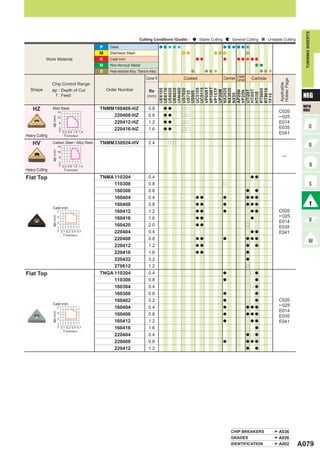

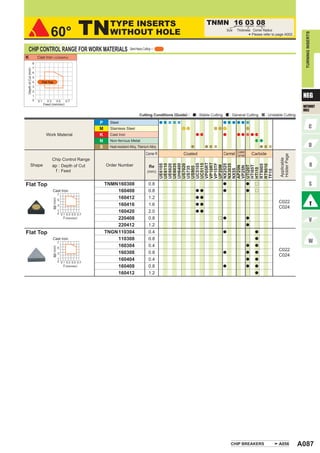

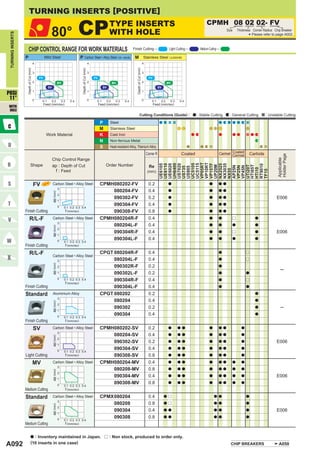

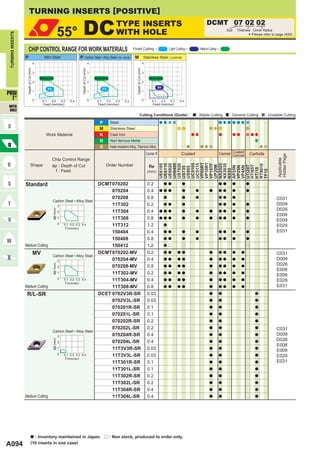

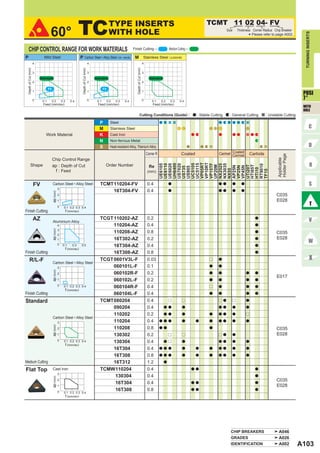

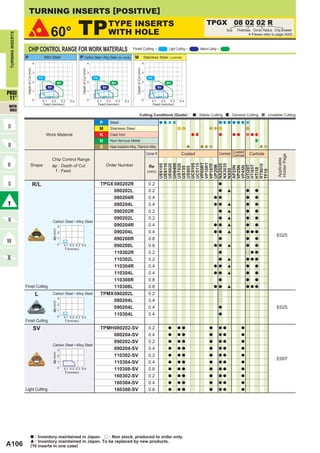

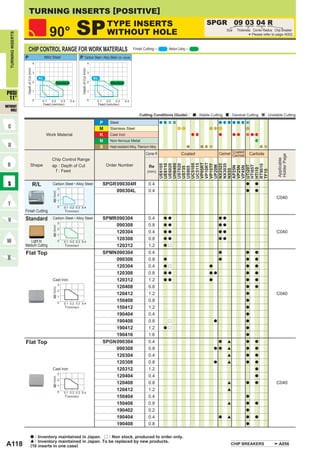

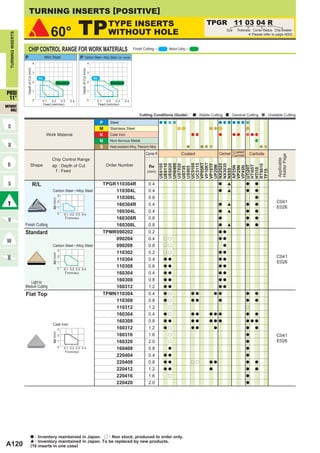

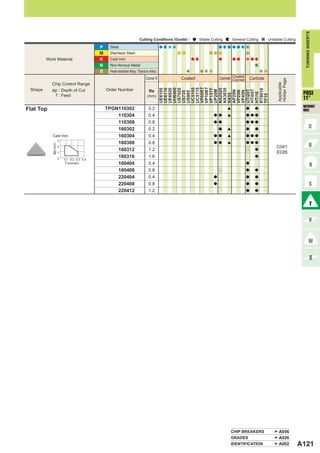

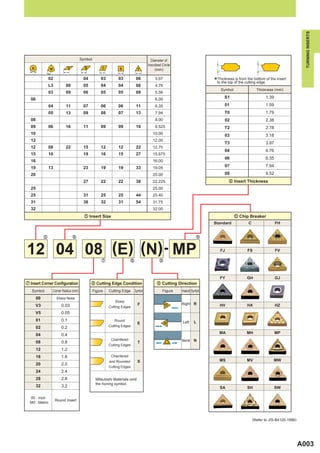

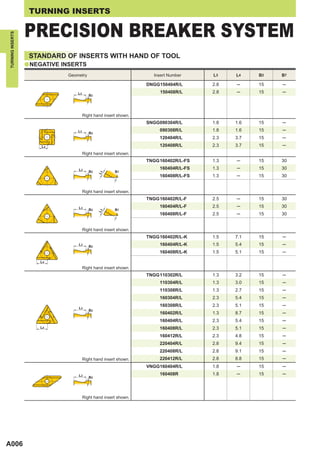

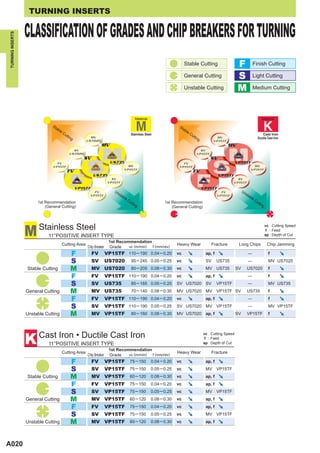

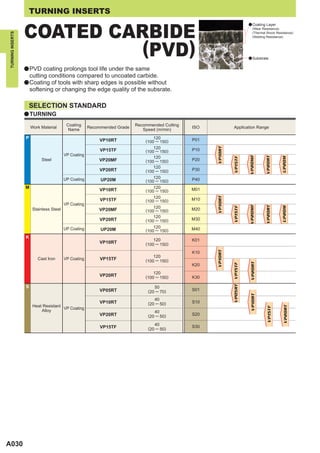

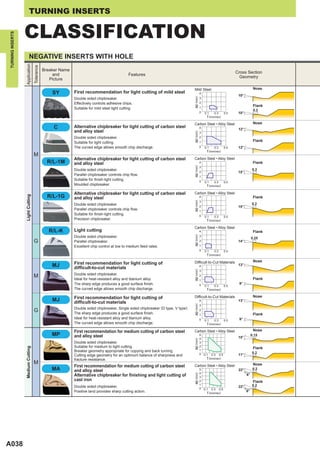

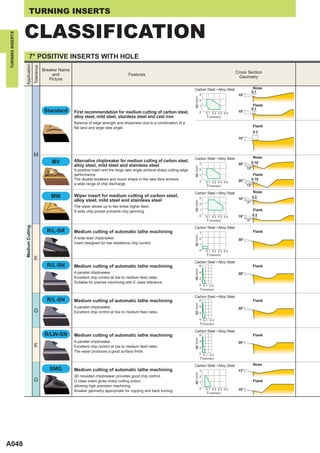

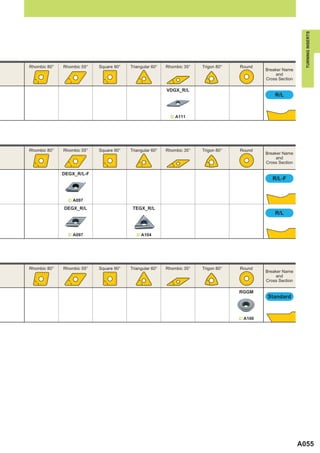

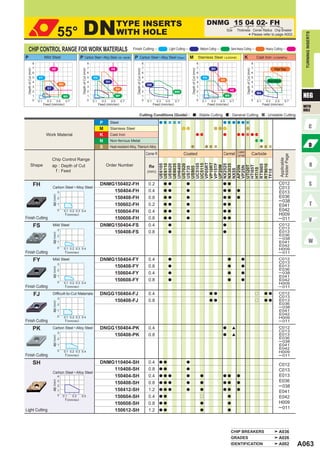

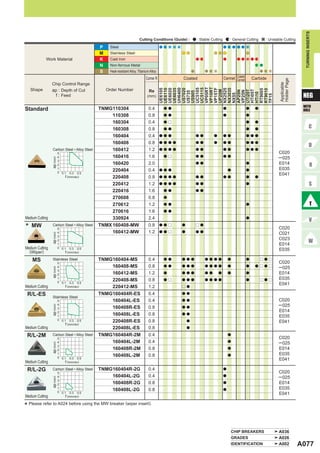

This document provides information on how to read turning insert standards. It is organized by insert shape and includes details like grade, application, recommended