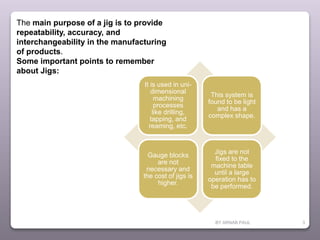

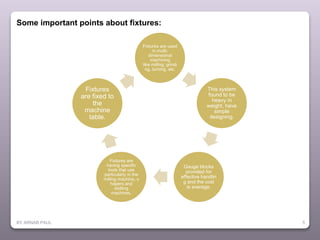

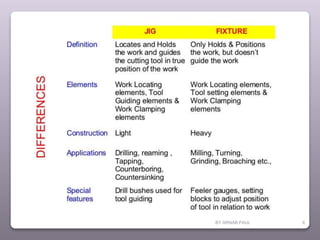

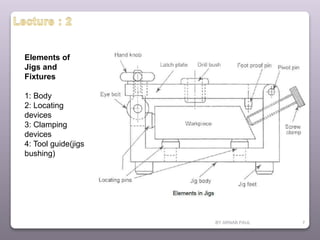

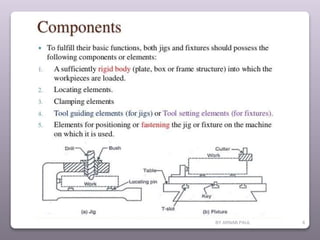

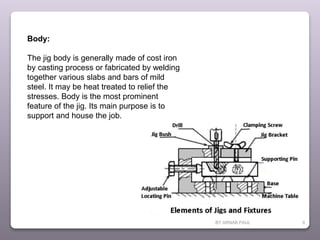

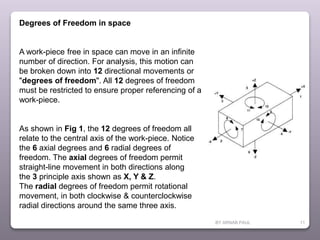

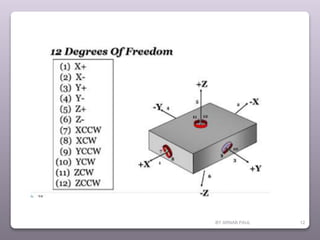

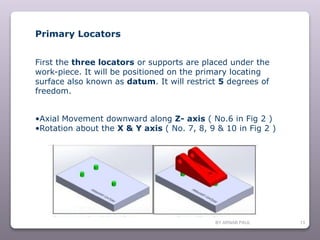

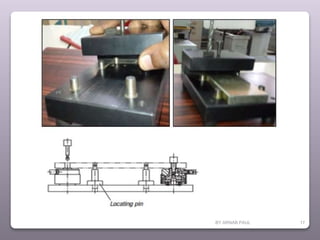

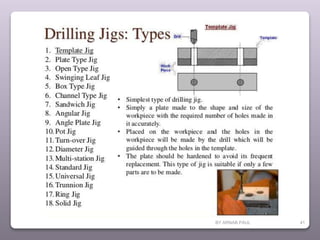

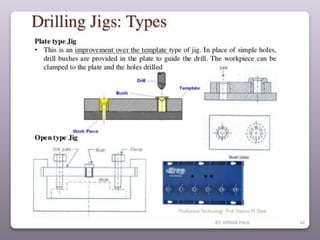

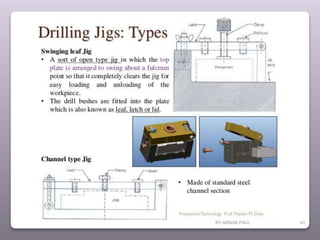

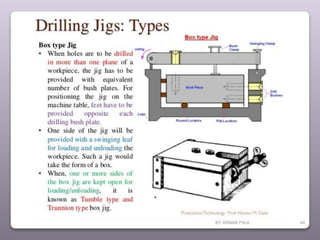

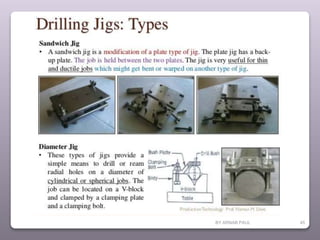

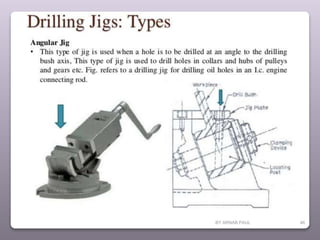

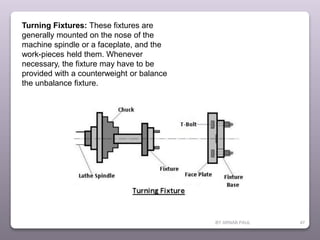

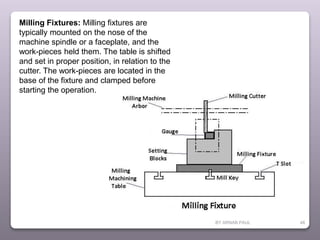

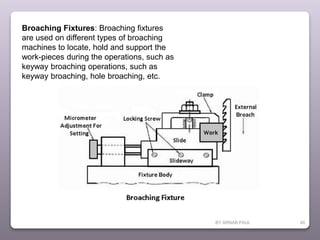

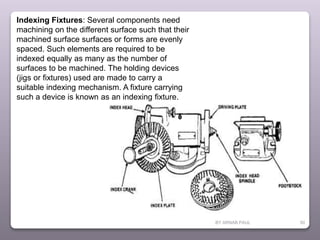

The document defines jigs and fixtures, their purposes and key differences. Jigs hold and guide tools during machining operations while fixtures only hold workpieces. Both aim to provide repeatability, accuracy and interchangeability in manufacturing. The document also describes various types of jigs and fixtures used for different machining processes like turning, milling, grinding and their elements.