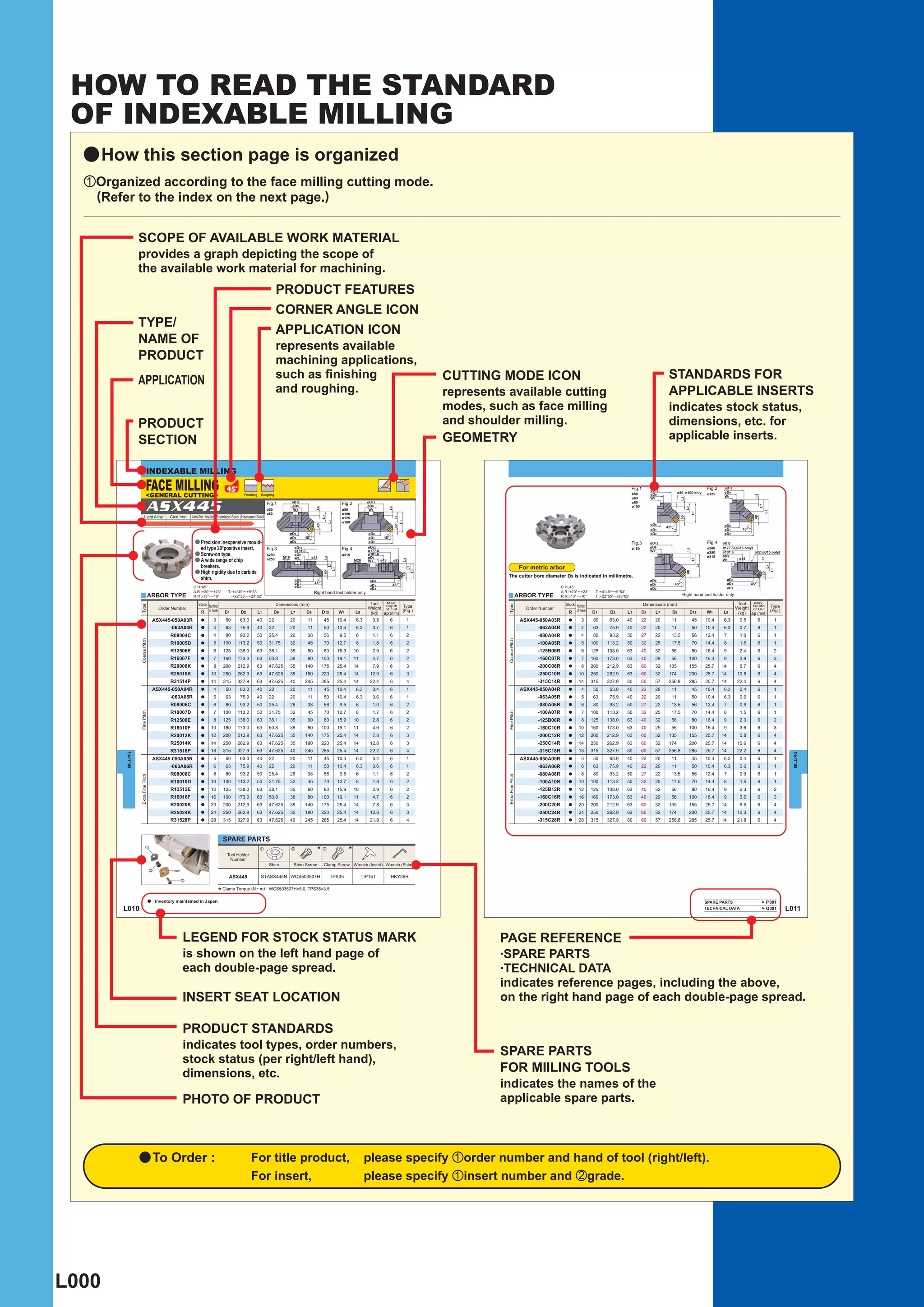

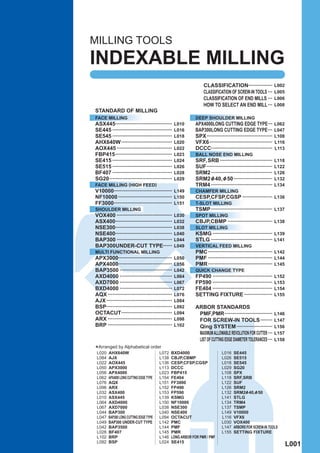

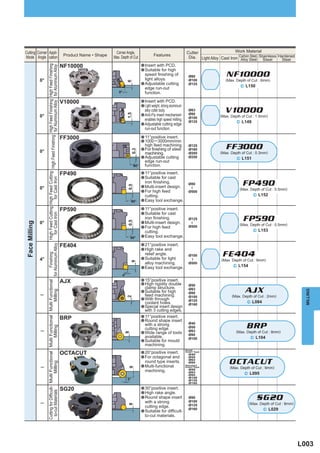

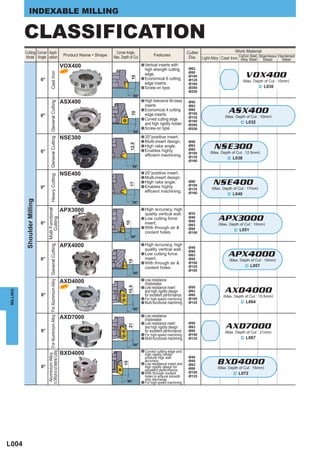

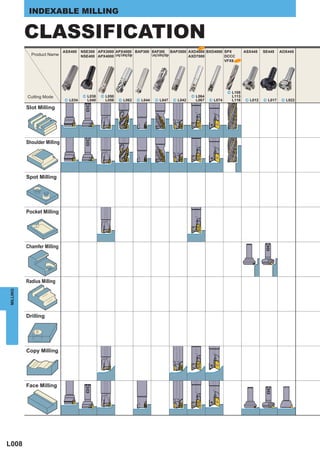

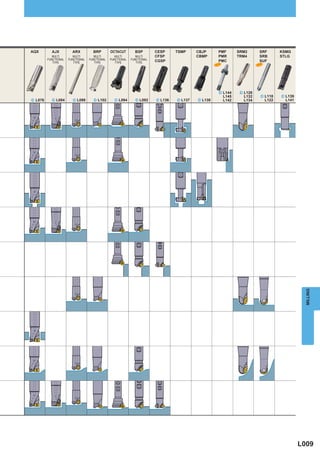

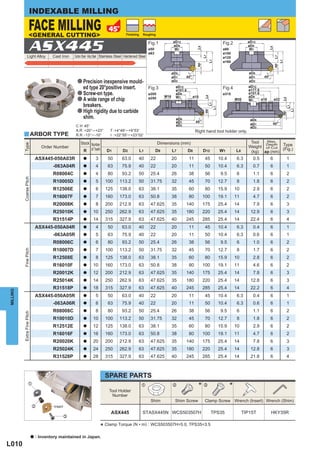

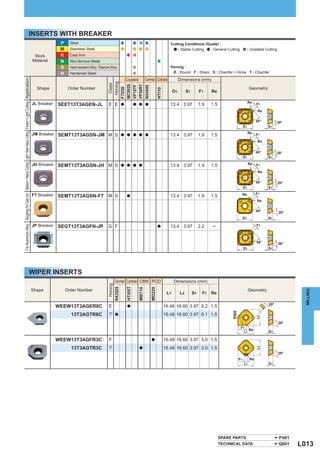

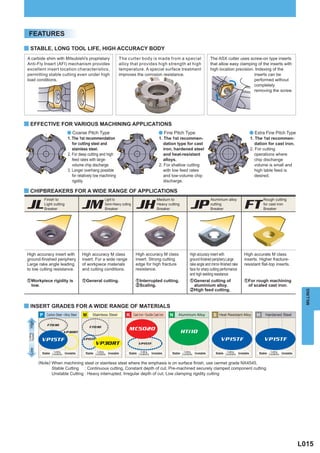

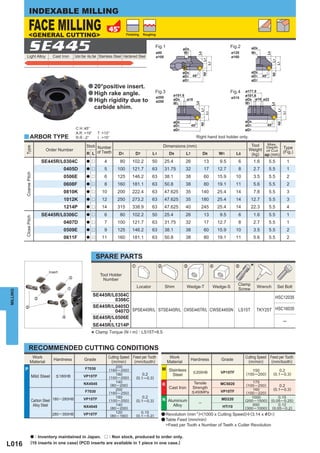

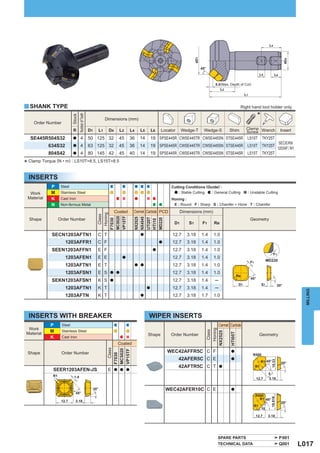

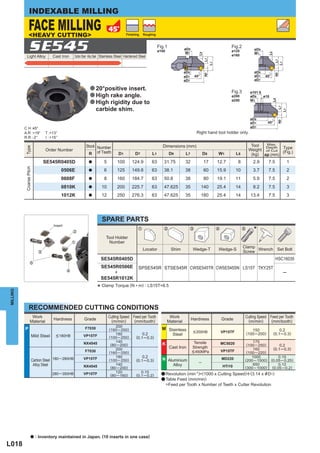

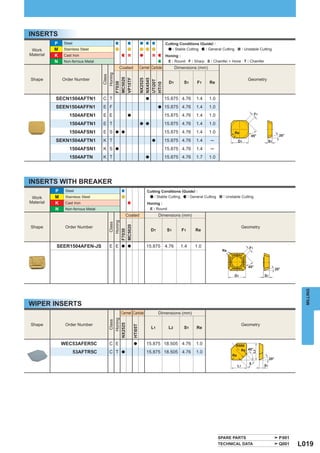