work materials, and cutting conditions. Graphs show recommended chip breakers and cutting ranges for different materials and applications, from finish to heavy cutting. Inserts are shown in order of negative or positive type, with breakers arranged from finish to heavy cutting. Specifications for individual inserts include size, grade, recommended uses and cutting conditions.

![HOW TO READ THE STANDARD

OF TURNING INSERTS

a How this section page is organized a Graph of chip control by work material

z Organized according to turning insert shape. Shows recommended chip breakers and chip control range

(Refer to the index on the next page.) according to work material and cutting application.

x Inserts are arranged in order of : Graphs are colored according to cutting applications

• Negative inserts (with hole|without hole) (Finish|Light|Medium|Semi-Heavy|Heavy)

• Positive inserts (with hole|without hole) and contain recommended breakers for each application.

c Breakers are arranged in order of :

Finish Cutting|Light Cutting|Medium Cutting Finish Cutting : Light Cutting : Medium Cutting :

|Semi-Heavy Cutting|Heavy Cutting Semi-Heavy Cutting : Heavy Cutting :

GRADE APPLICATION RECOMMENDED

FOR EACH WORK MATERIAL

cutting conditions suitable for each type of work material

is shown as a general guide to select the grade.

: Stable Cutting : General Cutting : Unstable Cutting

SHAPE & ANGLE INDICATION OF NEGATIVE/ STOCK STATUS

MARK POSITIVE TYPE

TITLE OF PRODUCT INSERT GRADES

PRODUCT ACCORDING TO THE INSERT

SECTION INSERT TYPE NUMBER

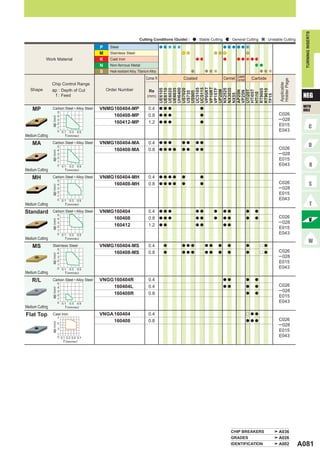

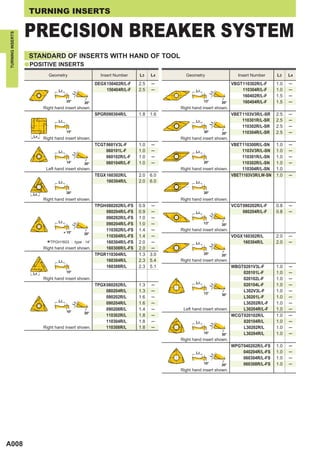

TURNING INSERTS [NEGATIVE]

80° CN TYPE INSERTS

WITH HOLE

CNMG 12 04 02- FH

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

TURNING INSERTS

Please refer to page A002.

