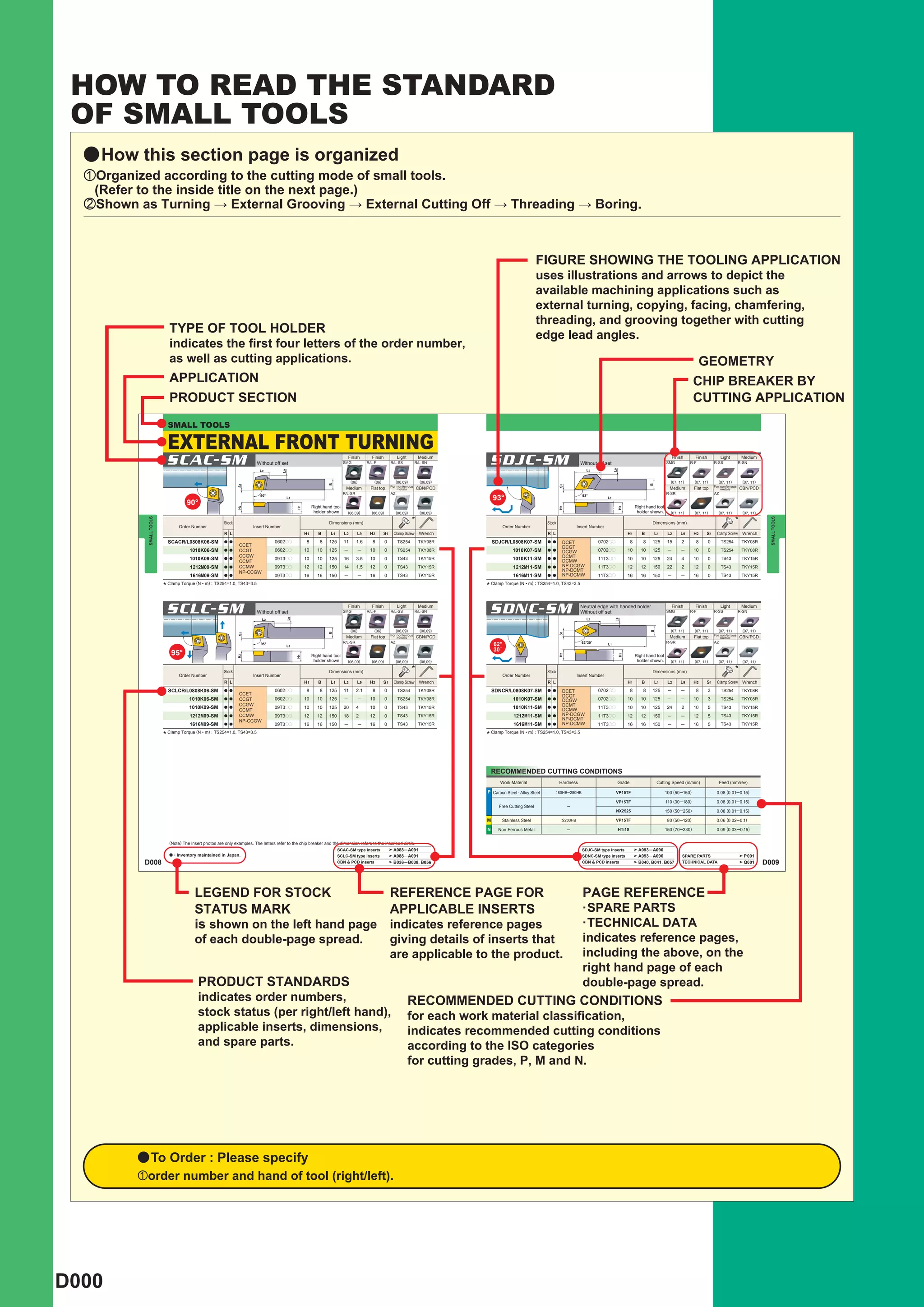

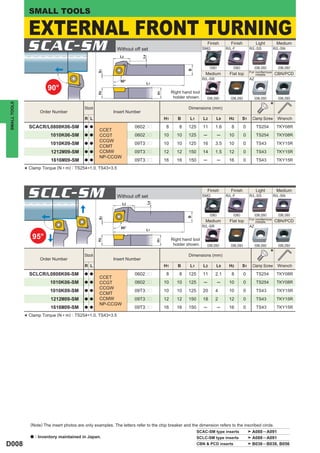

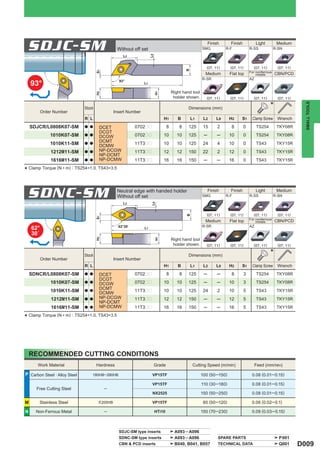

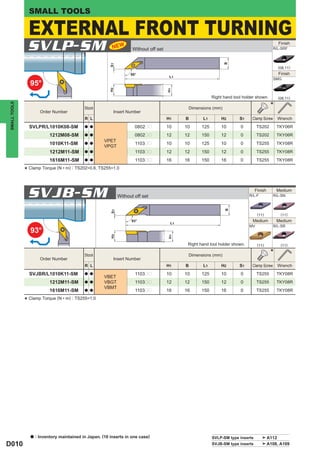

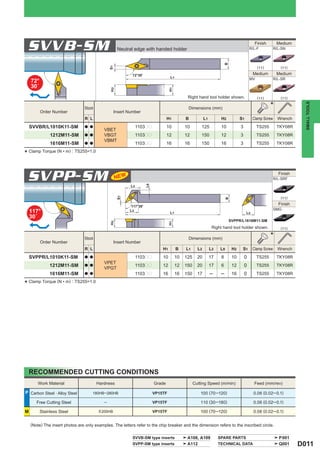

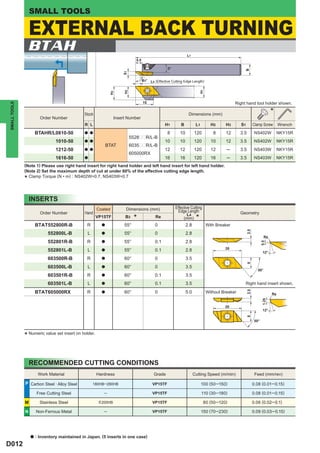

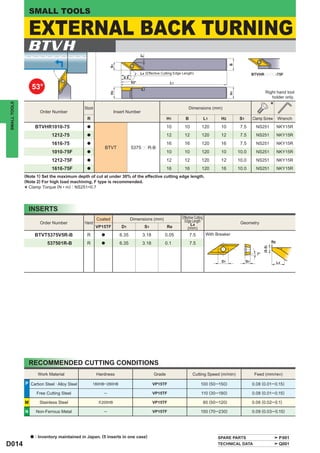

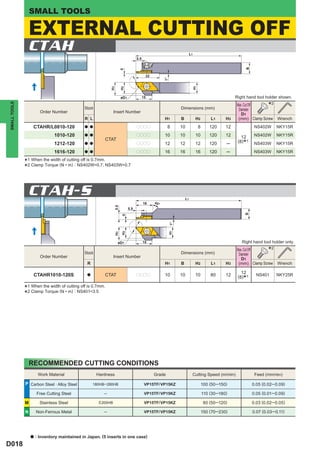

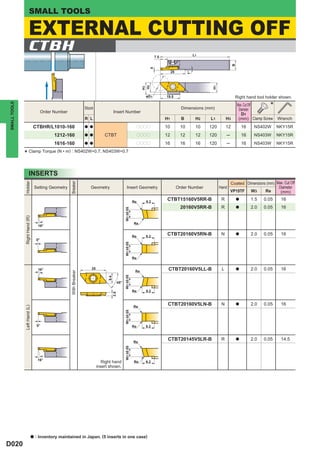

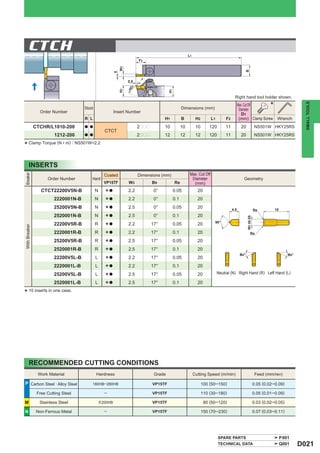

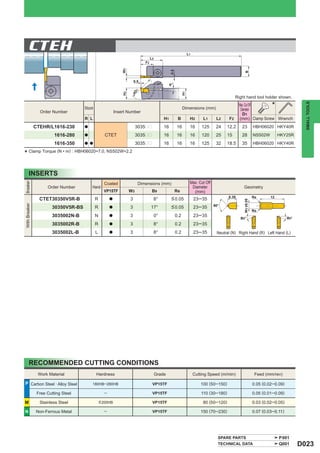

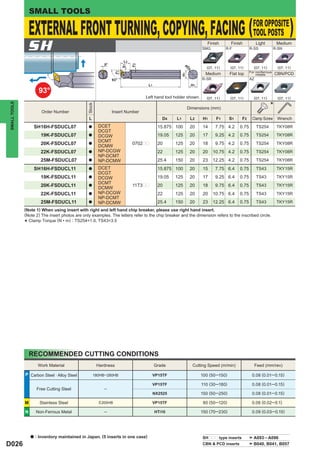

This document provides information on small tools for gang type automatic lathes. It is organized by cutting application, including external turning, back turning, grooving, cutting off, and boring. For each application it provides details on the tool type, insert geometry such as cutting edge width and overhang, and features such as breaker inserts and minus tolerance corners for small parts machining. Recommended cutting conditions are also provided for various work materials.