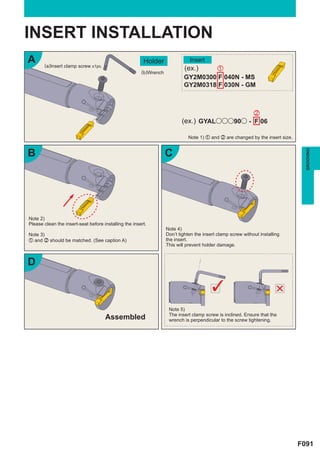

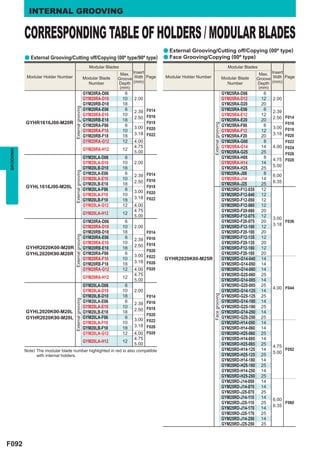

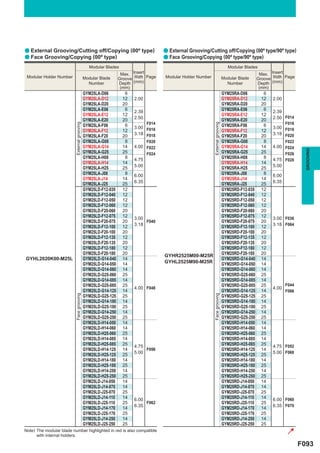

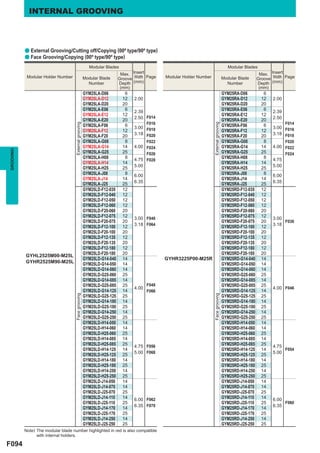

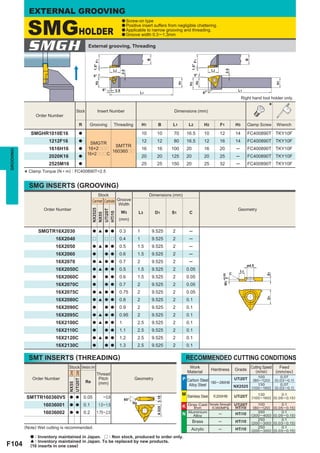

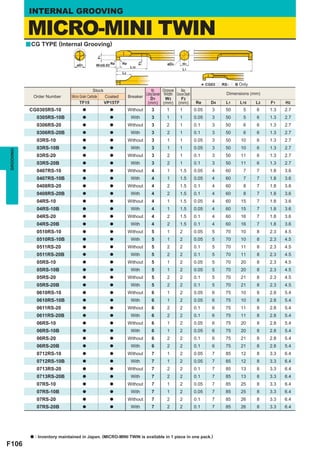

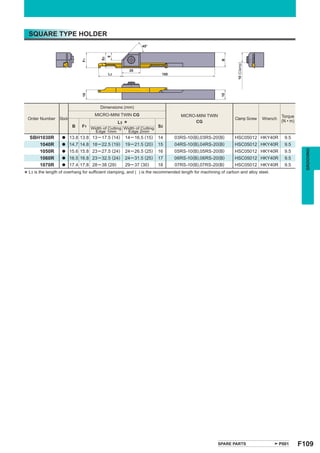

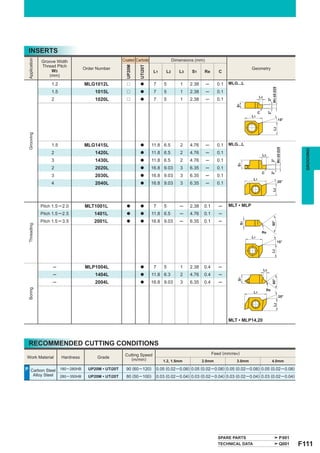

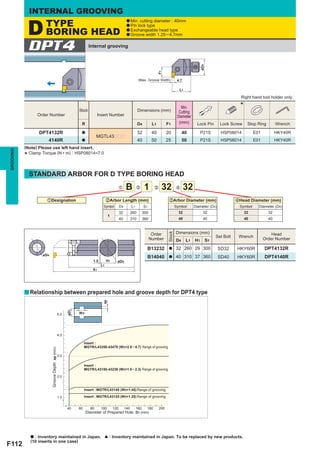

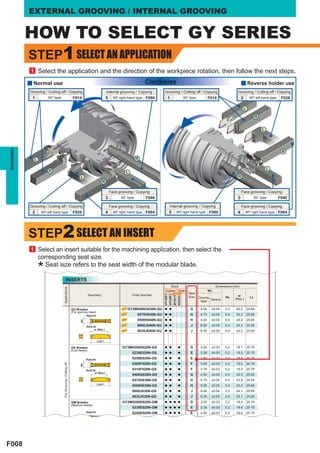

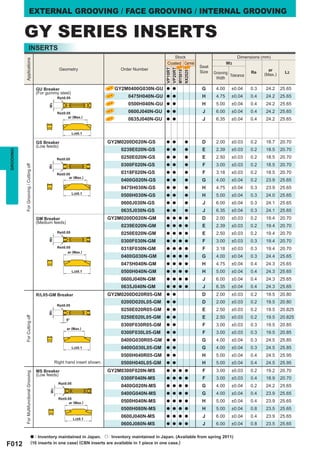

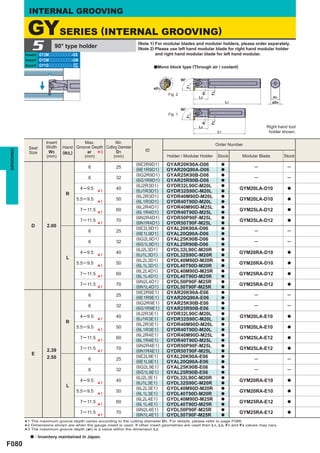

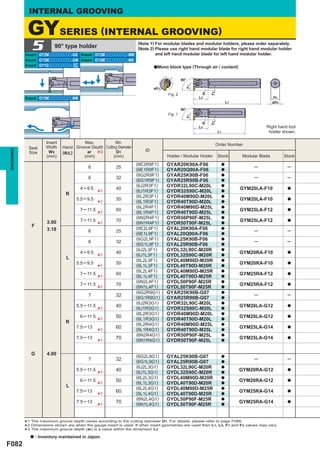

This document provides information on how to read the standard for grooving. It is organized by external and internal grooving applications and further classified by product series. For external grooving, it indicates holder types and available machining applications through illustrations and arrows. Product sections show the geometry and features for different external grooving inserts. For internal grooving, it provides the minimum cutting diameter, holder type as either corner or geometry type, and specifications for each type.