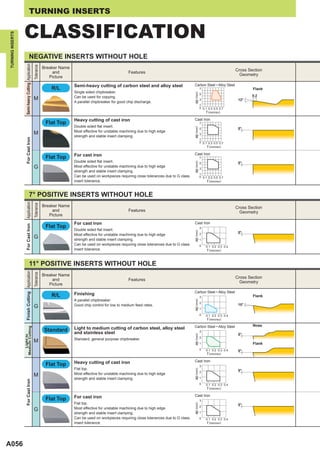

* Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

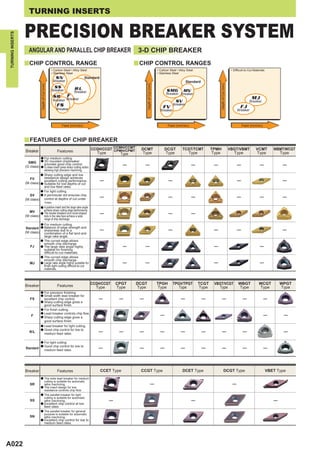

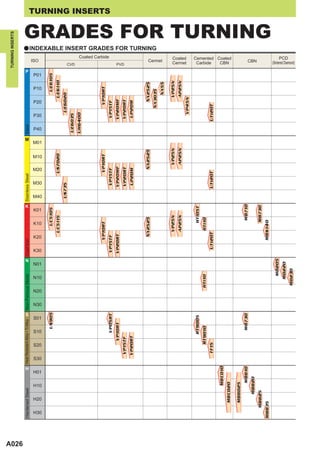

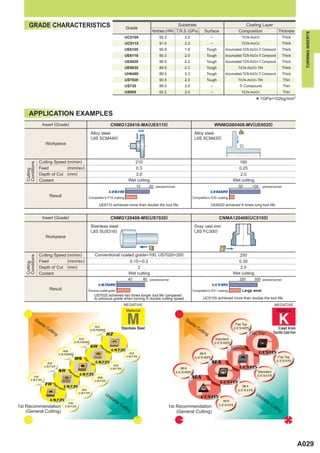

P Steel

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

M Stainless Steel

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

Work Material K Cast Iron

8 8 8 8 8

7 7 7 7 7

N Non-ferrous Metal

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

SH

Depth of Cut (mm)

HZ HX Flat Top

6 6 6 6 6 S Heat-resistant Alloy, Titanium Alloy

5 5 5 5 5 Coated

FY FH FH Corner R Coated Cermet Cermet Carbide

Holder Page

GH Standard

4 4 SH 4 4 4

Applicable

MH SW Chip Control Range

3 3 3 3 3

VP05RT

VP10RT

SY

UH6400

UC5105

UC5115

VP15TF

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

GH Shape ap : Depth of Cut Order Number

UP20M

HTi05T

UTi20T

HZ Re

AP25N

VP25N

US735

US905

2 2 2 MW 2 2

HTi10

MA

NX55

NEG NEG

TF15

1 MS 1 MP 1 1 MS 1 f : Feed (mm)

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH WITH

SA Carbon Steel • Alloy Steel CNMG120404-SA 0.4 a a a a C010

HOLE 4

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting 120408-SA 0.8 a a a a C011

ap (mm)

3

E013

P Steel 2 120412-SA 1.2 a a a a

1 E042

M Stainless Steel

0

160608-SA 0.8 r H006

0.1 0.3 0.5

Work Material K Cast Iron Light Cutting f (mm/rev) 160612-SA 1.2 a r ─ 008

N Non-ferrous Metal

CNMG120404-SW 0.4 a a a a a a

* SW Carbon Steel • Alloy Steel C010

S Heat-resistant Alloy, Titanium Alloy 4

a a a a a a C011

120408-SW 0.8

ap (mm)

Coated 3

Corner R Coated Cermet Cermet Carbide E013

Holder Page

2 120412-SW 1.2 a a a a a

E042

Applicable

Chip Control Range 1

VP05RT

VP10RT

H006

UH6400

UC5105

UC5115

VP15TF

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Shape ap : Depth of Cut Order Number Light Cutting

UP20M

HTi05T

0

UTi20T

Re

AP25N

VP25N

0.1 0.3 0.5

US735

US905

HTi10

(Wiper) ─ 008

NX55

f (mm/rev)

TF15

f : Feed (mm)

SY Mild Steel CNMG120404-SY 0.4 a a a C010

4

FH Carbon Steel • Alloy Steel CNMG120402-FH 0.2 a a a a a C010 120408-SY 0.8 a a a C011

ap (mm)

3

3 C011 E013

120404-FH 0.4 a a a a a a 2

ap (mm)