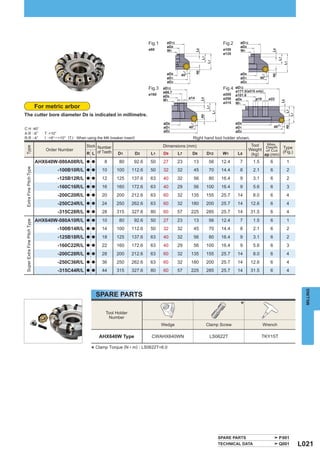

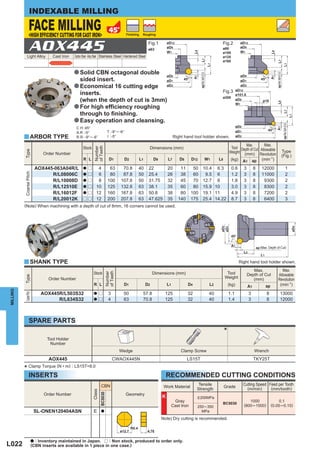

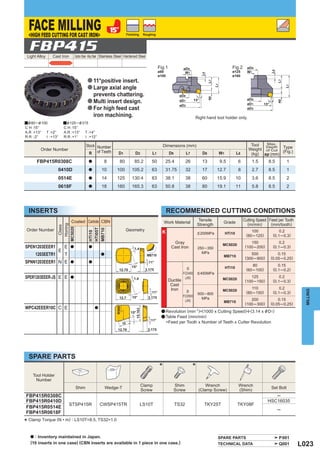

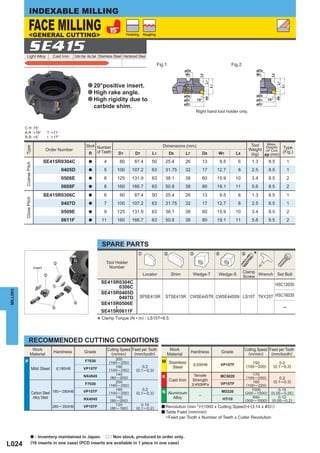

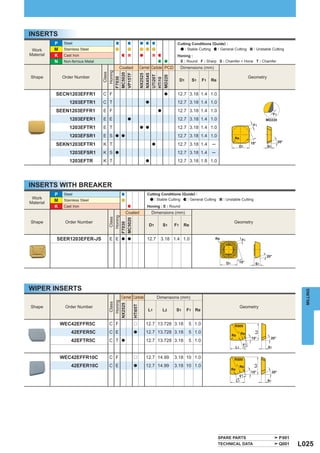

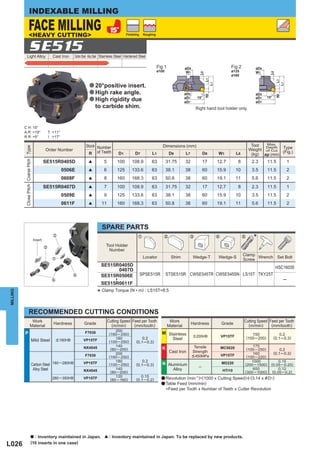

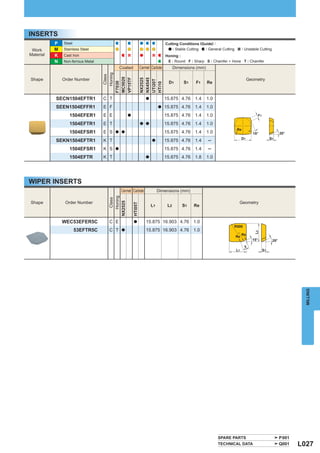

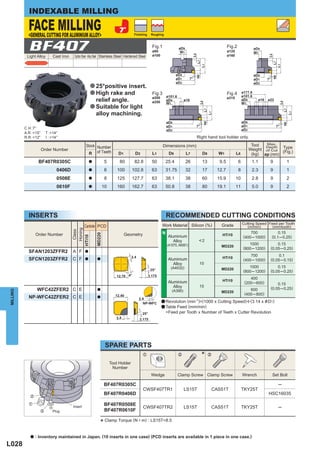

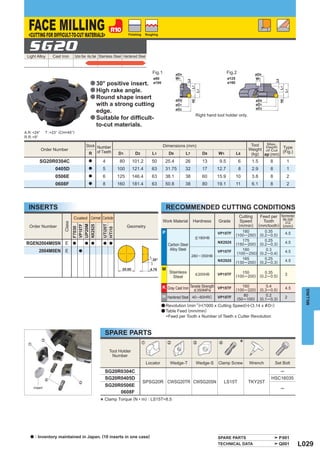

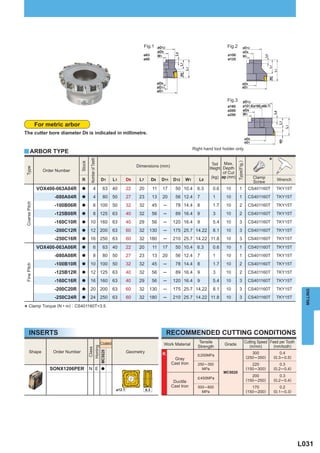

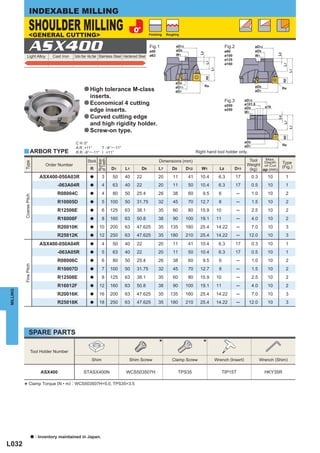

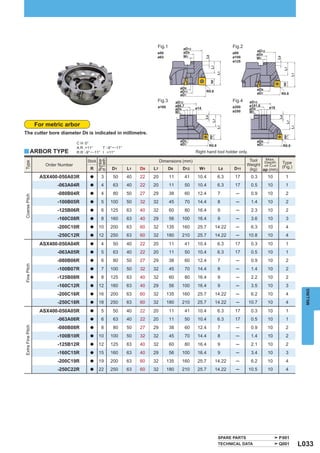

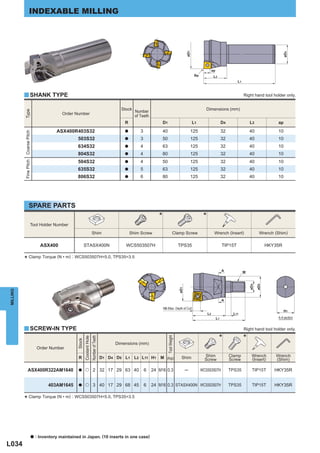

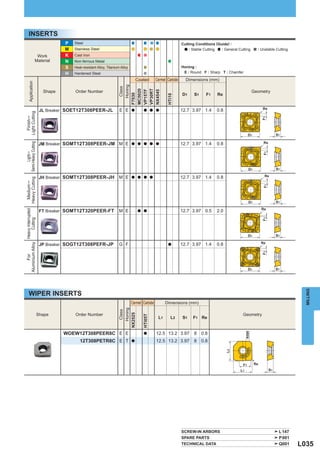