![HOW TO READ THE STANDARD

OF GROOVING

aHow this section page is organized

zClassified according to external or internal applications.

xSub-classified according to product series.

(Refer to the index on the next page.)

[For External Grooving] [For Internal Grooving]

FIGURE SHOWING THE TOOLING APPLICATION

uses illustrations and arrows to depict available machining MIN. CUTTING

applications such as cutting off, grooving, and copying. DIAMETER

INDICATION OF HOLDER TYPE ACCORDING TO APPLICATION is colour-coded to let

indicates the holder types, such as the standard type or the L type, you find, at a glance,

according to machining application. the minimum cutting

TITLE OF PRODUCT PRODUCT FEATURES diameters for internal

INDICATION OF EXTERNAL/

machining.

PRODUCT SECTION FACE GROOVING/INTERNAL

APPLICATION GEOMETRY

EXTERNAL GROOVING INTERNAL GROOVING

GYSERIES (EXTERNAL GROOVING) FTYPE

a Min. cutting diameter 10mm

a Screw-on type

a Usable for various applications.

a Max. groove depth : 3mm

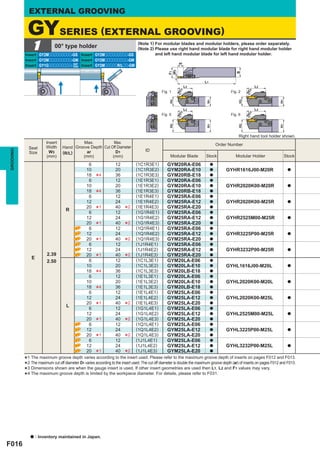

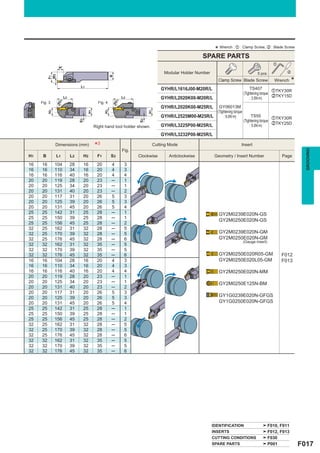

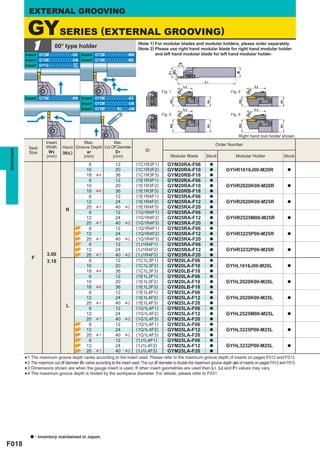

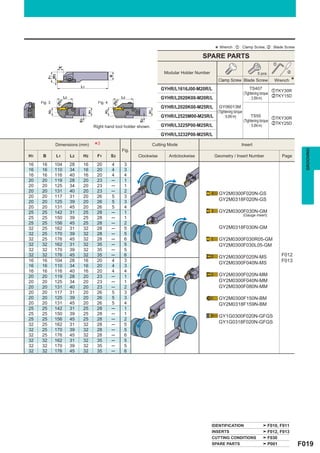

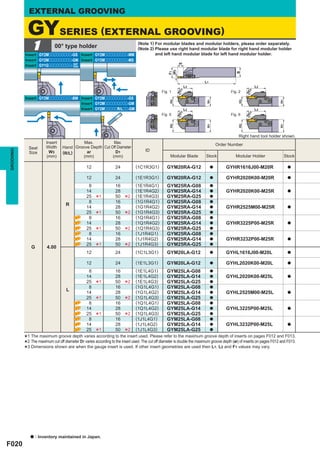

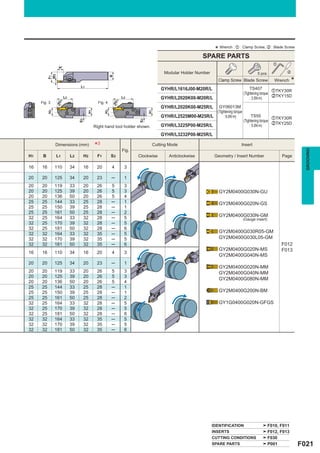

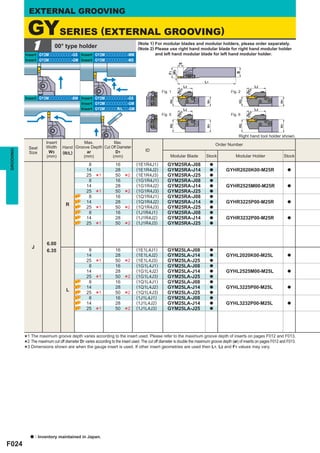