2 E013 1 E042

120408-FH 0.8 a a a a a a H006

1 E042 0 0.1 0.3 0.5

120412-FH 1.2 a a H006 Light Cutting f (mm/rev) ─ 008

0 0.1 0.2 0.3 0.4

Finish Cutting f (mm/rev) ─ 008 C Carbon Steel • Alloy Steel CNMG120404-C 0.4 [[ C010

4

FS Mild Steel CNMG120404-FS 0.4 a a C010 120408-C 0.8 [[ C011

ap (mm)

3

3 C011 E013

120408-FS 0.8 a a 2

ap (mm)

2 E013 1 E042

1 E042 0 0.1 0.3 0.5

H006

H006 Light Cutting f (mm/rev) ─ 008

0 0.1 0.2 0.3 0.4

Finish Cutting f (mm/rev) ─ 008 MJ Difficult-to-Cut Materials CNMG120404-MJ 0.4 a a a r a C010

4

Mild Steel CNMG120404-FY a a a 120408-MJ 0.8 a a a r a C011

FY 0.4 C010

ap (mm)

3

3

C011 E013

120408-FY 0.8 a a a 2 120412-MJ 1.2 a a a

ap (mm)

2 E013 1 E042

120416-MJ 1.6 a a a H006

1 E042 0 0.1 0.3 0.5

H006 Light Cutting f (mm/rev) ─ 008

0 0.1 0.2 0.3 0.4

Finish Cutting f (mm/rev) ─ 008 MJ Difficult-to-Cut Materials CNGG 120404-MJ 0.4 r a a a a a C010

4

CNGG 1204V5-FJ a a 120408-MJ 0.8 r a a a a a C011

FJ Difficult-to-Cut Materials 0.05 C010

ap (mm)

3

3

C011 E013

120401-FJ 0.1 a a 2

ap (mm)

2 E013 1 E042

120402-FJ 0.2 a a H006

1 E042 0 0.1 0.3 0.5

120404-FJ 0.4 a a r a a H006 Light Cutting f (mm/rev) ─ 008

0 0.1 0.2 0.3 0.4

Finish Cutting f (mm/rev) 120408-FJ 0.8 a a r a a ─ 008 MP CNMG120404-MP 0.4 a a a a

Carbon Steel • Alloy Steel CNGG 120404-PK a [ Carbon Steel • Alloy Steel 120408-MP 0.8 a a a a C010

PK 0.4 C010

5

3

120408-PK 0.8 a [ C011 4 120412-MP 1.2 a a a a C011

ap (mm)

ap (mm)

2 E013 3 E013

2 120416-MP 1.6 a a a a

1 E042 1

E042

160608-MP 0.8 a a a a H006

0 0.1 0.2 0.3 0.4 H006 0 0.1 0.3 0.5

Finish Cutting f (mm/rev) ─ 008 f (mm/rev) 160612-MP 1.2 a a a a ─ 008

CNMG090304-SH r Medium Cutting 160616-MP 1.6 a a a a

SH 0.4

Carbon Steel • Alloy Steel 090308-SH 0.8 r C010 MA CNMG120404-MA 0.4 a a a a a a a a a a

4

09T304-SH 0.4 a a C011 120408-MA 0.8 a a a a a a a a a a

ap (mm)

3

E013 a a a a a a a a a a

2 09T308-SH 0.8 a a Carbon Steel • Alloy Steel 120412-MA 1.2 C010

1 E042 5

120404-SH 0.4 a a a a a a a a 4 120416-MA 1.6 a a a a a a a a C011

H006

ap (mm)

0 0.1 0.3 0.5 3 E013

f (mm/rev) 120408-SH 0.8 a a a a a a a a ─ 008 2 160608-MA 0.8 a a a a r a a

1

E042

Light Cutting 120412-SH 1.2 a a a r a a a 160612-MA 1.2 a a a a a a a a H006

0 0.1 0.3 0.5

f (mm/rev) 160616-MA 1.6 a a a r a a a ─ 008

190612-MA 1.2 a a a a a a a a

Medium Cutting 190616-MA 1.6 a a a r a a a

* Please refer to A024 before using the SW breaker (wiper insert).