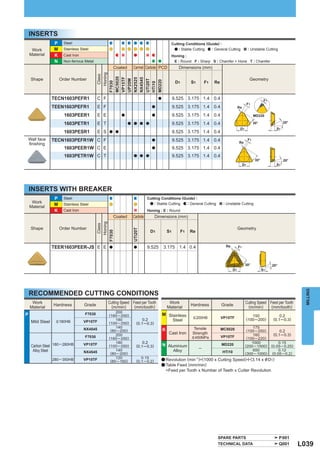

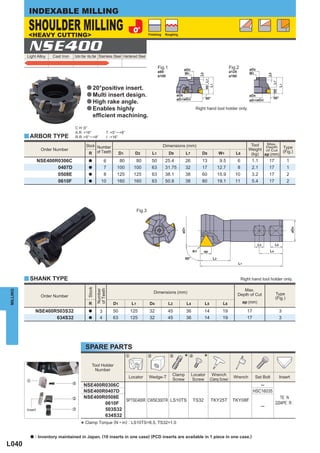

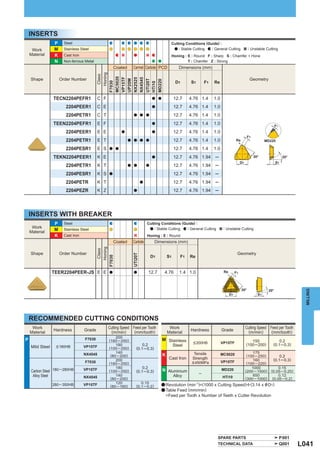

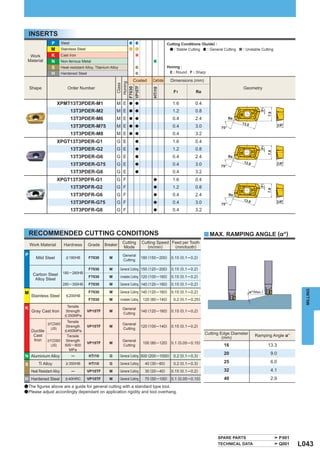

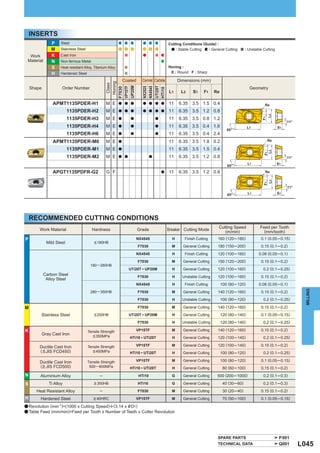

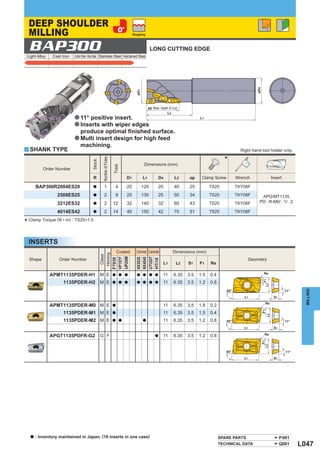

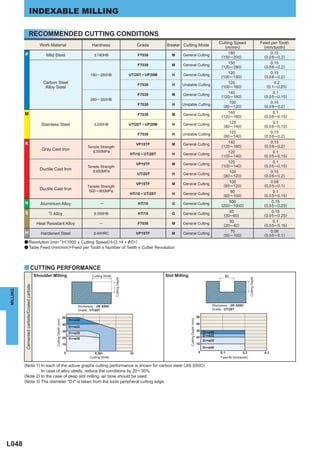

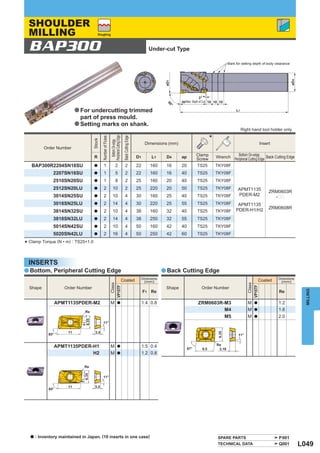

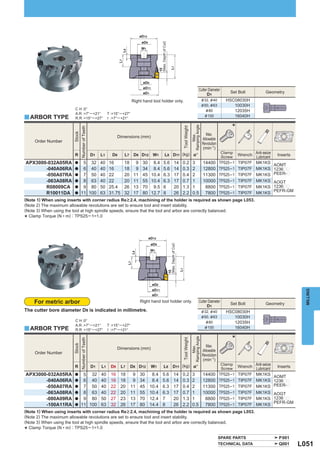

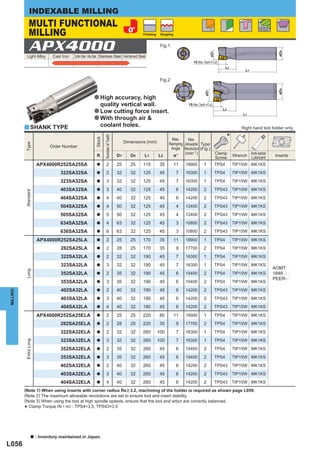

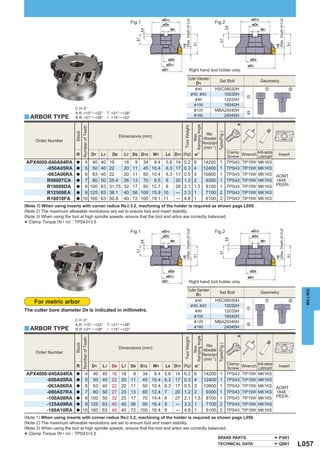

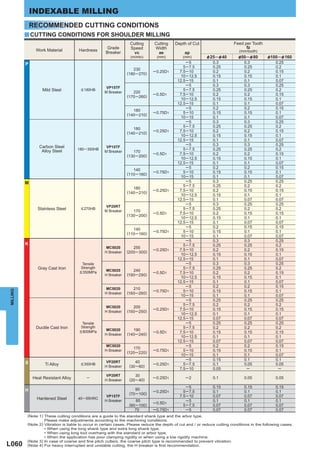

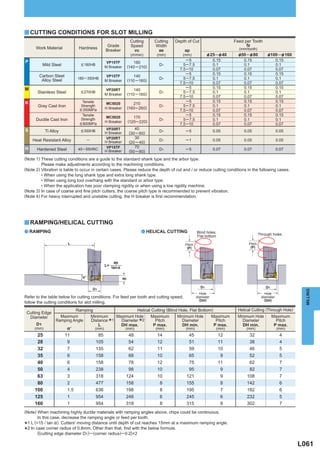

