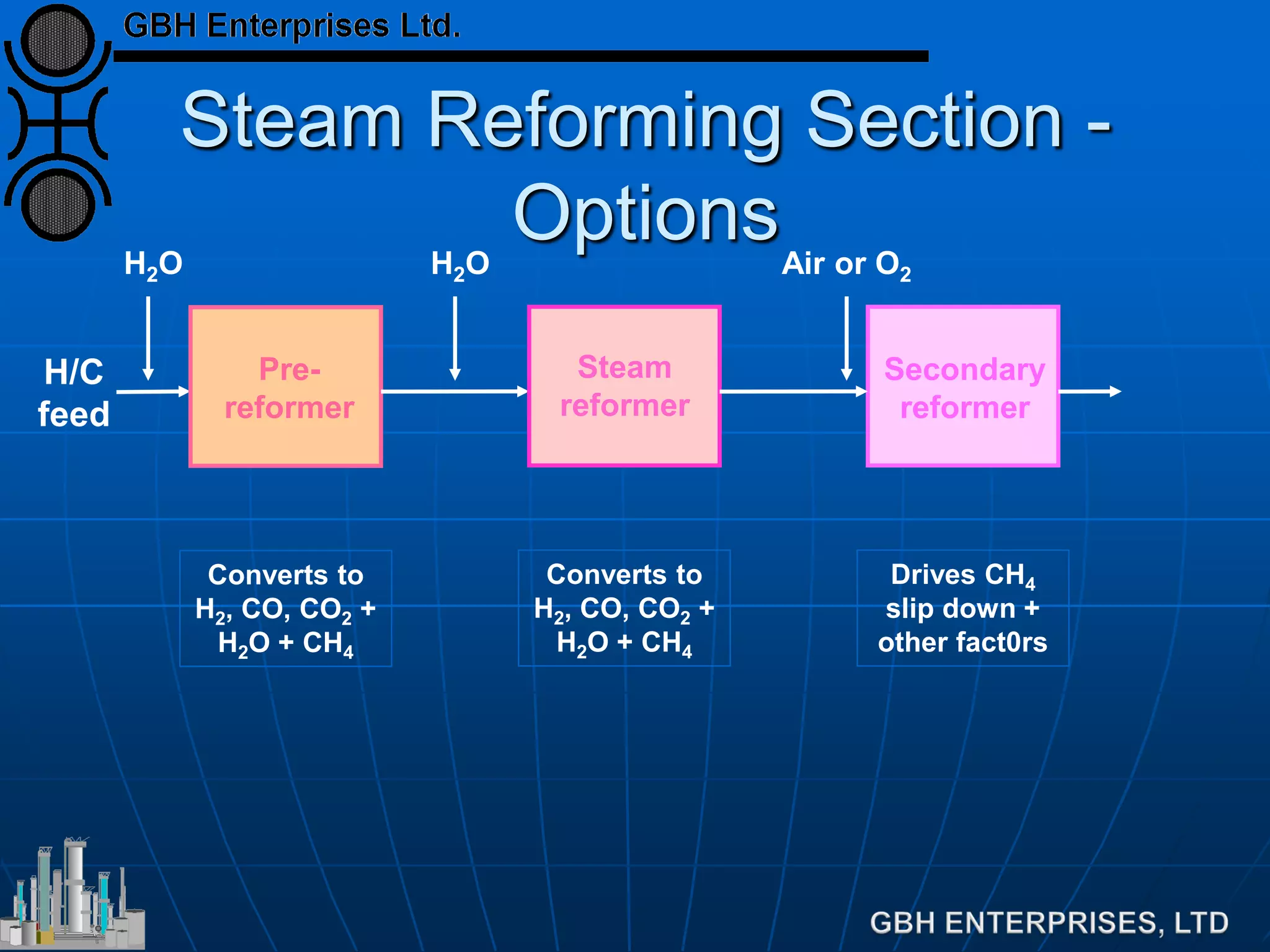

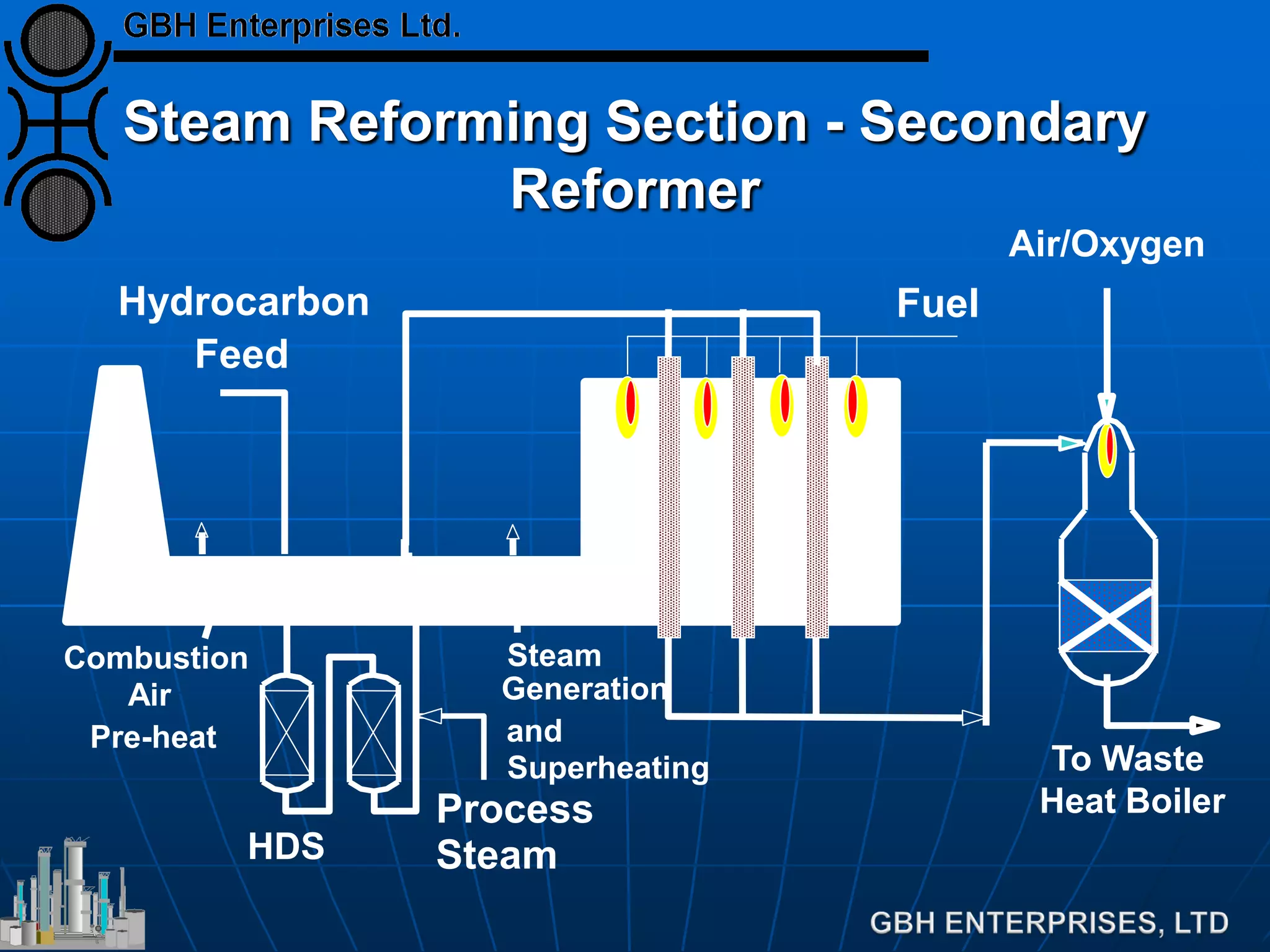

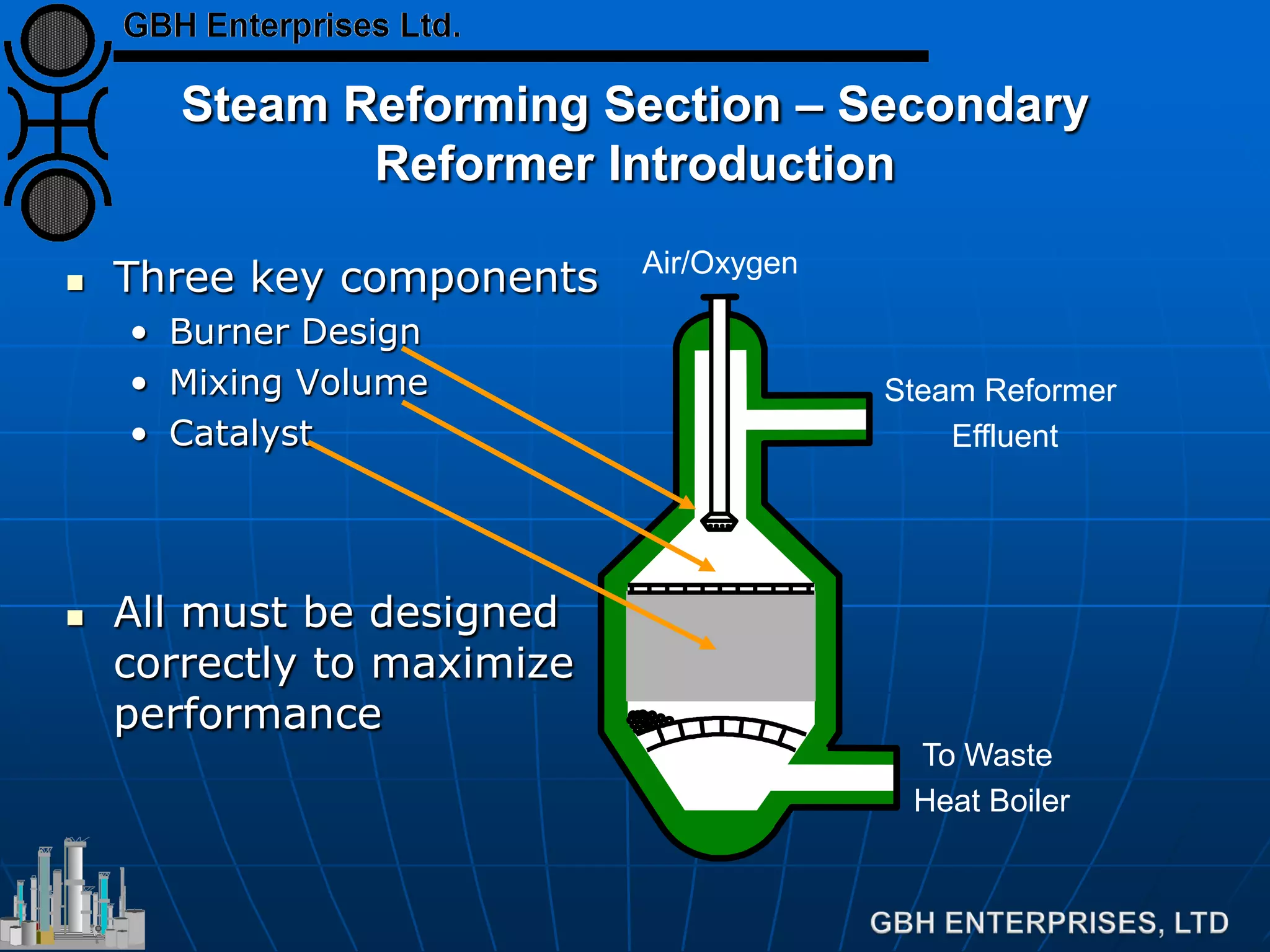

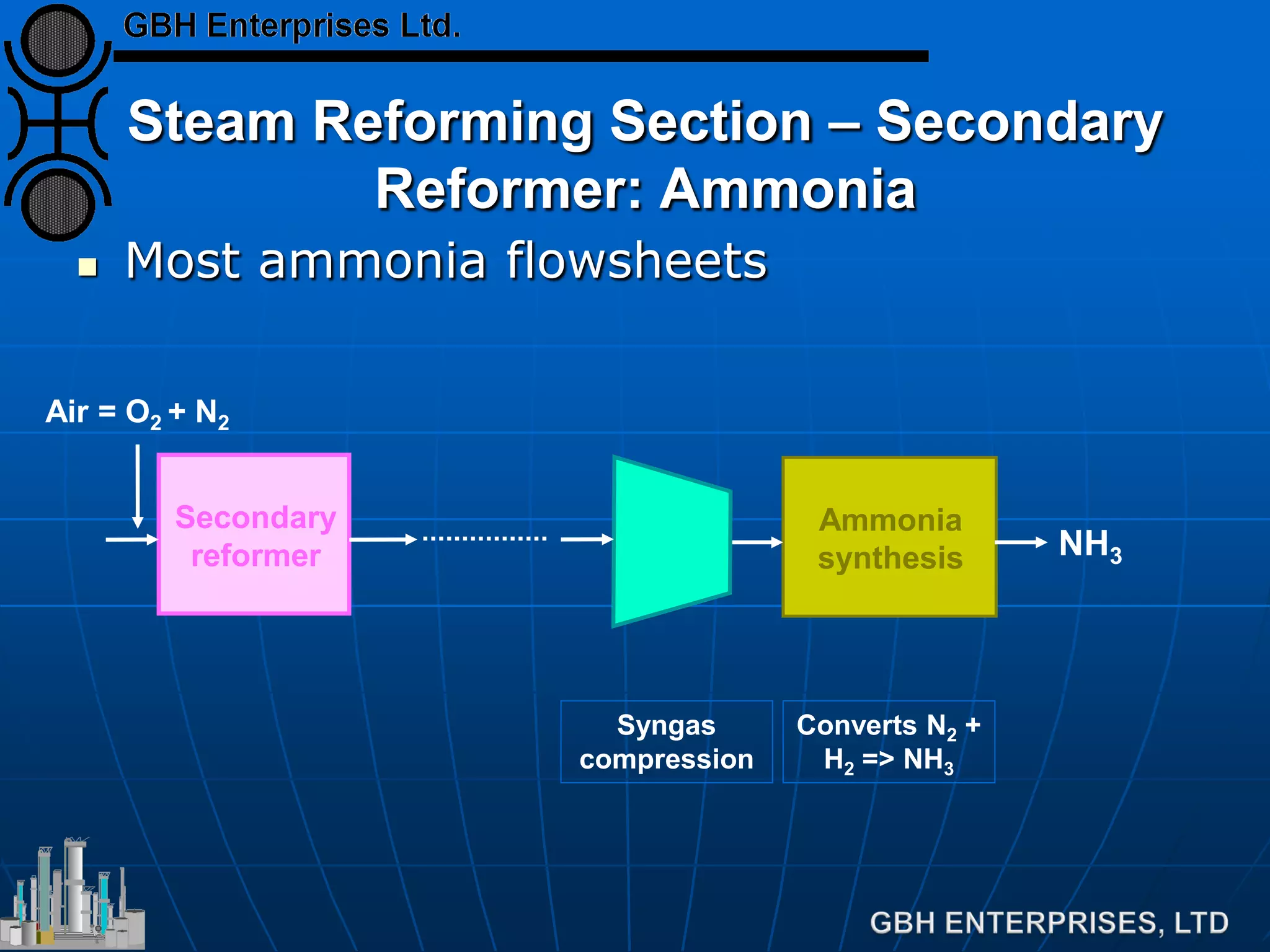