CHIP BREAKERS A036

a : Inventory maintained in Japan. r : Non stock, produced to order only. GRADES A026

[ : Inventory maintained in Japan. To be replaced by new products.

A058 (10 inserts in one case) IDENTIFICATION A002 A059

LEGEND FOR STOCK STATUS MARK

is shown on the left hand page of PAGE REFERENCE

each double-page spread. ·CHIP BREAKERS

CUTTING APPLICATION ·GRADES

is shown in order of: Finish|Light ·TECHNICAL DATA

|Medium|Semi-Heavy|Heavy. indicates reference pages, on the right hand page of

each double-page spread.

PHOTO OF INSERT

INDICATION OF CHIPBREAKER APPLICABLE HOLDER PAGE

indicates the designation indicates reference pages for details of applicable holders.

for a chipbreaker.

INSERT CORNER RADIUS

a To Order : Please specify

zinsert number and xgrade.

A000](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/75/TURNING-INSERTS-1-2048.jpg)

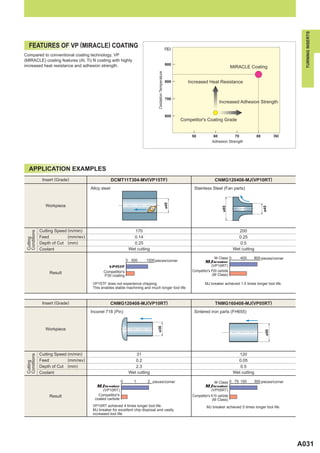

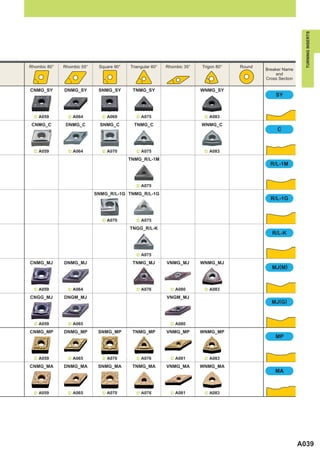

![TURNING INSERTS [NEGATIVE]

80° CN TYPE INSERTS

WITH HOLE

CNMG 12 04 02- FH

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

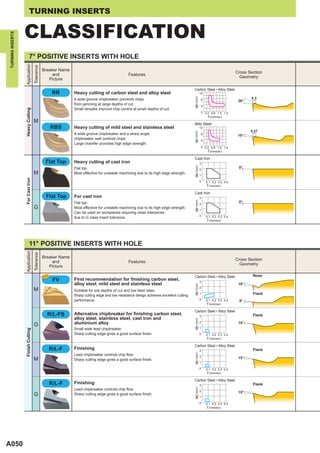

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8 8

7 HZ 7 HX 7 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6 6

5 FY 5 FH 5 5 FH 5

GH Standard

4 4 SH 4 4 4

MH SW

3 3 3 3 3

SY GH

2 2 2 2 HZ 2

MW

NEG

MA

1 MS 1 MP 1 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

FH Carbon Steel • Alloy Steel CNMG120402-FH 0.2 a a a a a C010

3

120404-FH 0.4 a a a a a a C011

ap (mm)

2 E013

120408-FH 0.8 a a a a a a

1 E042

0

120412-FH 1.2 a a H006

0.1 0.2 0.3 0.4

Finish Cutting f (mm/rev) ─ 008

FS Mild Steel CNMG120404-FS 0.4 a a C010

3

120408-FS 0.8 a a C011

ap (mm)

2 E013

1 E042

0 0.1 0.2 0.3 0.4 H006

Finish Cutting f (mm/rev) ─ 008

FY Mild Steel CNMG120404-FY 0.4 a a a C010

3

120408-FY 0.8 a a a C011

ap (mm)

2 E013

1 E042

0 0.1 0.2 0.3 0.4 H006

Finish Cutting f (mm/rev) ─ 008

FJ Difficult-to-Cut Materials CNGG 1204V5-FJ 0.05 a a C010

3

120401-FJ 0.1 a a C011

ap (mm)

2 E013

120402-FJ 0.2 a a

1 E042

0 0.1 0.2 0.3 0.4

120404-FJ 0.4 a a r a a H006

Finish Cutting f (mm/rev) 120408-FJ 0.8 a a r a a ─ 008

PK Carbon Steel • Alloy Steel CNGG 120404-PK 0.4 a [ C010

3

120408-PK 0.8 a [ C011

ap (mm)