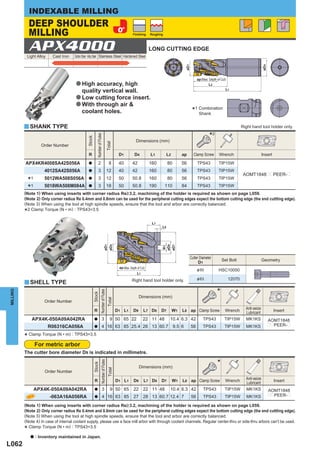

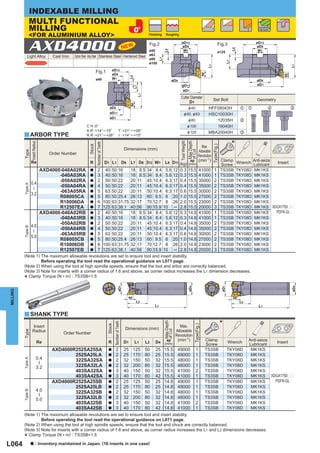

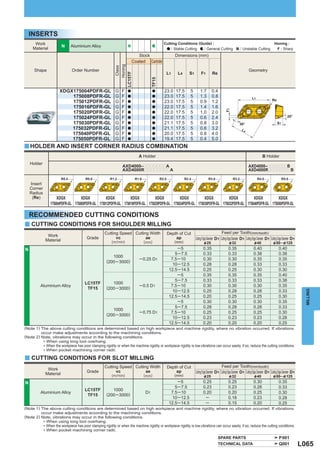

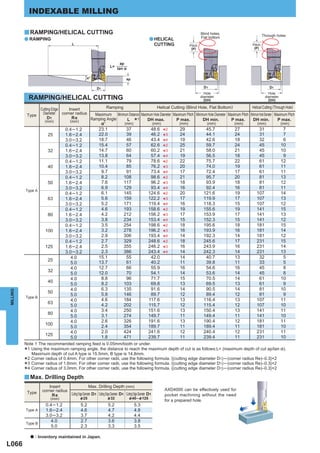

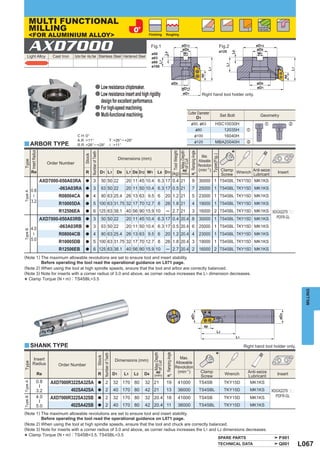

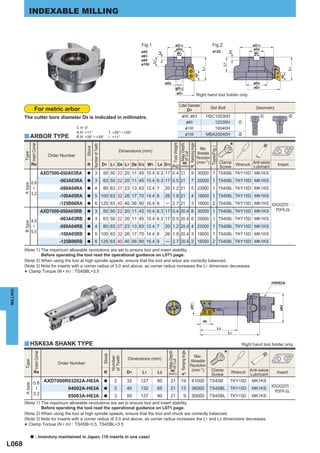

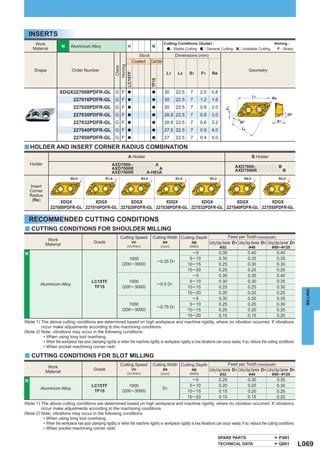

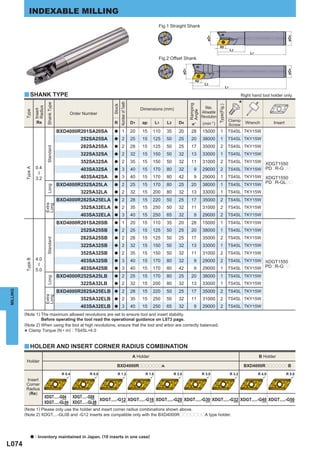

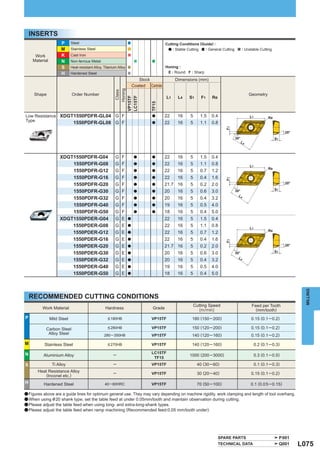

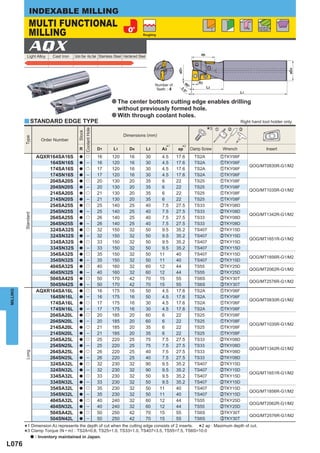

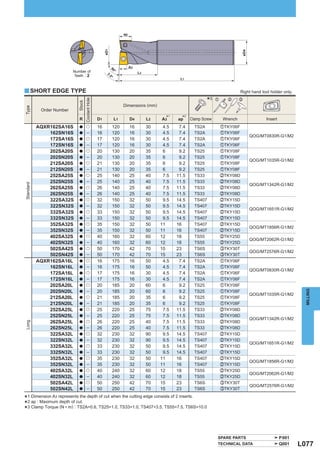

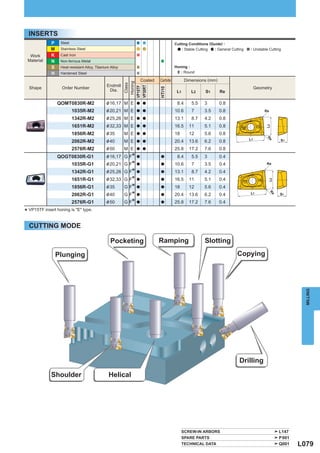

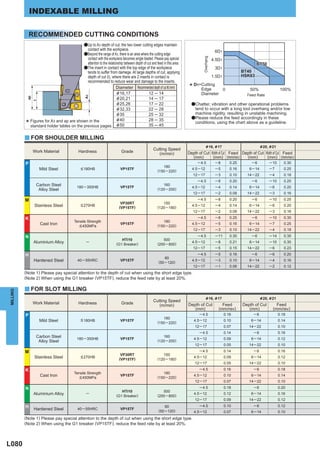

