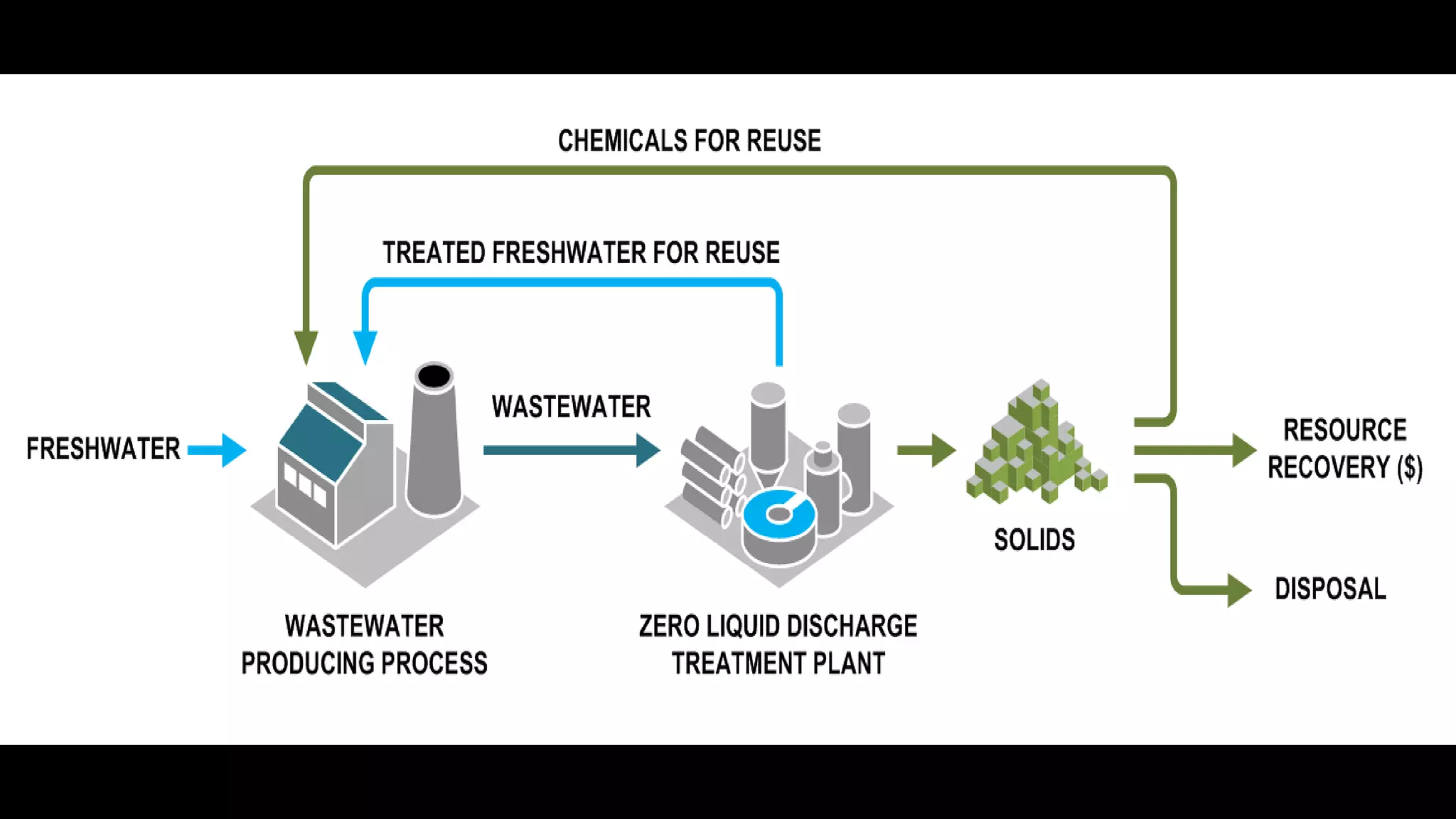

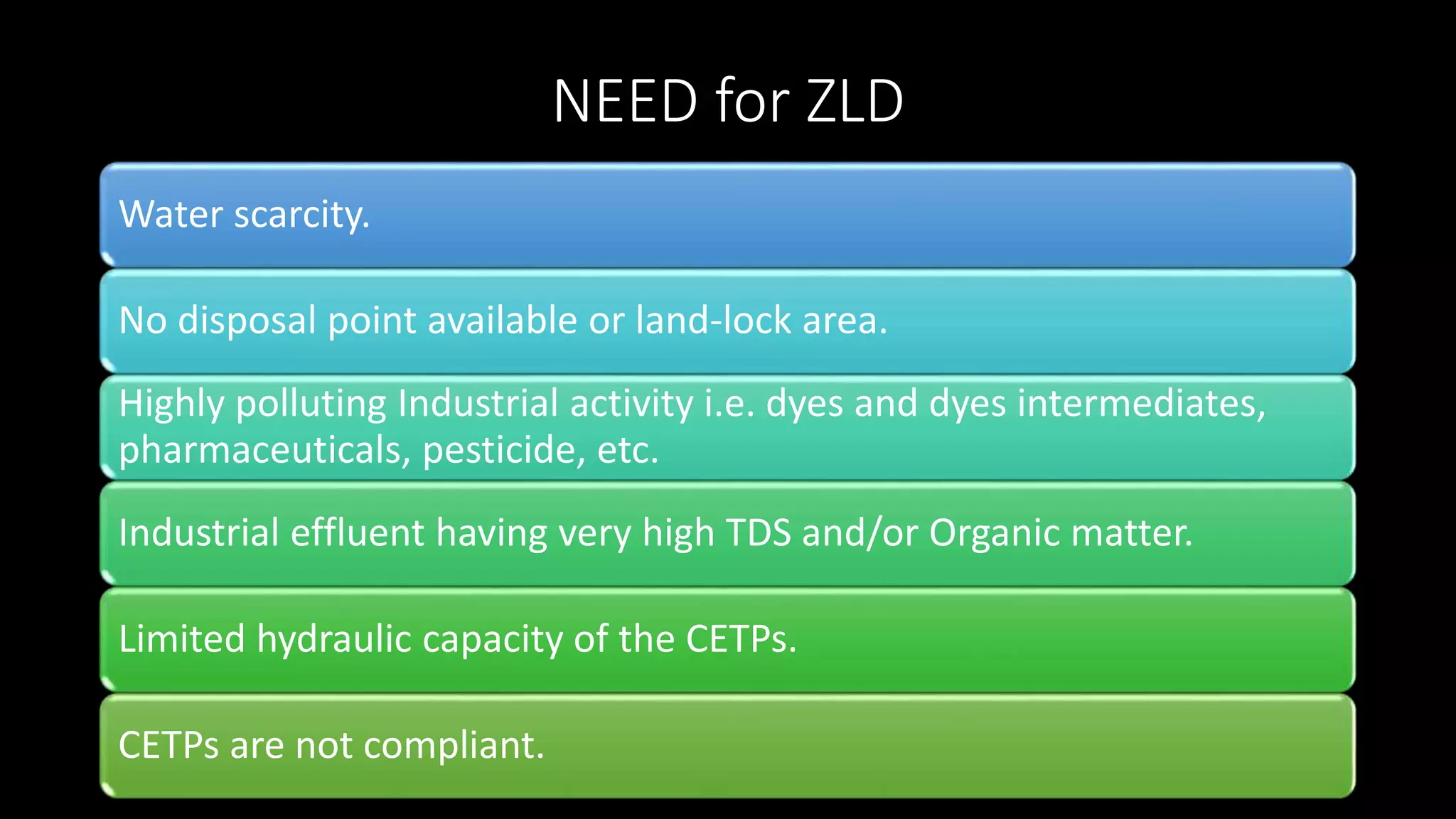

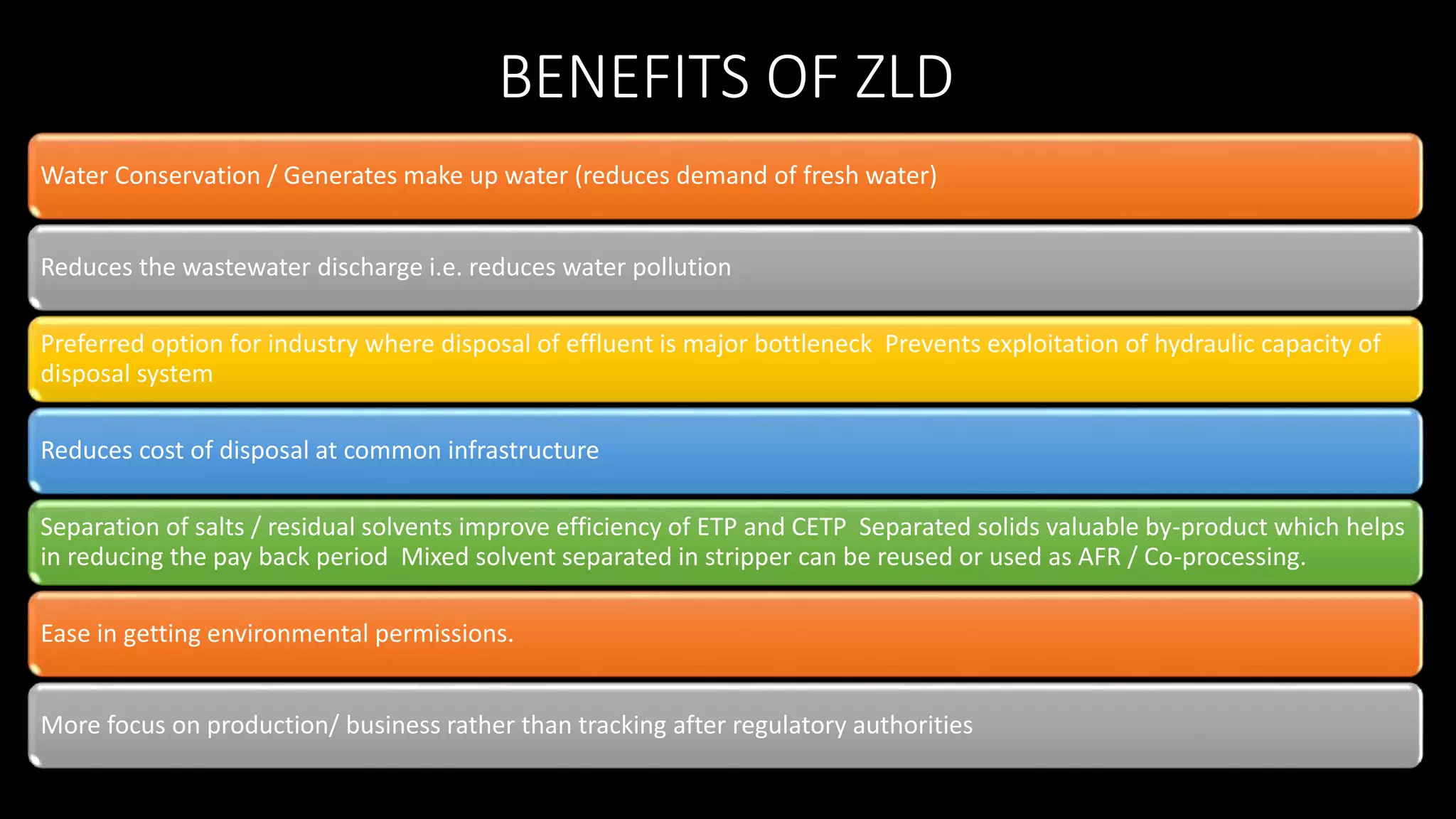