2 E013

1 E042

0 0.1 0.2 0.3 0.4 H006

Finish Cutting f (mm/rev) ─ 008

SH CNMG090304-SH 0.4 r

Carbon Steel • Alloy Steel 090308-SH 0.8 r C010

4

09T304-SH 0.4 a a C011

ap (mm)

3

E013

2 09T308-SH 0.8 a a

1 E042

0 0.1 0.3 0.5

120404-SH 0.4 a a a a a a a a H006

f (mm/rev) 120408-SH 0.8 a a a a a a a a ─ 008

Light Cutting 120412-SH 1.2 a a a r a a a

a : Inventory maintained in Japan. r : Non stock, produced to order only.

[ : Inventory maintained in Japan. To be replaced by new products.

A058 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-59-320.jpg)

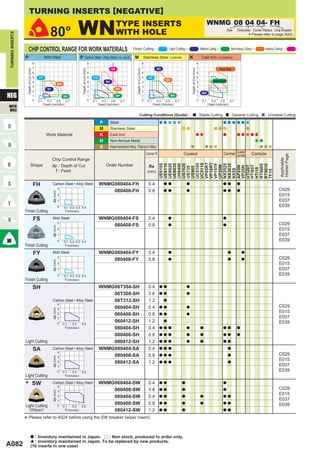

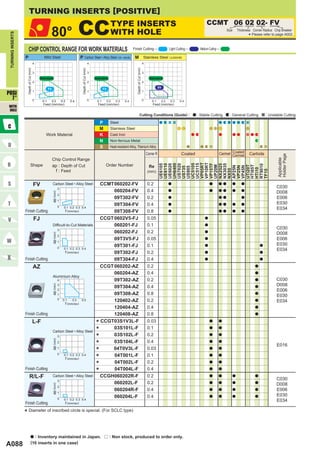

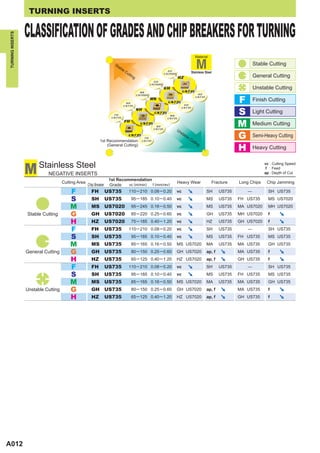

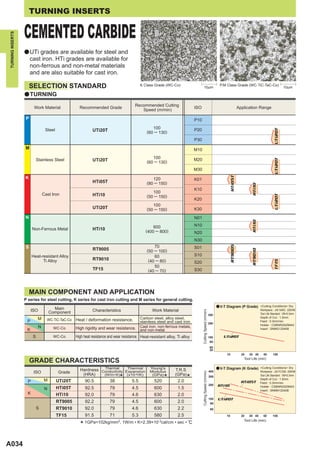

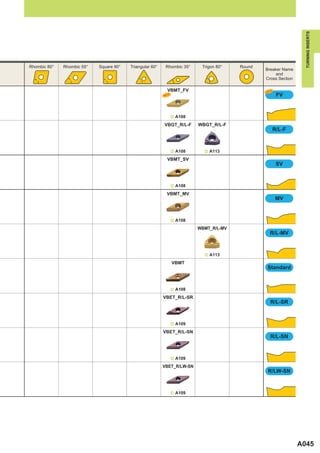

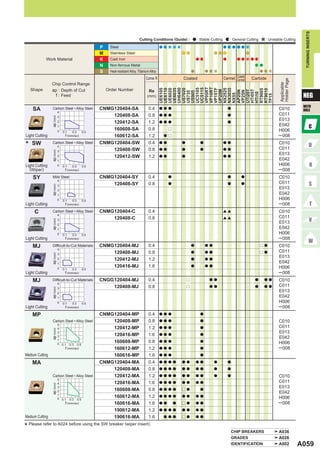

![TURNING INSERTS [NEGATIVE]

