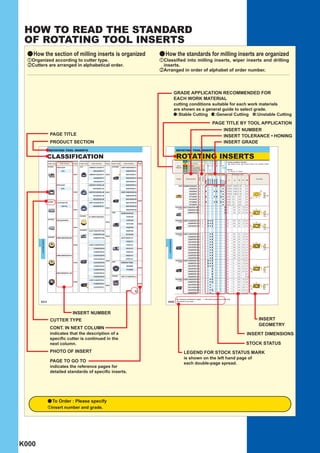

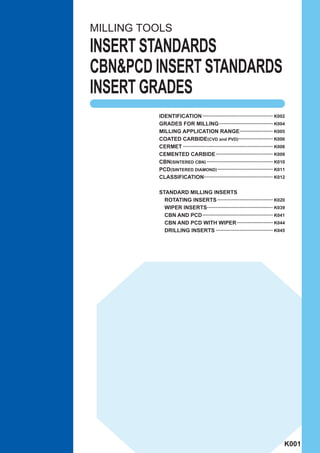

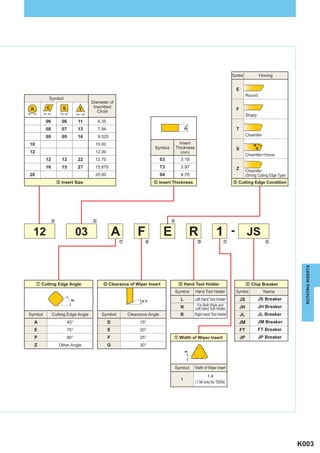

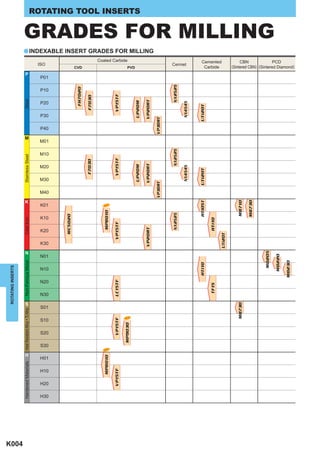

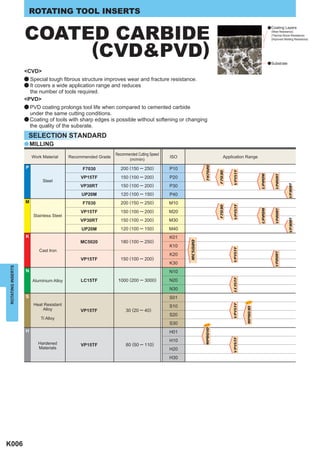

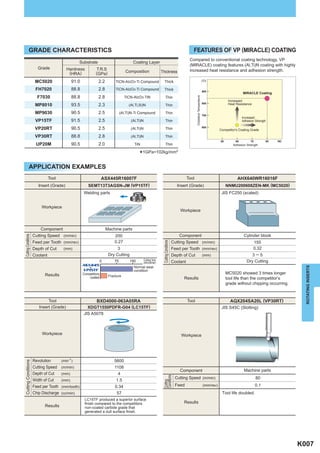

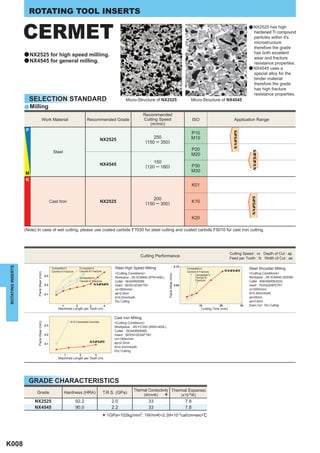

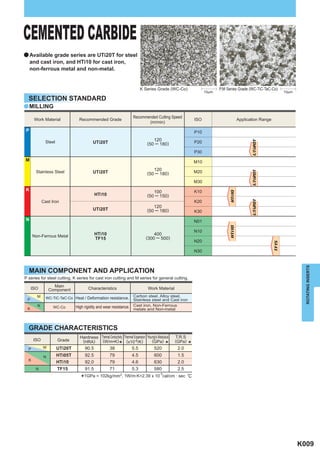

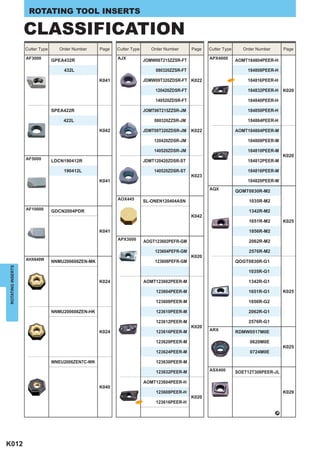

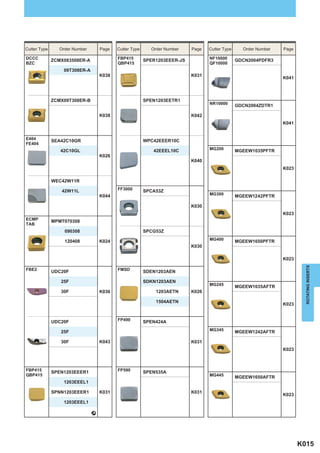

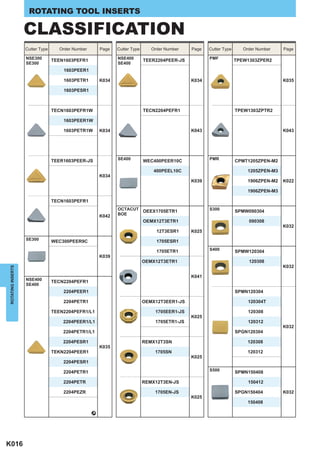

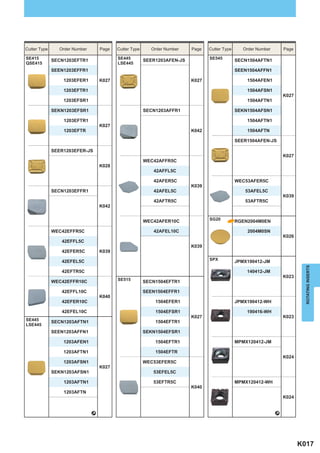