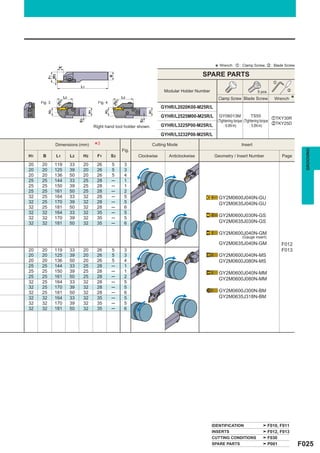

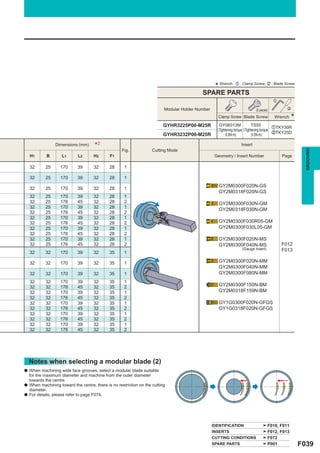

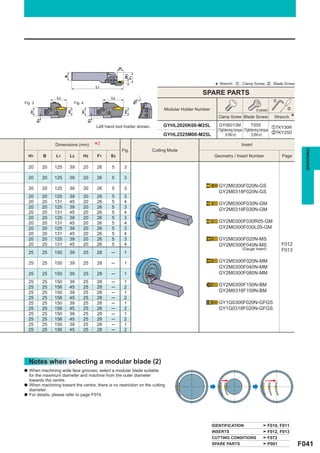

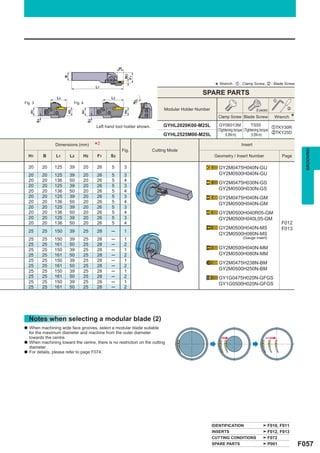

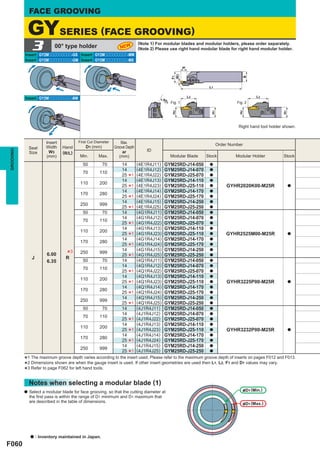

1 00° type holder

Insert GY2Mooooooooo-GS Insert GY2Mooooooooo-GS

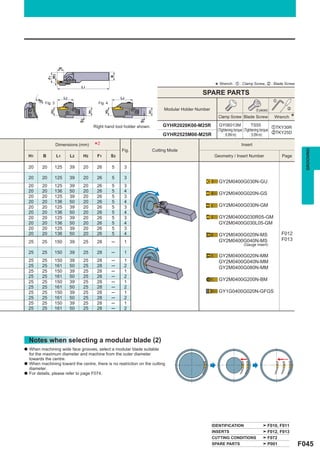

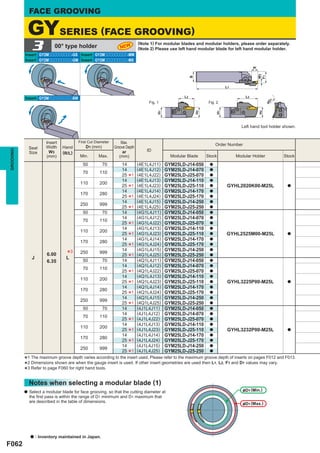

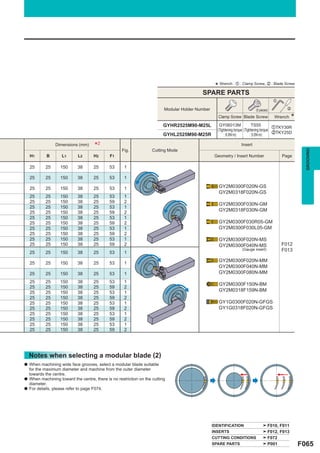

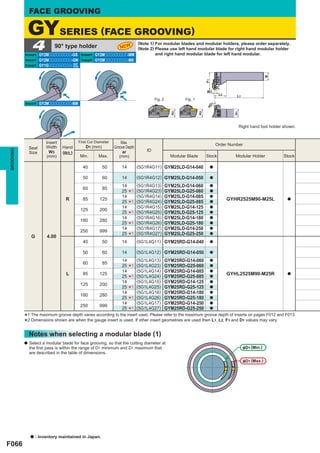

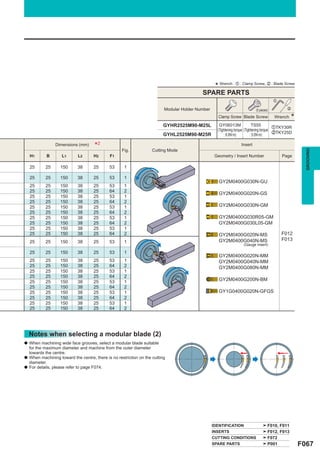

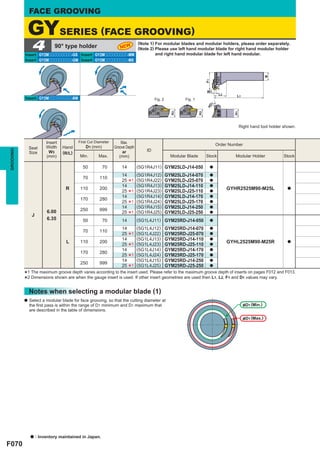

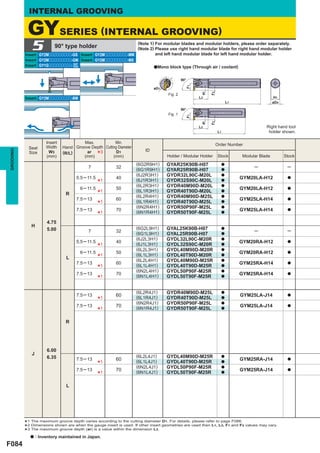

(Note 1) For modular blades and modular holders, please order separately.

(Note 2) Please use right hand modular blade for right hand modular holder

and left hand modular blade for left hand modular holder.

FSL51 Internal grooving, Threading, Boring

Insert GY2Mooooooooo-GM Insert GY2Mooooooooo-GM 1 Corner type (FSL5108R,5110R) 2 Corner type (FSL5112R,5114R,5116R)

ar

Insert GY1Gooooooooo- GF Insert GY2MoooooR/Loo-GM

GS

W3

F1

B

F1

F1

2° 2° 2° 2°

L1 W3 H1 H1

10° L2 W3

L2 L2 L1 øD4 5° L2

1 1 L1 øD4

Fig. 1 øD Fig. 2 øD

Right hand tool holder only.

H2

H2

H1

H1

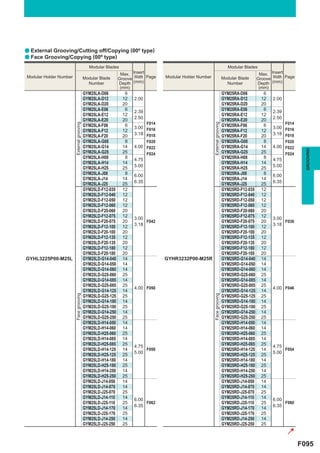

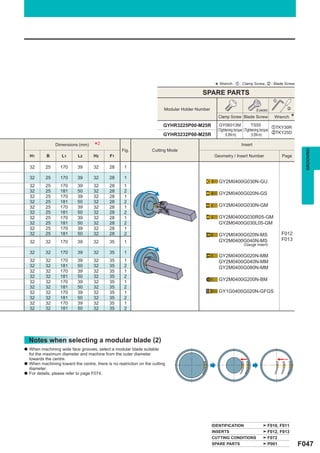

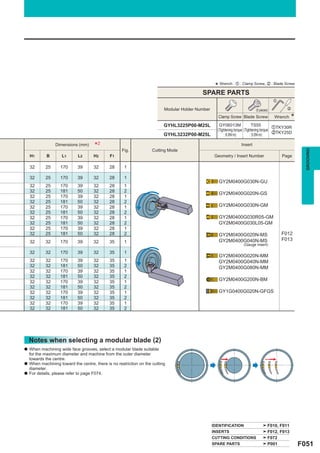

L2 L2 Stock Insert Number Dimensions (mm)

