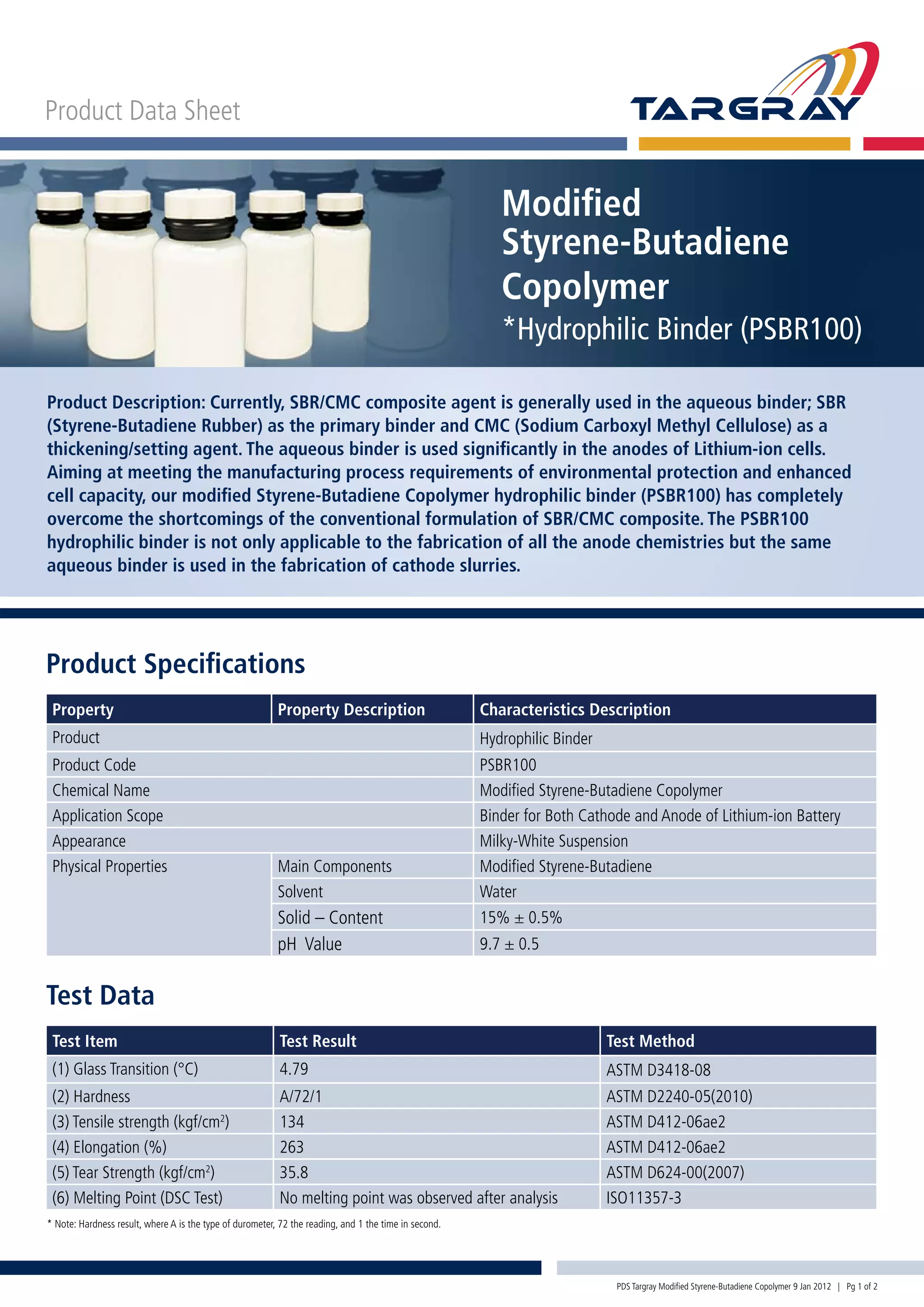

The document describes the modified styrene-butadiene copolymer hydrophilic binder (psbr100), which is designed for use in lithium-ion batteries as both anode and cathode binders, overcoming limitations of traditional sbr/cmc formulations. Key advantages include environmental friendliness due to water-based solvent, reduced amounts required in slurry, and improved electrode performance. Test results indicate that the psbr100 effectively enhances cell capacity and production efficiency without compromising electrochemical properties compared to conventional binders.