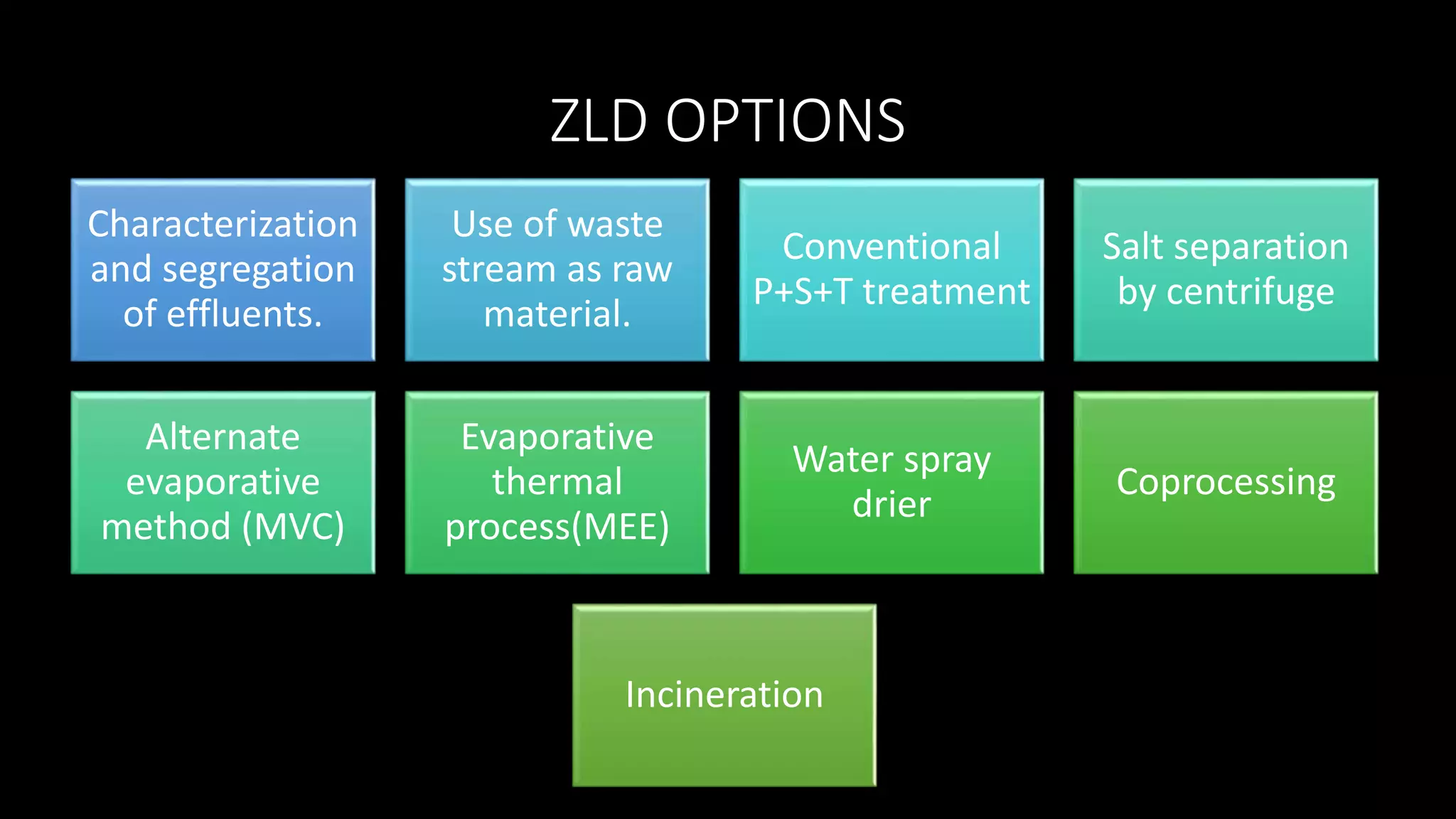

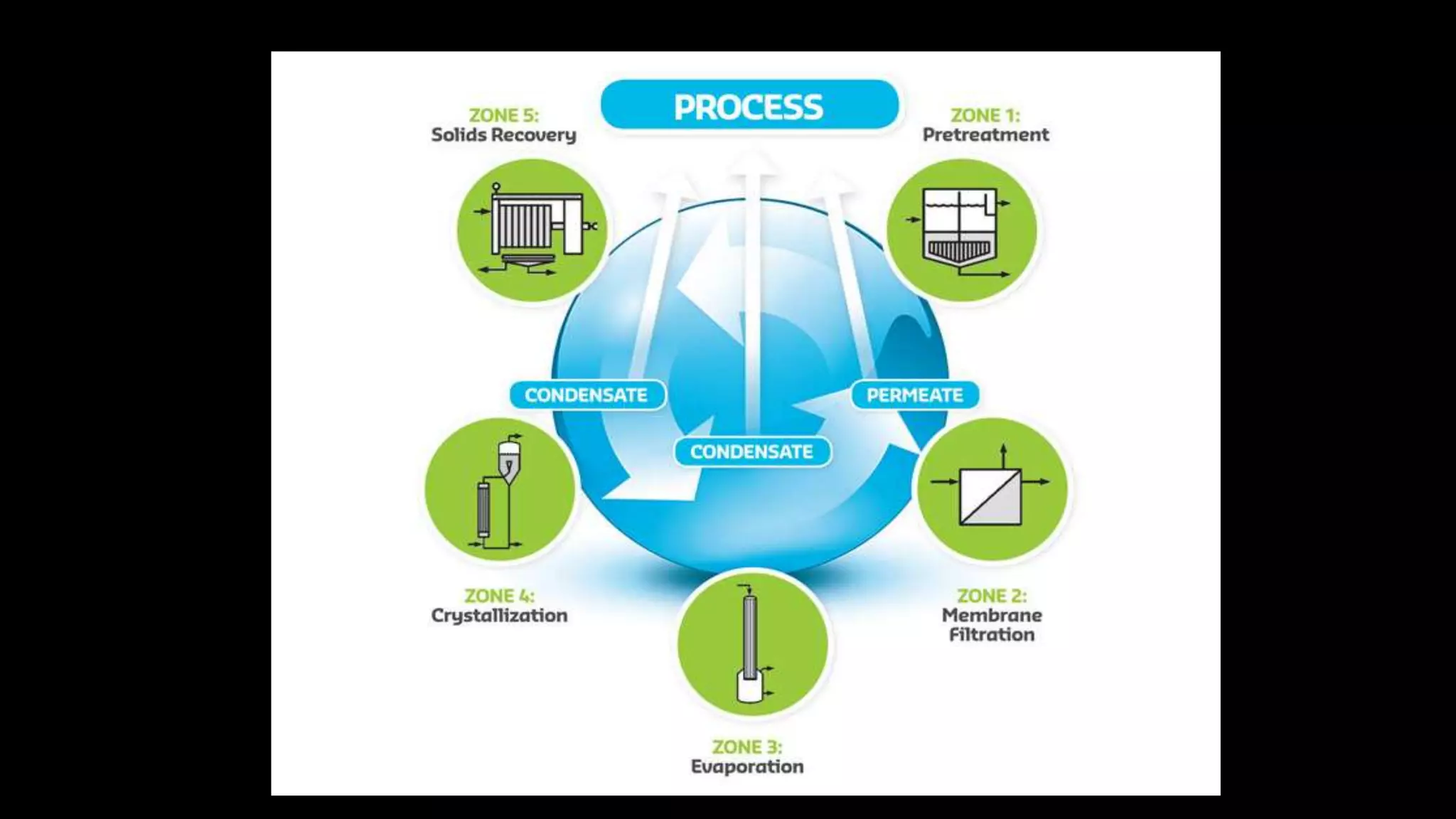