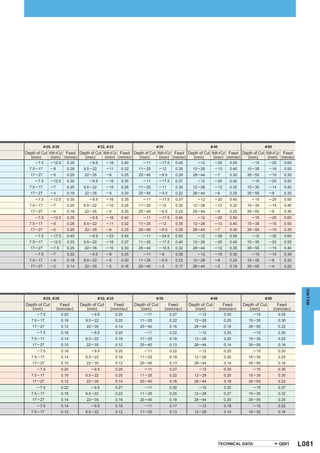

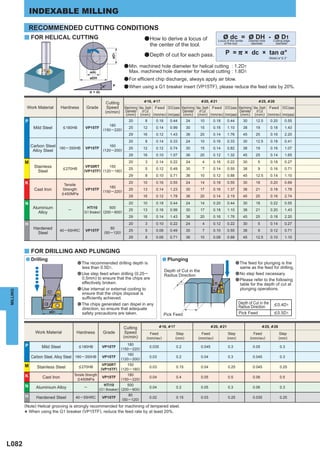

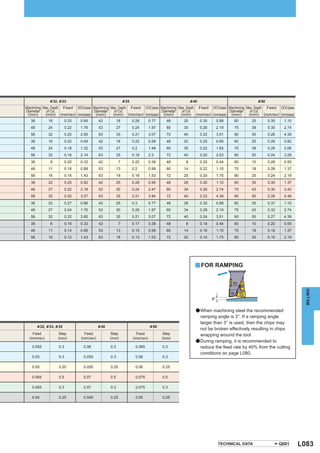

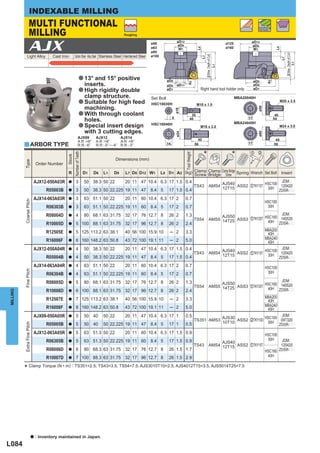

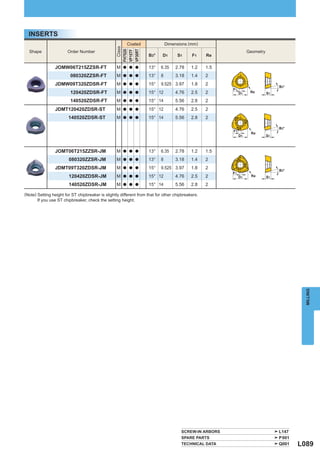

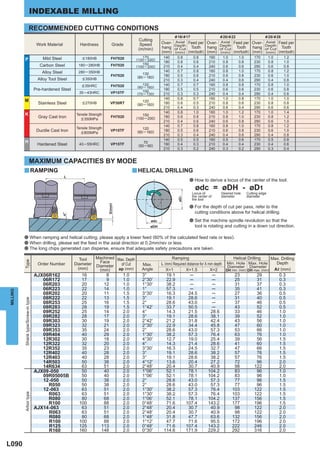

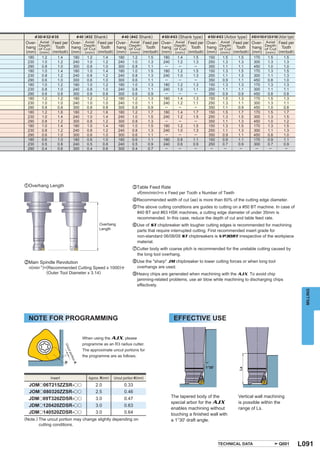

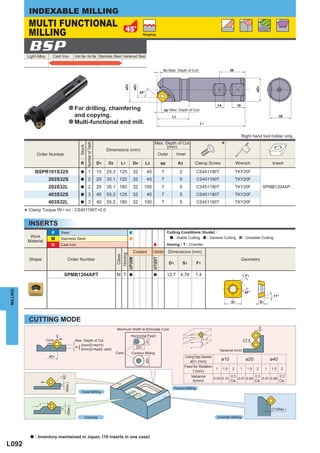

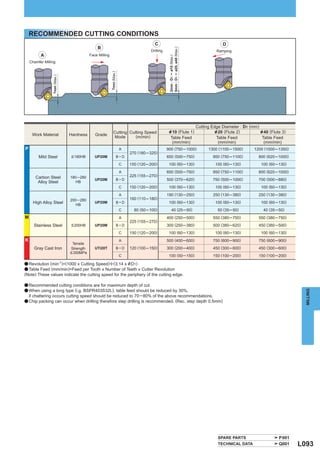

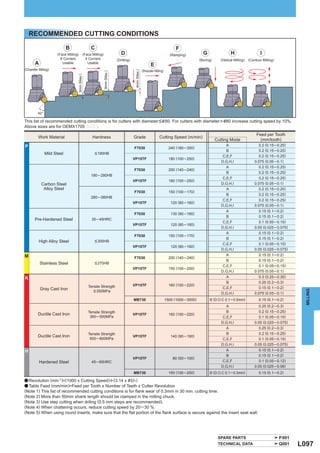

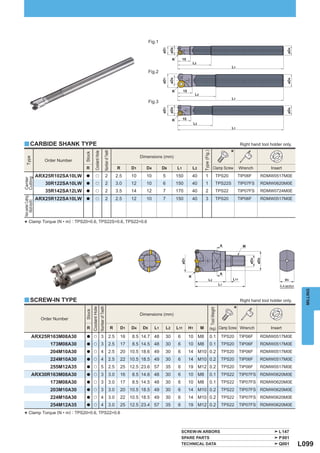

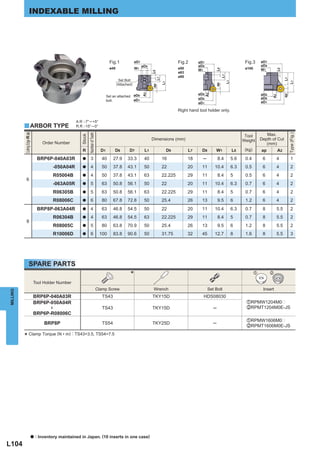

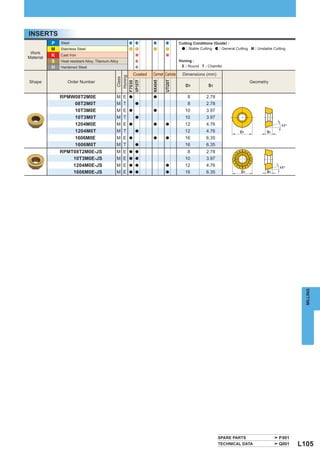