Min. Max. *

1 1 Cutting Groove

Fig. 5 øD Fig. 6 øD Order Number Diameter Depth

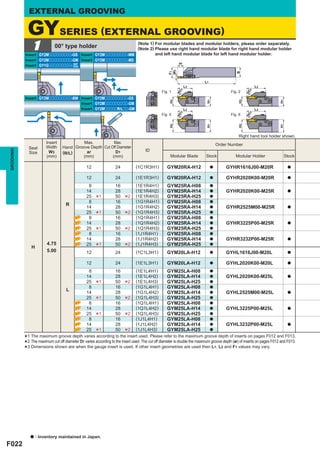

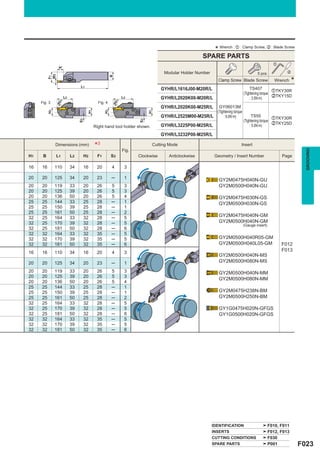

R Grooving Threading Boring D4 L1 L2 F1 H1 W3 (mm) (mm) Clamp Wrench

H2

H2

H1

H1

Screw

FSL5108R a MLG10ppL MLT1001L MLP1004L 8 125 30 4.8 7 1.2 10 1.0 TS25 TKY08F

Right hand tool holder shown. 1.5

Insert Max. Max.

5110R a MLG10ppL MLT1001L MLP1004L 10 150 40 5.8 9 2.0 12 1.0 TS25 TKY08F

Order Number

Seat Width Hand Groove Depth Cut Off Diameter 5112R a MLG14ppL MLT1401L MLP1404L 12 180 50 6.8 10.8 1.5 14 2.0 TS32 TKY08F

GROOVING

GROOVING

W3 ar D1 ID 2.0

Size (R/L)

(mm) (mm) (mm) Modular Blade Stock Modular Holder Stock 5114R a MLG14ppL MLT1401L MLP1404L 14 180 60 7.8 12.4 3.0 16 2.0 TS32 TKY08F

(1C1R3E1) a

2.0

6 12 GYM20RA-E06 5116R a MLG20ppL MLT2001L MLP2004L 16 200 70 9.7 14 3.0 20 3.0 TS43 TKY15F

10 20 (1C1R3E2) GYM20RA-E10 a GYHR1616J00-M20R a

4.0

18 36 (1C1R3E3) GYM20RB-E18 a

6

*4 12 (1E1R3E1) GYM20RA-E06 a * Clamp Torque (N • m) : TS25=1.0, TS32=1.0, TS43=3.5

10 20 (1E1R3E2) GYM20RA-E10 a GYHR2020K00-M20R a

18 4 36 (1E1R3E3) GYM20RB-E18 a

*

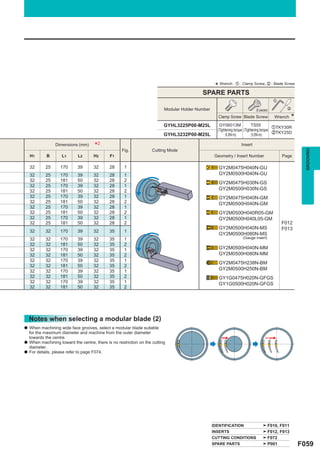

FSL52

6 12 (1E1R4E1) GYM25RA-E06 a

12 24 (1E1R4E2) GYM25RA-E12 a GYHR2020K00-M25R a (Carbide shank) Internal grooving, Threading, Boring

20 40 (1E1R4E3) GYM25RA-E20 a

R

6

*1 12

*2 (1G1R4E1) GYM25RA-E06 a

1 Corner type (FSL5208R,5210R) 2 Corner type (FSL5212R,5214R,5216R)

12 24 (1G1R4E2) GYM25RA-E12 a GYHR2525M00-M25R a

20 40 (1G1R4E3) GYM25RA-E20 a

6

*1 12

*2 (1Q1R4E1) GYM25RA-E06 a

F1

F1

12 24 (1Q1R4E2) GYM25RA-E12 a GYHR3225P00-M25R a

2° 2° 2° 2°

20 40 (1Q1R4E3) GYM25RA-E20 a

6

*1 12

*2 (1J1R4E1) GYM25RA-E06 a

10° W3

L2

L1

H1

øD4 5°

W3

L2

L1

H1

øD4

12 24 (1J1R4E2) GYM25RA-E12 a GYHR3232P00-M25R a

2.39 20 40 (1J1R4E3) GYM25RA-E20 a Right hand tool holder only.

E

6

*1 12

*2 (1C1L3E1) GYM20LA-E06 a

2.50

10 20 (1C1L3E2) GYM20LA-E10 a GYHL1616J00-M20L a

Stock Insert Number Dimensions (mm)

Min. Max. *

(1C1L3E3) a

Cutting Groove

18 36 GYM20LB-E18

6

*4 12 (1E1L3E1) GYM20LA-E06 a

Order Number Diameter Depth

Clamp

10 20 (1E1L3E2) GYM20LA-E10 a GYHL2020K00-M20L a R Grooving Threading Boring D4 L1 L2 F1 H1 W3 (mm) (mm) Screw Wrench

18 4 36 (1E1L3E3) GYM20LB-E18 a

6

* 12 (1E1L4E1) GYM25LA-E06 a

FSL5208R a MLG10ppL MLT1001L MLP1004L 8 125 60 4.8 7 1.2

1.5

10 1.0 TS25 TKY08F

12 24 (1E1L4E2) GYM25LA-E12 a GYHL2020K00-M25L a 5210R a MLG10ppL MLT1001L MLP1004L 10 150 70 5.8 9 2.0 12 1.0 TS25 TKY08F

20 40 (1E1L4E3) GYM25LA-E20 a

L

6

*1 12

*2 (1G1L4E1) GYM25LA-E06 a

5212R a MLG14ppL MLT1401L MLP1404L 12 180 80 6.8 10.8 1.5

2.0

14 2.0 TS32 TKY08F

12 24 (1G1L4E2) GYM25LA-E12 a GYHL2525M00-M25L a 5214R a MLG14ppL MLT1401L MLP1404L 14 180 85 7.8 12.4 3.0 16 2.0 TS32 TKY08F