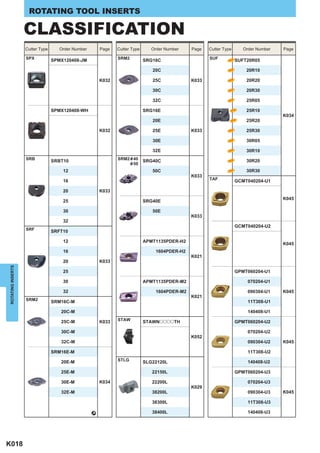

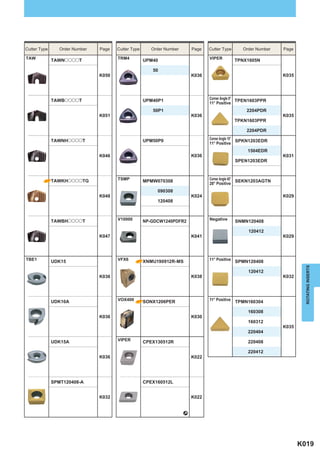

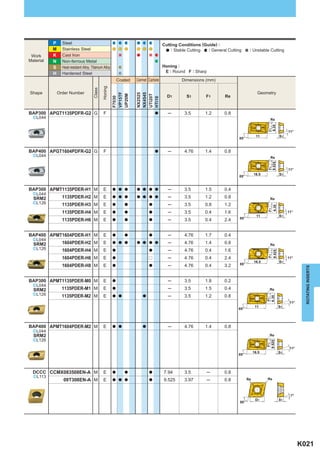

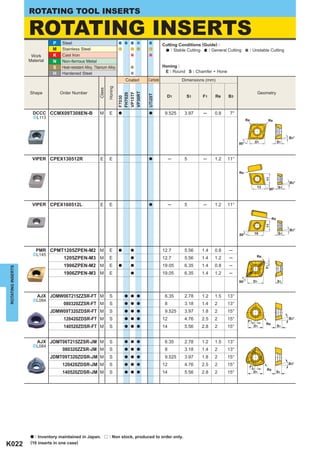

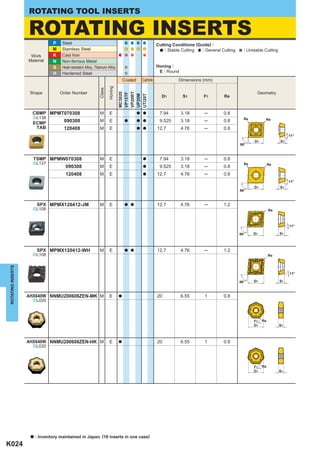

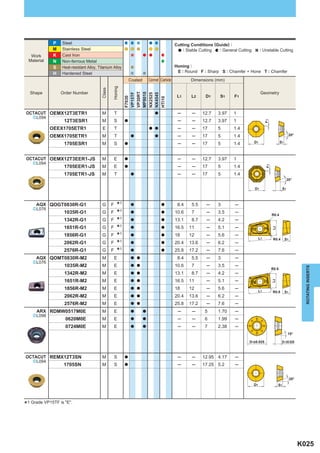

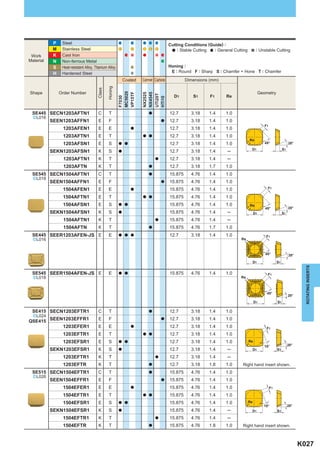

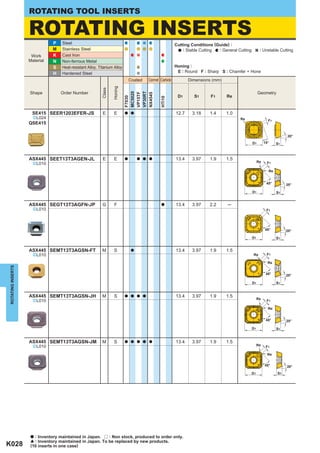

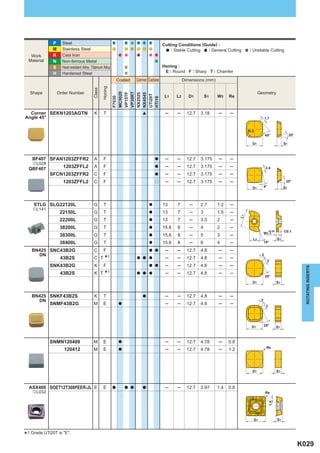

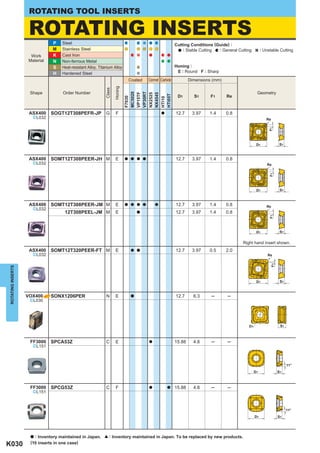

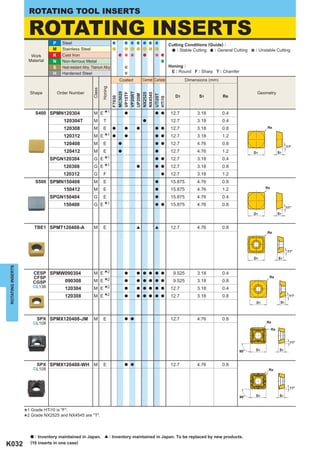