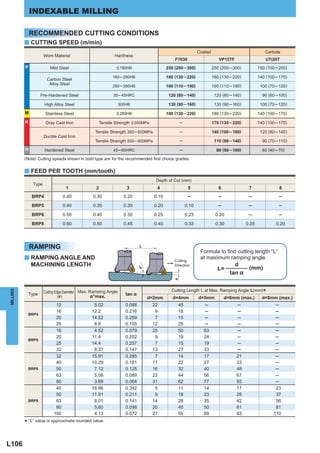

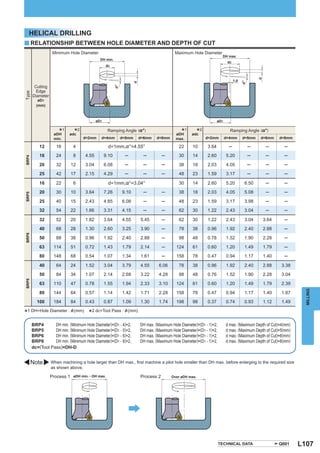

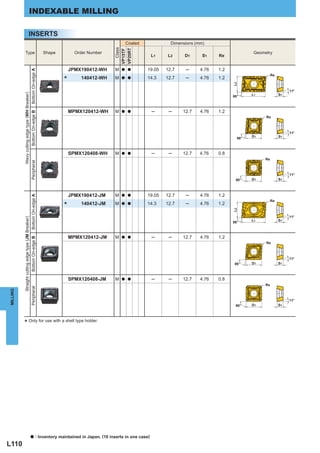

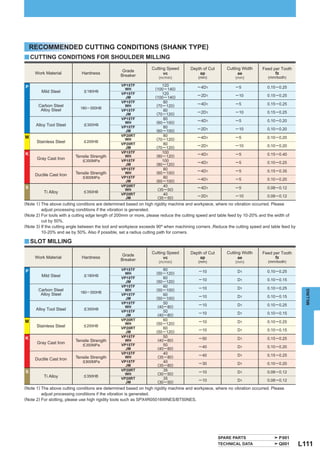

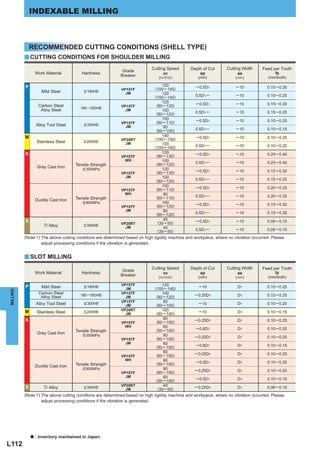

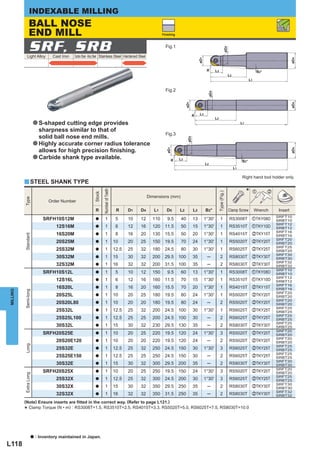

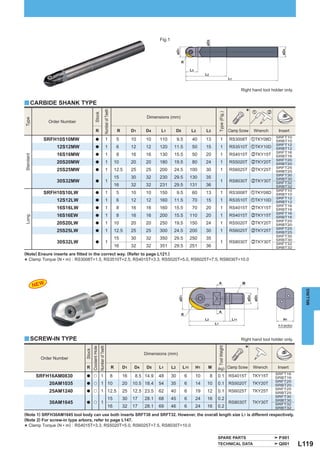

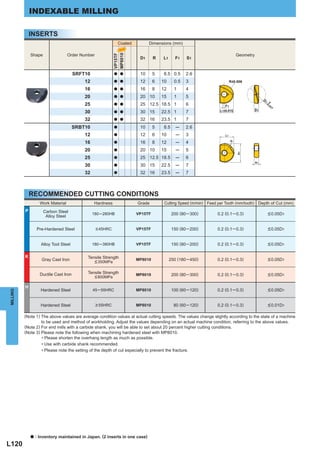

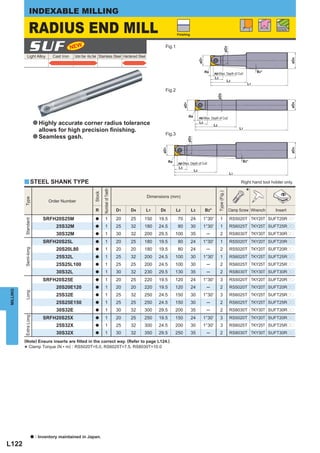

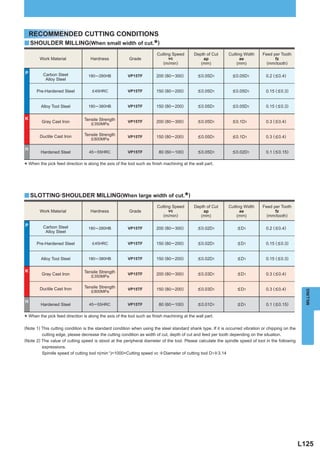

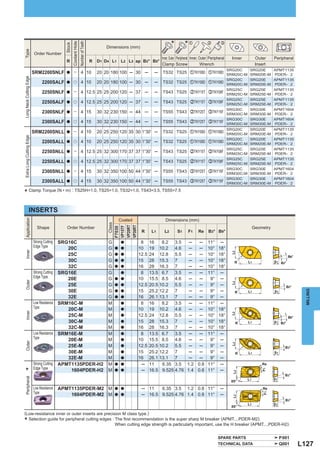

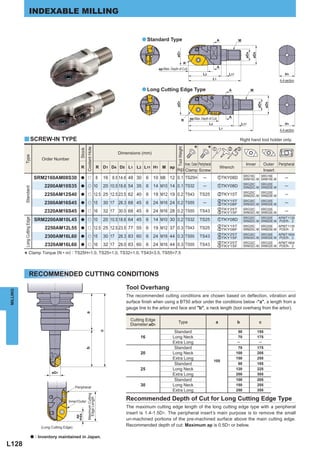

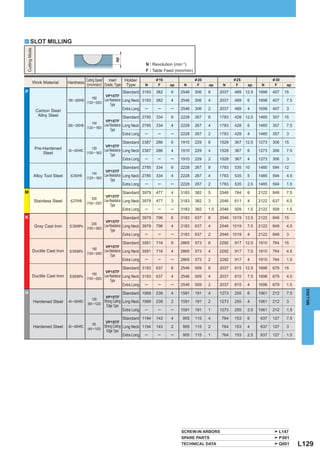

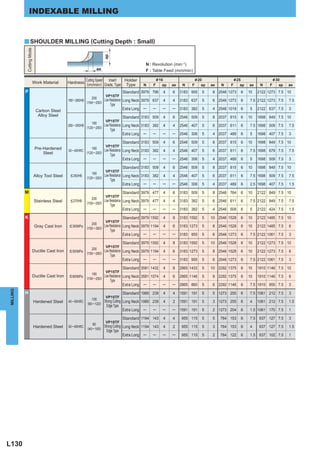