20 1 40 2 (1G1L4E3) GYM25LA-E20 a 2.0

6

* 12

* (1Q1L4E1) GYM25LA-E06 a 5216R a MLG20ppL MLT2001L MLP2004L 16 200 115 9.7 14 3.0 20 3.0 TS43 TKY15F

12 24 (1Q1L4E2) GYM25LA-E12 a GYHL3225P00-M25L a 4.0

(1Q1L4E3)

20

6

*1 40

12

*2 (1J1L4E1)

GYM25LA-E20

GYM25LA-E06

a

a

* Clamp Torque (N • m) : TS25=1.0, TS32=1.0, TS43=3.5

12 24 (1J1L4E2) GYM25LA-E12 a GYHL3232P00-M25L a

20 40 (1J1L4E3) GYM25LA-E20 a

*1 *2

*2 The maximum cutgroove depth1varies according to to the insert used.cut off diameter is double the maximum groove depth (ar) of insertspages F012 and F013.

1 The maximum according Please refer to the maximum groove depth of inserts on

*3 Dimensions shown are whenvariesgauge insert isinsert used.other insert geometries are used then L1, L2 and F1 values maypages F012 and F013.

off diameter D

the

the

used. If

The on

vary.

*4 The maximum groove depth is limited by the workpiece diameter. For details, please refer to F031.

*

a : Inventory maintained in Japan. a : Inventory maintained in Japan. r : Non stock, produced to order only.

(10 inserts in one case)

F016 F110

PRODUCT STANDARDS LEGEND FOR

indicates order numbers, stock status STOCK STATUS MARK

(per right/left hand), holders, Modular Blade, is shown on the left hand

groove widths, maximum groove depths, page of each double-page

maximum cut-off diameters, dimensions, spread.

applicable inserts, and cutting edge shapes.

a To Order : For holder, please specify zorder number and hand of tool (right/left).

For insert, please specify zinsert number and xgrade.

F000](https://image.slidesharecdn.com/grooving-130112060920-phpapp01/75/GROOVING-1-2048.jpg)

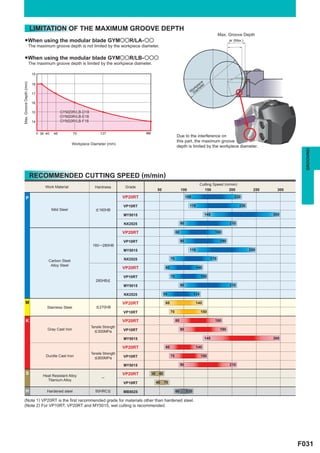

![EXTERNAL GROOVING

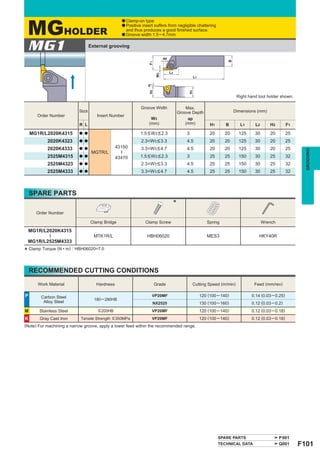

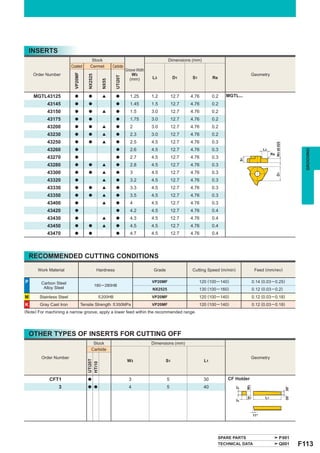

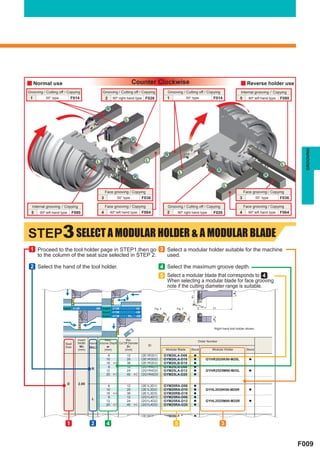

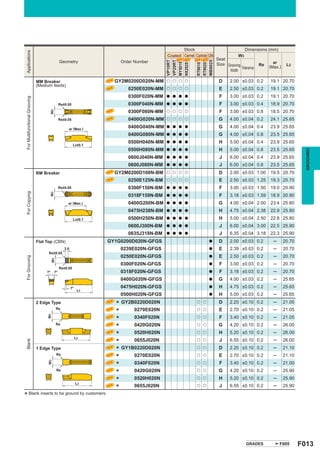

RECOMMENDED CUTTING CONDITIONS [For External Grooving] *the modular holder GYHR/L2525M00-M25R/L with the

Below are the recommended cutting conditions when using

modular blade GYM25oA-oo.

y Recommended feed rate and depth of cut

GU BREAKER GS BREAKER GM BREAKER FLAT TOP GFGS (CBN)

a Grooving, Cutting off a Grooving, Cutting off a Grooving, Cutting off a Grooving

6.35 6.35 6.35

6.0 6.0 6.0

5.0 5.0

Insert width (mm)

Insert width (mm)

Insert width (mm)

Insert width (mm)

5.0 5.0

4.75 4.75 4.75 4.75

4.0 4.0 4.0 4.0

3.18 3.18 3.18

3.0 3.0 3.0

2.5 2.5 2.5

2.39 2.39 2.39

2.0 2.0 2.0

0 0.05 0.1 0.2 0 0.05 0.1 0.2 0.3 0 0.1 0.2 0.3 0.4 0 0.05 0.1 0.15

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

: 1st recommended area

MS BREAKER

a Grooving a Turning

GROOVING

: 1st 4.0

Radial Depth of cut (mm)

recommended area

6.0

Insert width 6mm

Insert width (mm)

3.0

5.0 Insert width 5mm

Insert width 4mm

2.0

4.0

3.0 1.0

Insert width 3mm

0 0.1 0.2 0.3 0.4 0 0.1 0.2 0.3 0.4

Feed (mm/rev) Feed (mm/rev)

MM BREAKER

a Grooving a Turning

: 1st 4.0

Radial Depth of cut (mm)

6.0 recommended area

Insert width 6mm

Insert width (mm)

5.0 3.0 Insert width 5mm

4.0 Insert width 4mm

2.0

3.0 Insert width

3mm

2.5

1.0

2.0 Insert width 2.5mm

Insert width 2mm

0 0.1 0.2 0.3 0.4 0 0.1 0.2 0.3 0.4

Feed (mm/rev) Feed (mm/rev)

BM BREAKER

a Grooving a Turning

6.35 : 1st 4.0

6.0

Radial Depth of cut (mm)

recommended area

Insert width

5.0

Insert width (mm)

5.0mm

4.75 3.0 4.75mm Insert width

Insert width 6.35mm

4.0 4.0mm

6.0mm

3.18 2.0

3.0 Insert width

3.18mm

2.5 3.0mm

Insert width

1.0 2.5mm

2.0 Insert width

2.0mm

0 0.1 0.2 0.3 0.4 0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8

Feed (mm/rev) Feed (mm/rev)

(Note) When using a combination as shown below, decrease the recommended feed rate by 20% and 40% respectively.

a Decrease the feed rate by 20%. a Decrease the feed rate by 40%.