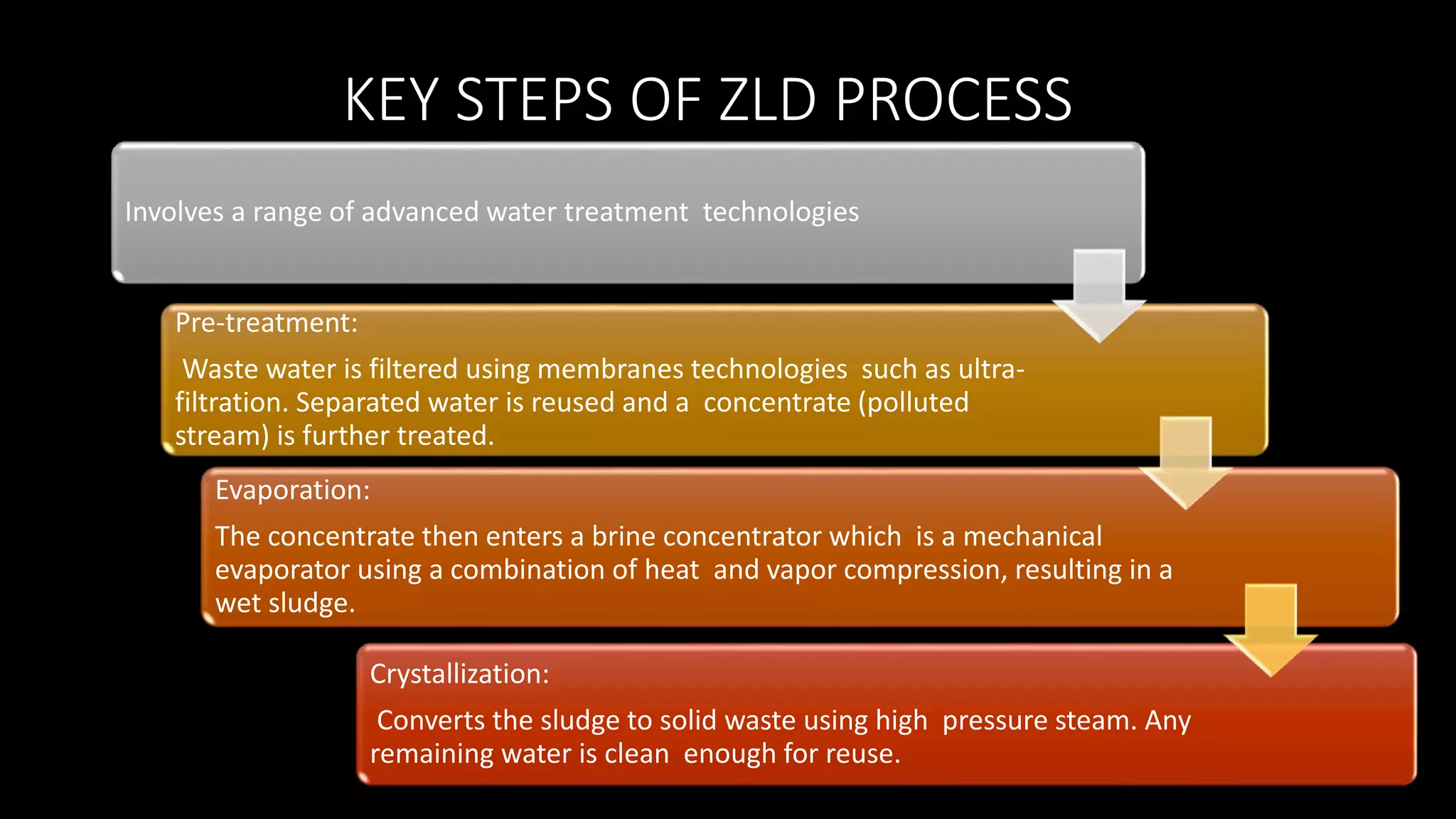

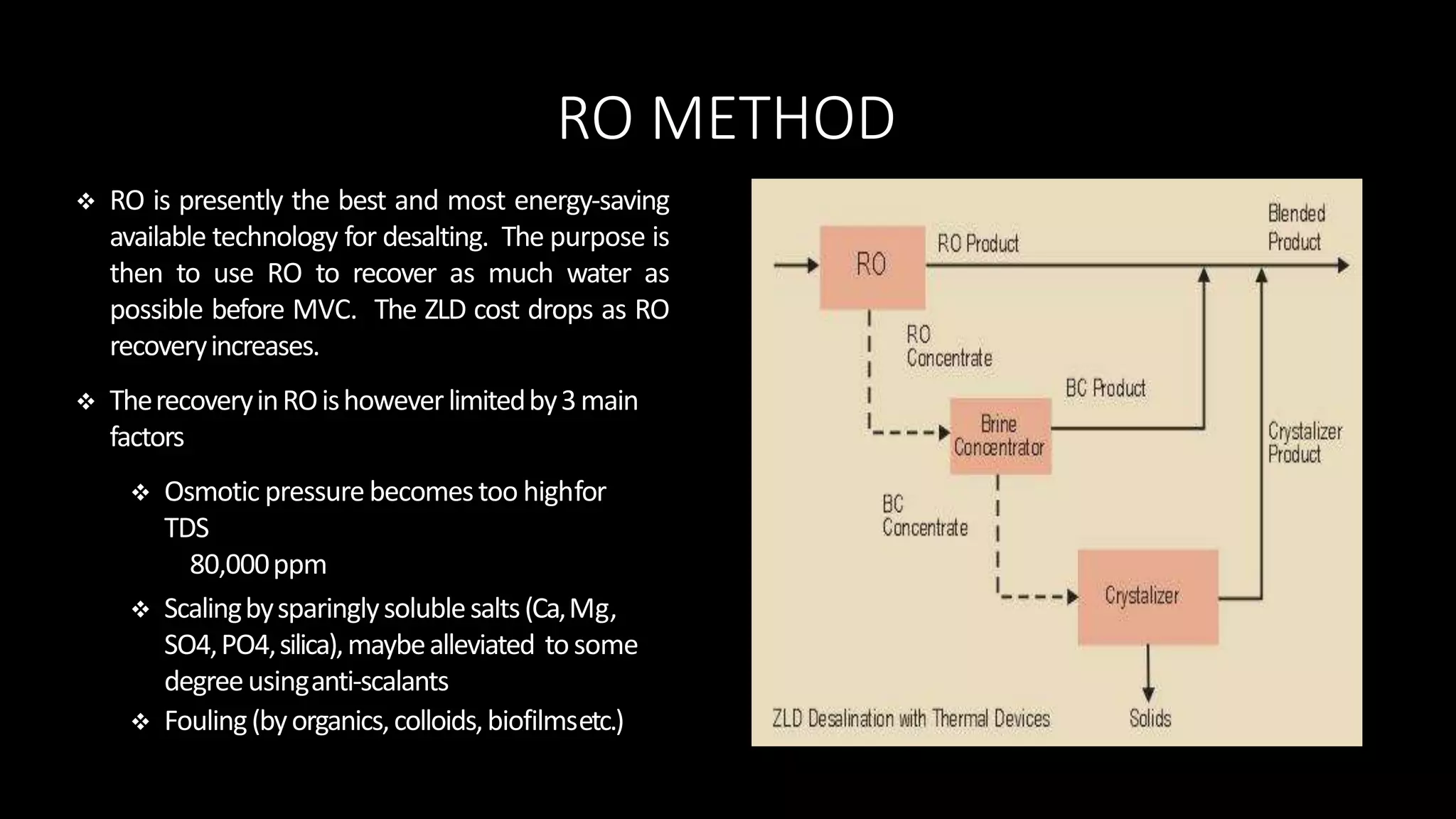

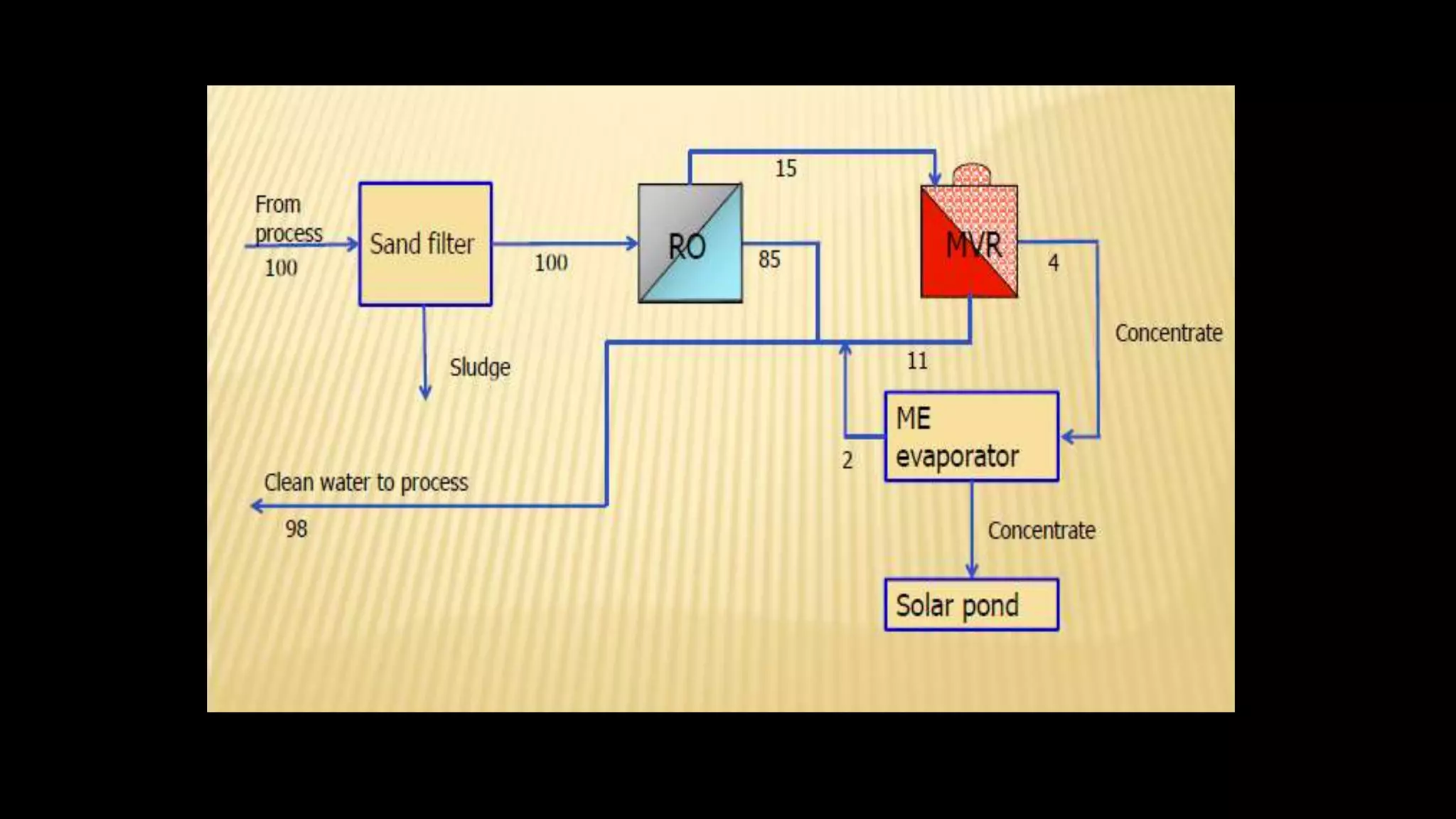