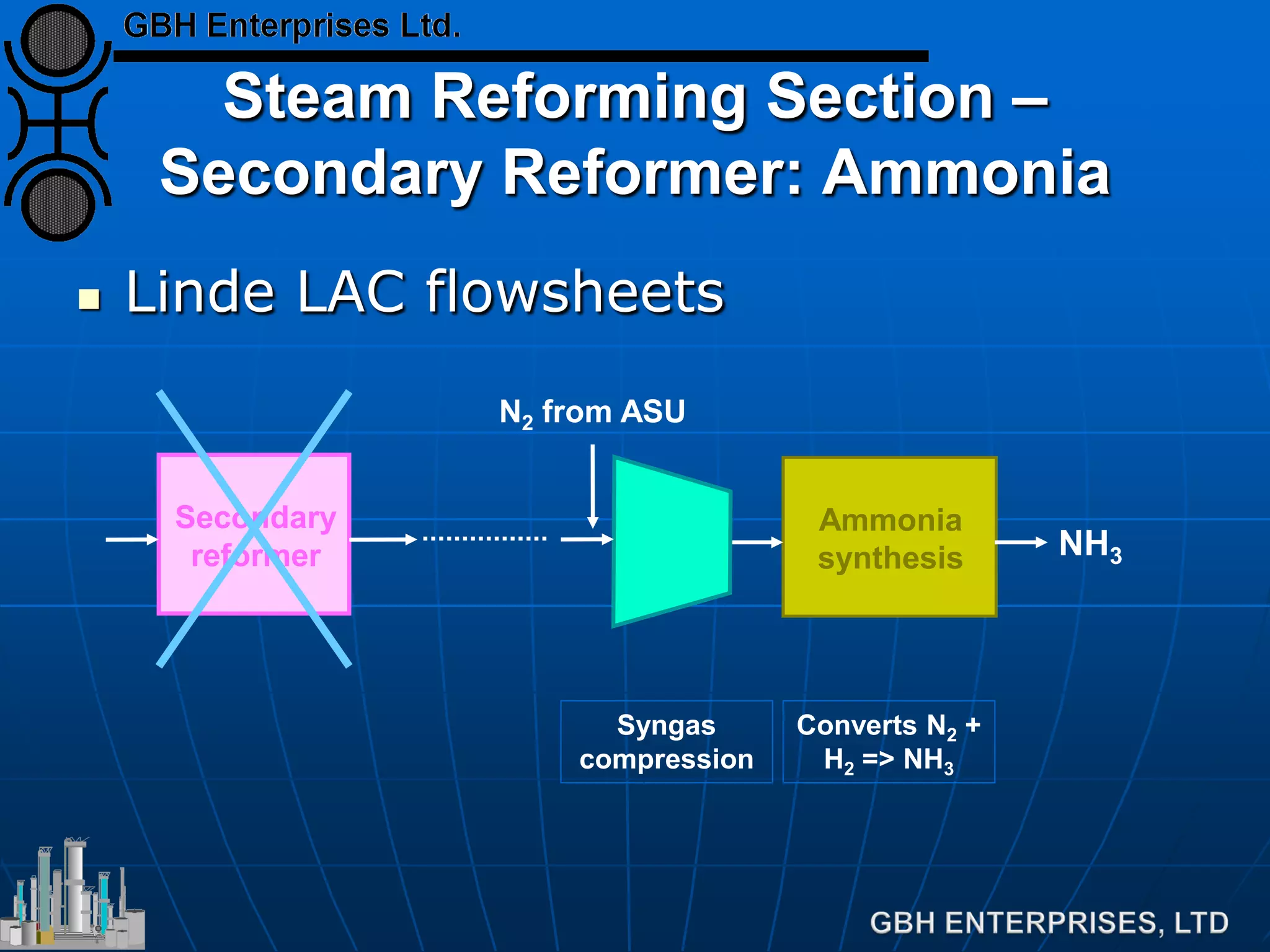

This document discusses secondary reforming in ammonia and hydrogen/syngas production. It explains that ammonia plants commonly use a secondary reformer fired with air, as the nitrogen from air is useful for ammonia synthesis. However, hydrogen/syngas plants less commonly use secondary reforming because nitrogen cannot be tolerated in the process and an air separation unit may not be available or affordable to provide oxygen. The document outlines the key components of secondary reformers - the burner design, mixing volume, and catalyst - which must all be optimized to improve performance.