20mm

20mm

16mm

GYHR2020K00-M25R GYHR2020K00-M20R GYHR1616J00-M20R

GYM25 GYM20 GYM20

(20mm×20mm Square holder) (16mm×16mm Square holder)

F030](https://image.slidesharecdn.com/grooving-130112060920-phpapp01/85/GROOVING-31-320.jpg)

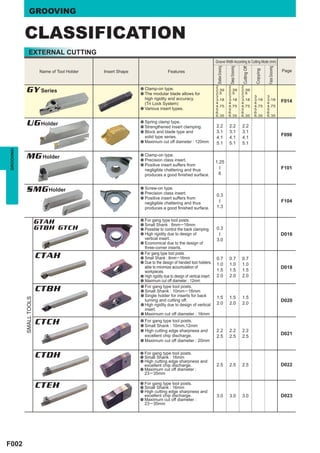

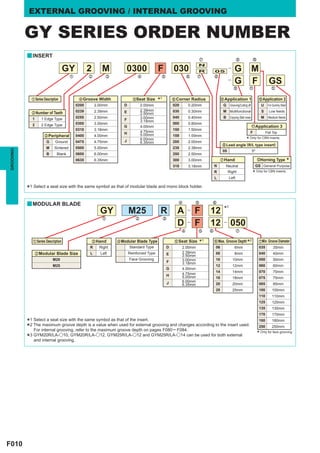

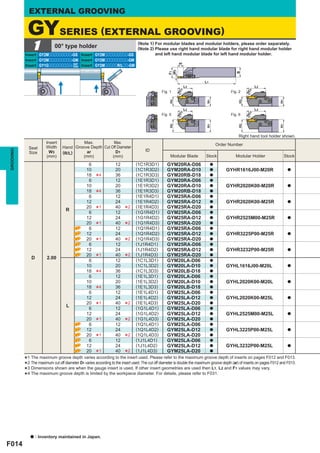

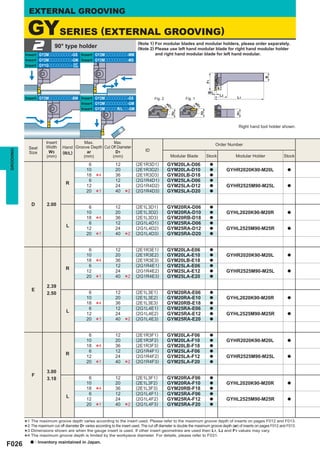

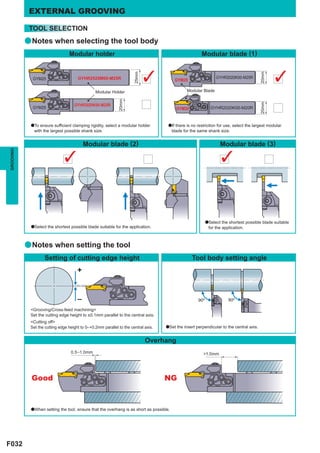

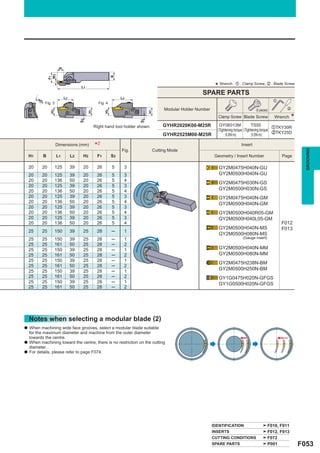

![ASSEMBLY INSTRUCTION

A (b)Wrench

(For Insert clamp screw) Modular Holder Modular Blade

(ex.) x c

(a)Insert clamp

screw x1pc. GY M25R A - F 20

GY M25R A - F 12 Short,

Long Medium

(c)Modular blade (5 holes) (4 holes)

(d)Wrench set screw x5pc.

(For Modular blade Insert v

set screw) (ex.) GY2M0300 F 040N-MS

z

GY2M0318 F 030N-GM

(ex.) GYHR2525M00 - M25R

Note 1) c and v are changed by the insert size.

B

GROOVING

B'

Side Screws

(3 screws) Side Screws

(2 screws)

Short, Medium

Modular Blade

Long (4 holes)

Modular Blade

(5 holes)

Note 2) z and x should be matched. (See caption A)

C D

Front Screws Note 4)

(2 screws) Please clean the insert-seat

before installing the insert.

Note 3)

Note 5)

Please tighten the modular blade

c and v should be matched.

set screws in order of

(See caption A)

[Side screws] → [Front screws].

E F

Note 6)

Don’t tighten the insert

clamp screw without

installing the insert. Note 7)

This will prevent modular The insert clamp screw is inclined. Ensure

blade damage. that the wrench is perpendicular to the

screw tightening. Assembled

F035](https://image.slidesharecdn.com/grooving-130112060920-phpapp01/85/GROOVING-36-320.jpg)