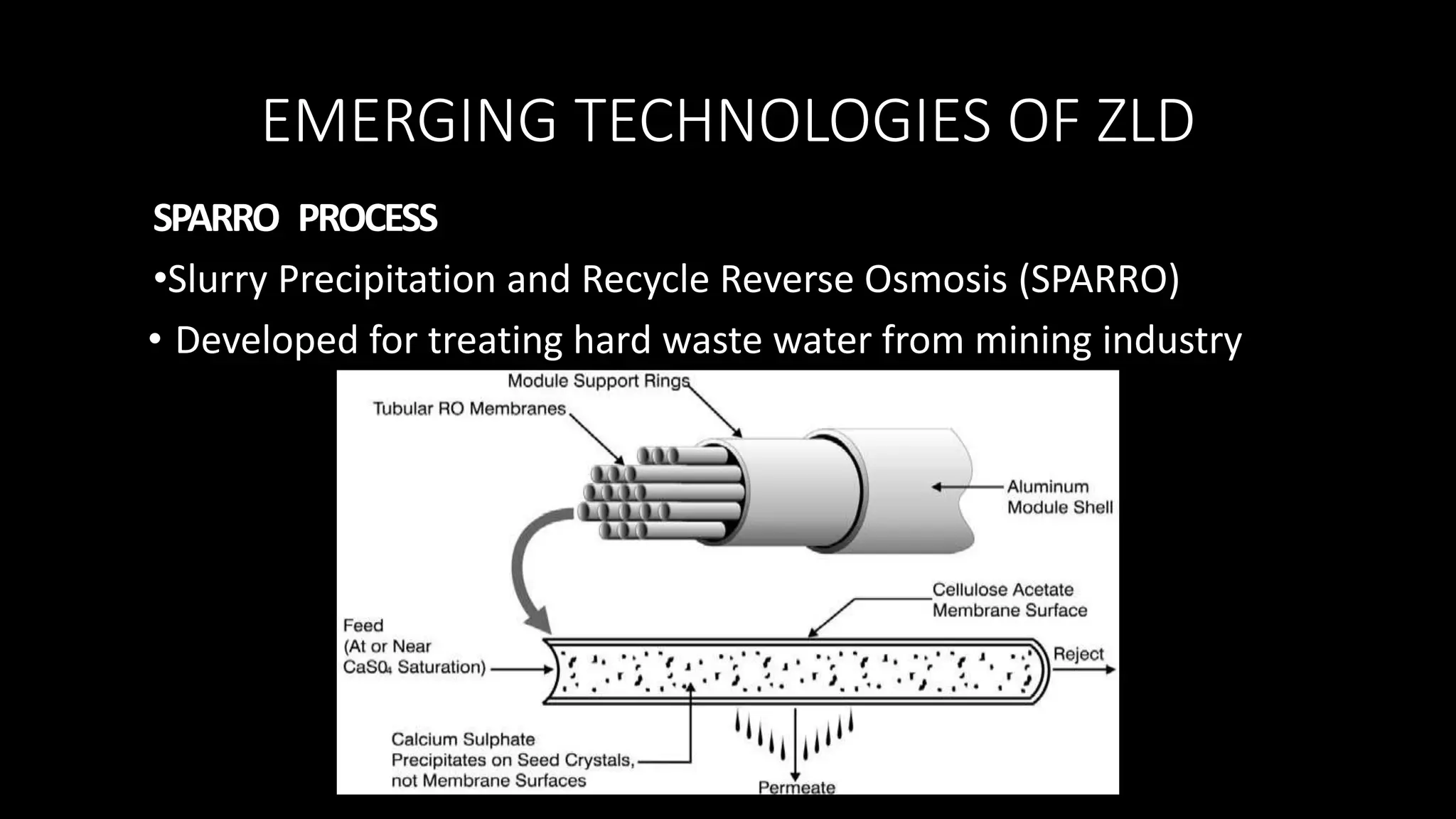

This document discusses zero liquid discharge (ZLD) systems. It provides background on the need for ZLD due to water scarcity issues. It then describes the key steps in a ZLD process, which involves pre-treatment, evaporation, and crystallization to separate water for reuse from solids for disposal. Common technologies used are reverse osmosis, mechanical vapor recompression, and multiple effect evaporators. The document concludes with two case studies of industries that have implemented ZLD systems successfully.