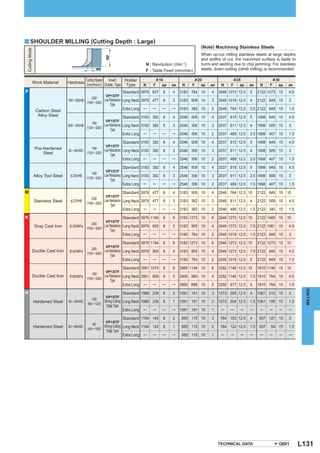

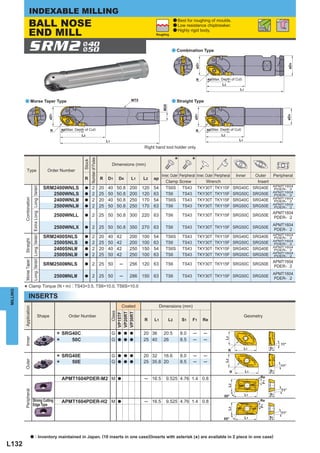

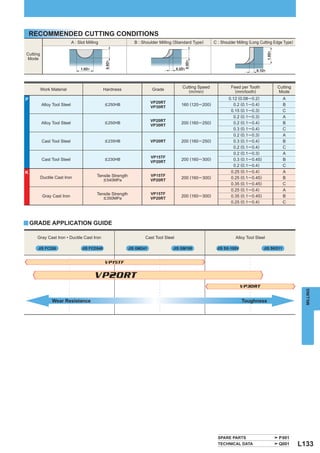

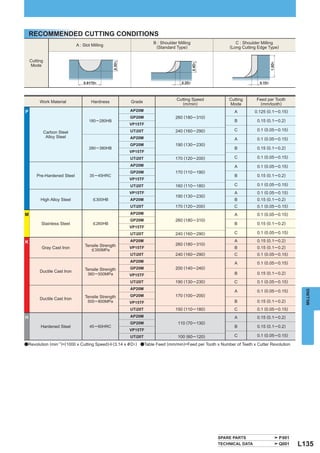

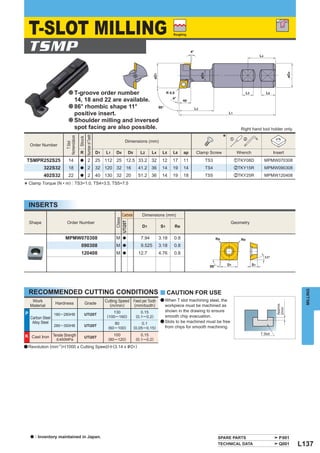

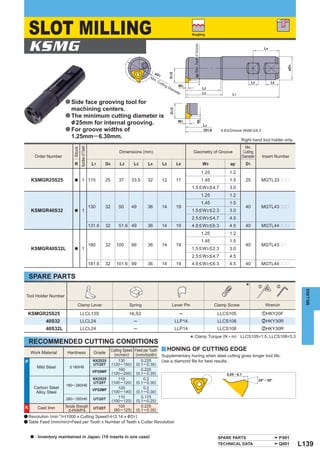

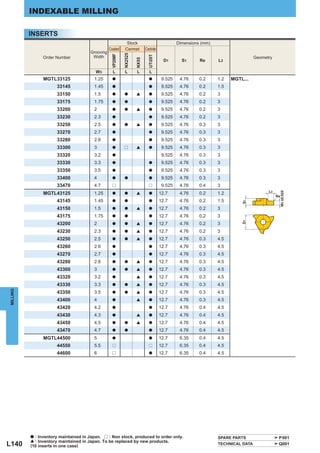

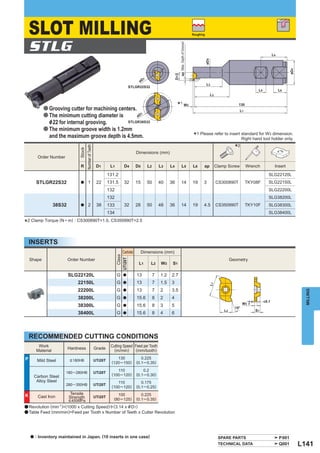

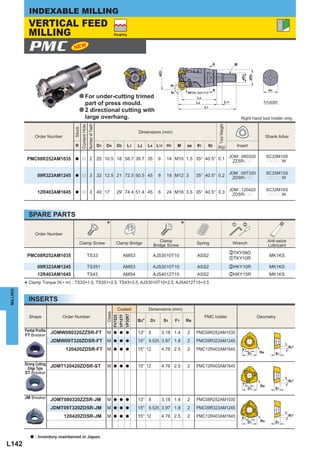

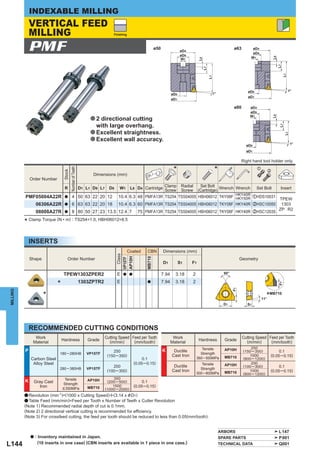

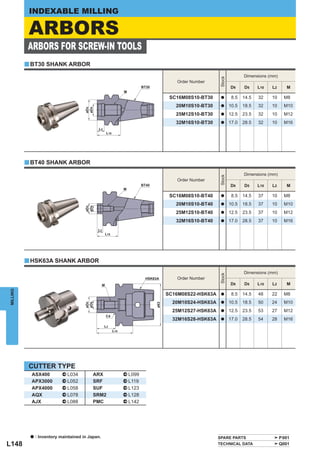

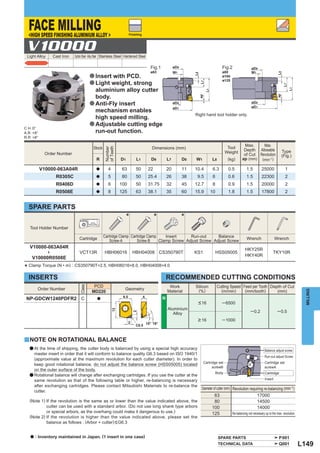

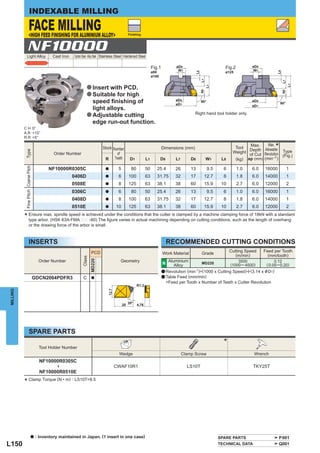