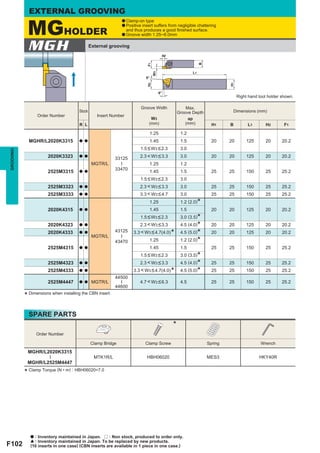

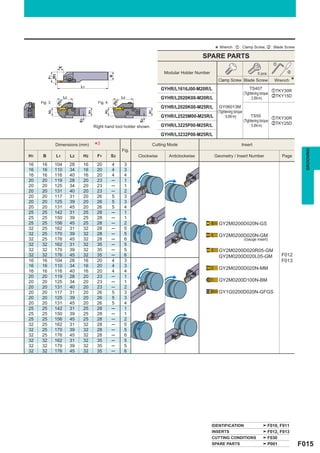

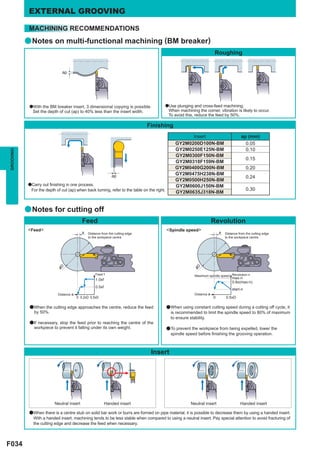

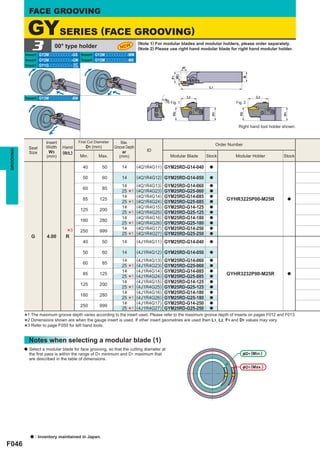

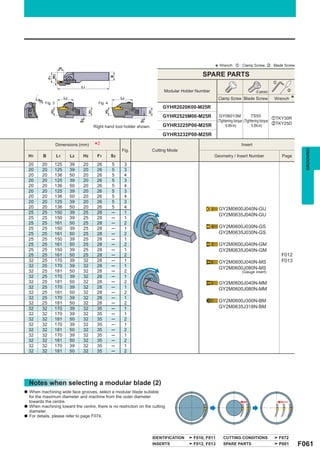

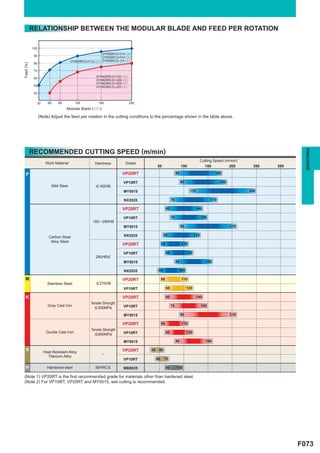

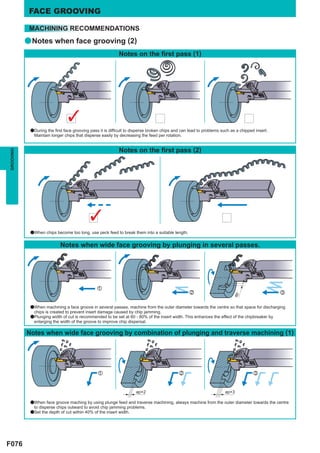

![FACE GROOVING

RECOMMENDED CUTTING CONDITIONS [Face Grooving]

GROOVING

: 1st

6.35 recommended area

6.0

Insert width (mm)

5.0

4.75

4.0

3.18

3.0

0 0.05 0.1 0.15 0.2

Feed (mm/rev)

PLUNGING

: 1st

6.35 recommended area

GROOVING

6.0

Insert width (mm)

5.0

4.75

4.0

3.18

3.0

0 0.05 0.10

Feed (mm/rev)

0.15 0.20 0.25

* set narrower plunge, the with Wof. cut should be

After the 1st

than insert

width

3

TRAVERSE MACHINING (MM/MS BREAKER)

3.0

Insert width 6mm

Axial Depth of Cut (mm)

Insert width 5mm

2.0

Insert width 4mm

1.0

Insert width 3mm

0 0.1 0.2 0.3

Feed (mm/rev)

TRAVERSE MACHINING (BM BREAKER)

3.0

Axial Depth of Cut (mm)

2.0 Insert width 6mm,6.35mm

Insert width

4.75mm,5mm

Insert width

1.0 4mm

Insert width 3mm,3.18mm

0 0.2 0.4 0.6

Feed (mm/rev)

F072](https://image.slidesharecdn.com/grooving-130112060920-phpapp01/85/GROOVING-73-320.jpg)