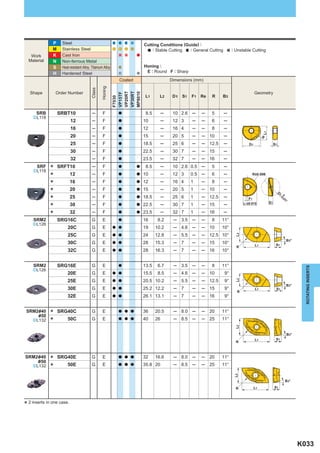

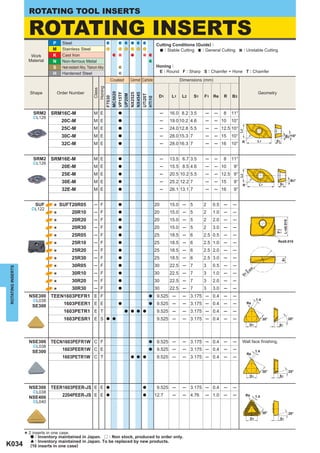

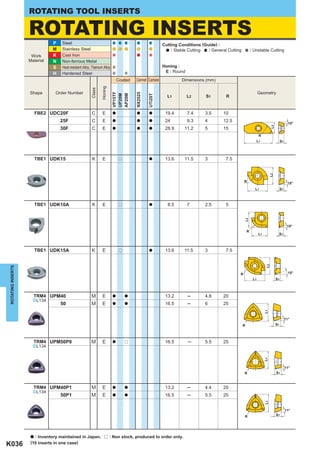

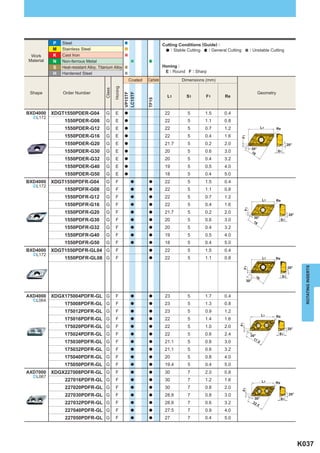

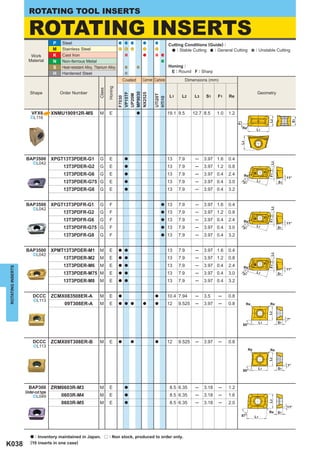

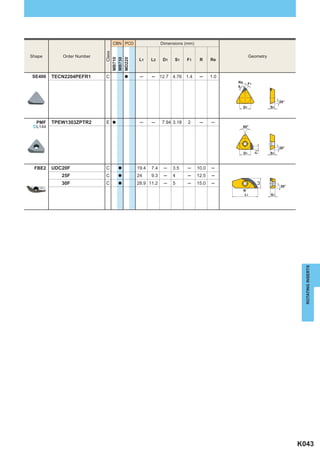

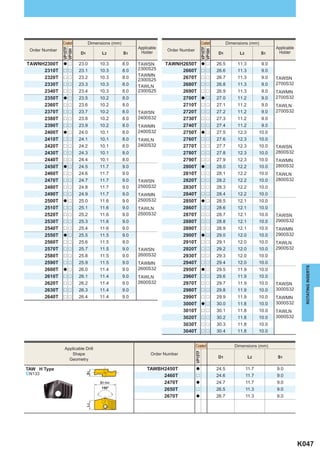

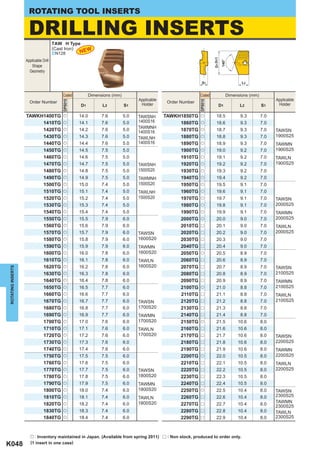

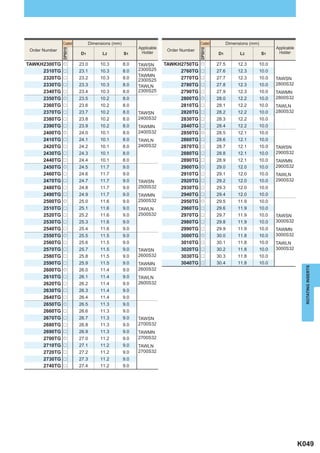

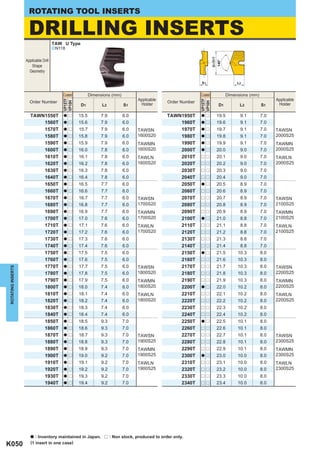

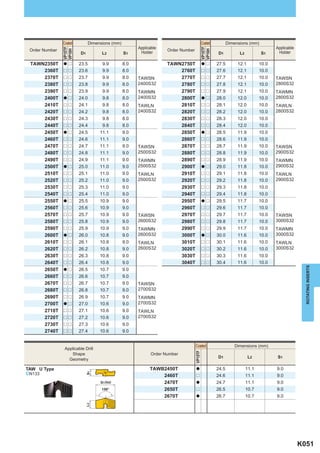

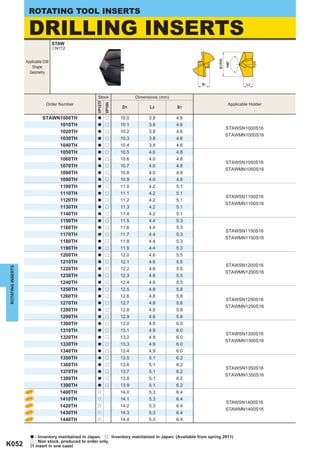

The document provides information on how to read standards for rotating tool inserts. It is organized by cutter type, with cutters arranged alphabetically. Milling inserts, wiper inserts, and drilling inserts are classified. The document also provides information on insert identification, grades for different materials, application ranges, coated vs. cermet vs. cemented carbide inserts, and CBN and PCD inserts. Dimensions, tolerances, and stock statuses are defined.