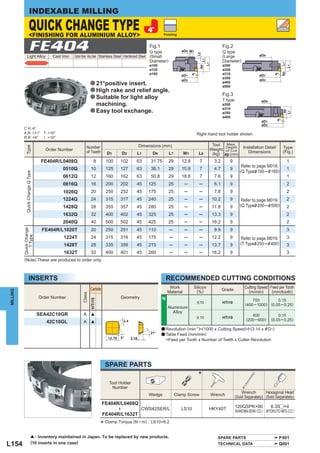

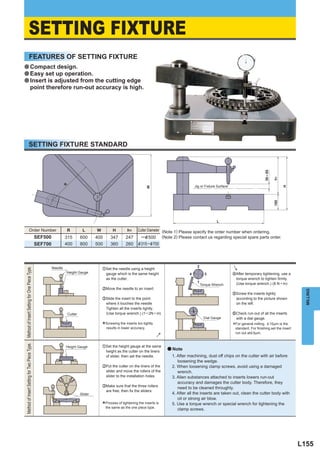

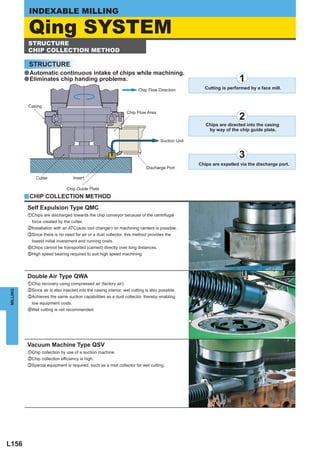

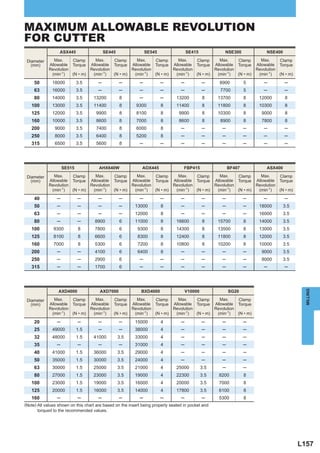

This document provides information on indexable milling, specifically face milling cutting modes. It is organized by cutting mode and lists specifications for various milling cutters, including dimensions, material compatibility, and applications. Product names, order numbers, and technical details like tooth count, shank size, and maximum cutting depths are provided for each cutter.