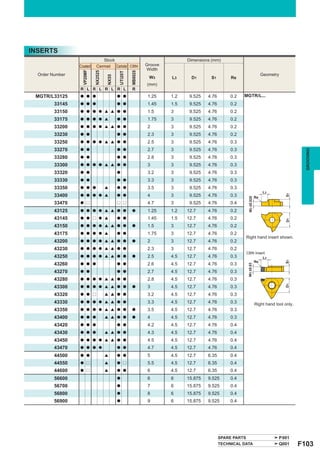

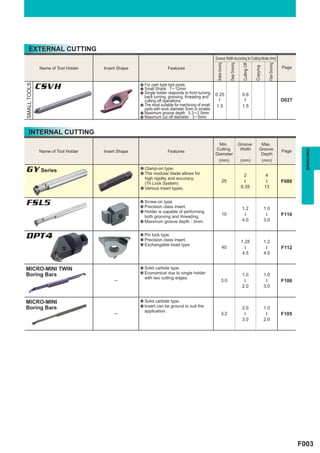

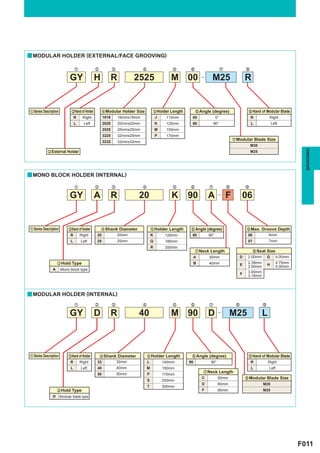

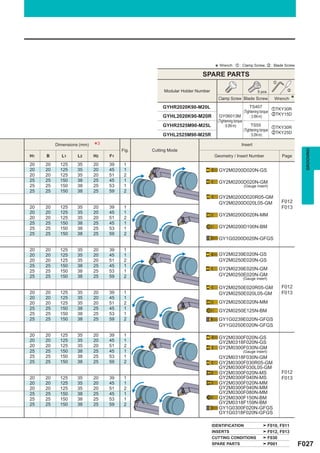

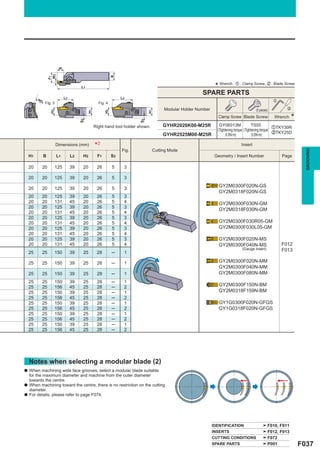

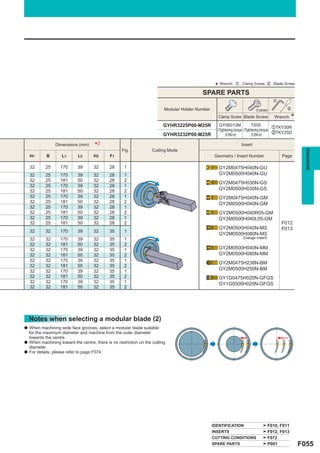

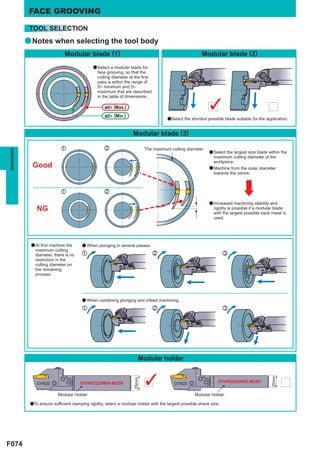

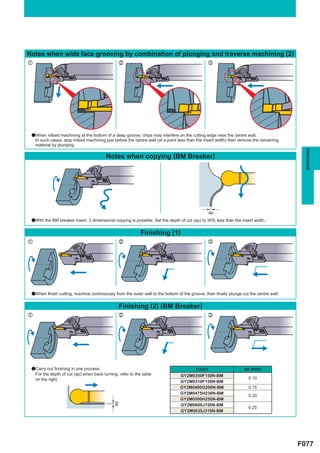

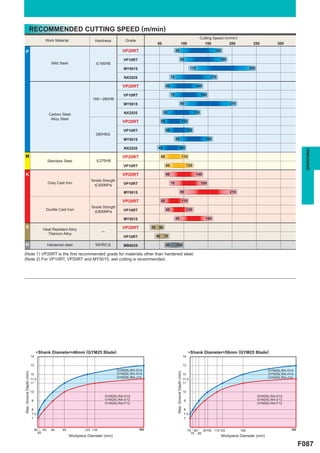

![INTERNAL GROOVING

RECOMMENDED CUTTING CONDITIONS [For Internal Grooving]

GROOVING

(Note 1) The cutting diameter 100% represents the minimum cutting diameter (øD1).

(Note 2) The graph on the left shows the cutting conditions when setting the feed to 100%.

105

: 1st

Shank Diameter D4 (mm)

50 recommended area

100

40

Feed (%)

95

32

90

25

20 85

80

0 0.05 0.1 0.15 0.2 100 150 200 250

Feed (mm/rev) Hole diameter (%)

TRAVERSE MACHINING (MM/MS BREAKER)

a When traverse machining a blind hole, it is recommended to

GROOVING

4.0

carry out back turning considering chip disposal.

Radial Depth of cut (mm)

Insert width 6mm

3.0

Insert width 5mm

Insert width 4mm

2.0

Insert width 3mm

1.0

Insert Width 2.5mm

Insert Width 2mm

0 0.1 0.2 0.3

Feed (mm/rev)

(Note) The above cutting conditions are for when using the tool overhang (L) 1.6-2.0 times larger than the shank diameter (øD4). (L/D=1.6-2.0)

When using L/D larger than 2.0, reduce the cutting conditions.

Tool chuck

&D4

L

LIMITATION OF THE MAXIMUM GROOVE DEPTH

●When using the mono block type

The maximum groove depth is not limited by the cutting diameter.

●When using the modular blade type

The maximum groove depth is limited by the cutting diameter.

Due to interference of this part,

the maximum groove depth is

limited by the cutting diameter.

•Shank Diameter=32mm (GYM20 Blade) • Shank Diameter=40mm (GYM20 Blade)

12 12

11.5 11.5

11 11

GYM20L/RA-G12 GYM20L/RA-G12

10 GYM20L/RA-H12 GYM20L/RA-H12

Max. Groove Depth (mm)

Max. Groove Depth (mm)

10

9

9

8

8

7 GYM20L/RA-D10

GYM20L/RA-D10 7 GYM20L/RA-E10

6 GYM20L/RA-E10 GYM20L/RA-F10

GYM20L/RA-F10

6

5

4.5 5.5

4 5

40 44 55 65 80 90 105 y 50 56 65 80 100 110 130 y

41 48 54

Workpiece Diameter (mm) Workpiece Diameter (mm)

F086](https://image.slidesharecdn.com/grooving-130112060920-phpapp01/85/GROOVING-87-320.jpg)

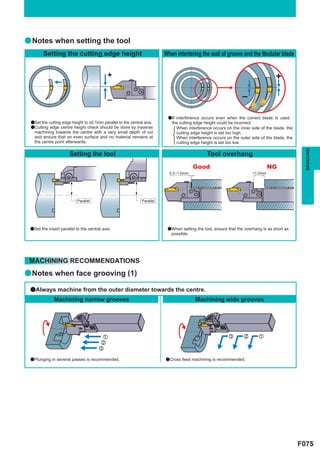

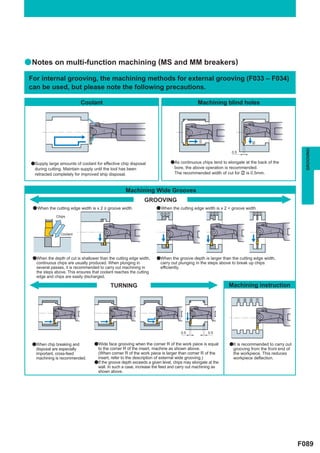

![INTERNAL GROOVING

ASSEMBLY INSTRUCTION

A (a)Insert clamp

screw x1pc.

Modular Holder Modular Blade

(d)Wrench x c

(For Modular blade (ex.) GY M20R A - F 10

set screw) Short,

GY M25R A - F 12 Medium

(4 holes)

(b)Wrench

(c)Modular blade (For Insert Insert v

clamp screw)

set screw x4pc. (ex.) GY2M0300 F 040N-MS

z

(ex.) GYDL40M90D - M20R GY2M0318 F 030N-GM

GYDL40M90D - M25R Note 1) c and v are changed by the insert size.

B C

GROOVING

Side Screws

(2 screws)

Note 3)

Please tighten the modular blade Front Screws

Note 2) set screws in order of (2 screws)

z and x should be matched. (See caption A) [Side screws] → [Front screws].

D Note 4)

Please clean the E

insert-seat before

installing the insert.

Note 5)

c and v should be

matched.

(See caption A) Note 6)

Don’t tighten the insert clamp screw without installing

the insert.

F This will prevent modular blade damage.

Note 7)

The insert clamp screw is inclined. Ensure that the

Assembled wrench is perpendicular to the screw tightening.

F090](https://image.slidesharecdn.com/grooving-130112060920-phpapp01/85/GROOVING-91-320.jpg)