Single-cell proteins (SCP) are derived from edible unicellular microorganisms and serve as ingredients or substitutes for protein-rich foods, suitable for both human and animal feeds. The production process utilizes agricultural waste for microbial growth, while various techniques enhance concentration and dewatering, albeit at high costs. SCP offers advantages such as high protein content and rapid growth rates, making it a promising solution for future food production as global population demands rise.

![INTRODUCTION

Single-cell proteins (SCP) refers to edible unicellular microorganisms.

The biomass or protein extract from pure or mixed cultures of algae, yeasts,

fungi or bacteria

It is used as an ingredient or a substitute for protein-rich foods.

It is suitable for human & animal feeds.

Agricultural waste are used as starter/media for microbial growth.

Max Delbrück and his colleagues found out the high value of surplus

brewer’s yeast as a feeding supplement for animals

[SOURCE – VECTORSTOCK]](https://image.slidesharecdn.com/singlecellprotein-200208184913/85/Single-cell-protein-2-320.jpg)

![INDUSTRIAL PRODUCTION TECHNIQUES

[SOURCE – RESEARCH GATE]](https://image.slidesharecdn.com/singlecellprotein-200208184913/85/Single-cell-protein-5-320.jpg)

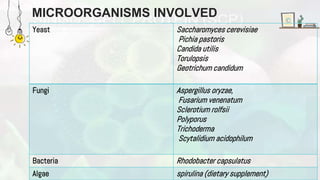

![DIFFERENT PROCESSING TECHNIQUE

PRUTEEN PROCESS AND SYMBA PROCESS

[SOURCE – INDUSTRIALBIOTECHNOLOGY] [SOURCE – INDUSTRIALBIOTECHNOLOGY]](https://image.slidesharecdn.com/singlecellprotein-200208184913/85/Single-cell-protein-6-320.jpg)