80° CN TYPE INSERTS

WITH HOLE

CNMG 12 04 04- MH

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

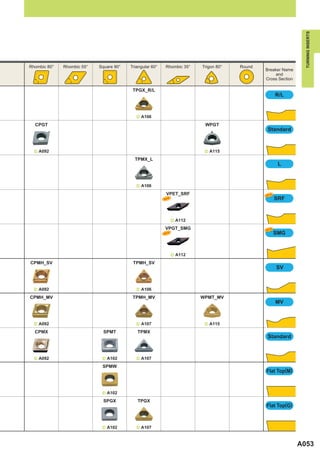

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8 8

7 HZ 7 HX 7 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6 6

5 FY 5 FH 5 5 FH 5

GH Standard

4 4 SH 4 4 4

MH SW

3 3 3 3 3

SY GH

2 2 2 2 HZ 2

MW

NEG

MA

1 MS 1 MP 1 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

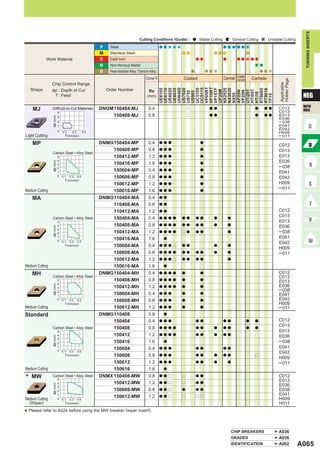

MH CNMG120404-MH 0.4 a a a a a a

120408-MH 0.8 a a a a a a

Carbon Steel • Alloy Steel 120412-MH 1.2 a a a a a a C010

5

4 120416-MH 1.6 a a a a a C011

ap (mm)

3 E013

2 160608-MH 0.8 a a a

1

E042

0 0.1

160612-MH 1.2 a a a a a a H006

0.3 0.5

f (mm/rev) 160616-MH 1.6 a a a ─ 008

190612-MH 1.2 a a a a a a

Medium Cutting 190616-MH 1.6 a a a a

Standard CNMG090308 0.8 a

09T304 0.4 a a

09T308 0.8 a a

120404 0.4 a a a a a a a a a a

120408 0.8 a a a a a a a a a a a

Carbon Steel • Alloy Steel C010

5 120412 1.2 a a a a a a a a a a r

C011

4

ap (mm)

3 120416 1.6 a a r a a E013

2

1 160608 0.8 a a a r E042

0 0.1 H006

0.3 0.5 160612 1.2 a a a a a a a

f (mm/rev) ─ 008

160616 1.6 a a a a a a

190608 0.8 a a a a

190612 1.2 a a a a a a a

190616 1.6 a a a a a a

Medium Cutting 190624 2.4 r

* MW Carbon Steel • Alloy Steel

5

CNMG120408-MW 0.8 a a a a a a C010

C011

4 120412-MW 1.2 a a a a a a

ap (mm)

3 E013

2

1

E042

Medium Cutting 0 0.1 0.3 0.5 H006

(Wiper) f (mm/rev) ─ 008

MS CNMG090304-MS 0.4 r a

090308-MS 0.8 a r a

Stainless Steel C010

5 09T304-MS 0.4 r a r a

C011

4

ap (mm)

3 09T308-MS 0.8 a r a r a E013

2

1 120404-MS 0.4 a a a a a a a a a a a a r a a E042

0 0.1 H006

0.3 0.5 120408-MS 0.8 a a a a a a a a a a a a r a a

f (mm/rev) ─ 008

120412-MS 1.2 a r a a a a a a a a a r a a

Medium Cutting 120416-MS 1.6 a r r

* Please refer to A024 before using the MW :breaker (wiper insert). to order only.

a : Inventory maintained in Japan. r Non stock, produced

A060 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-61-320.jpg)

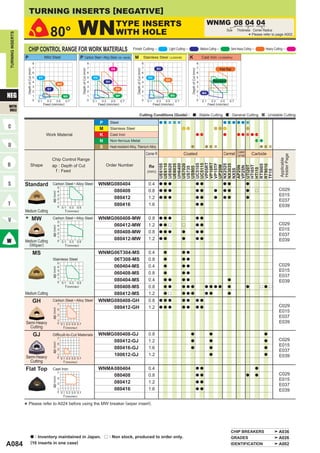

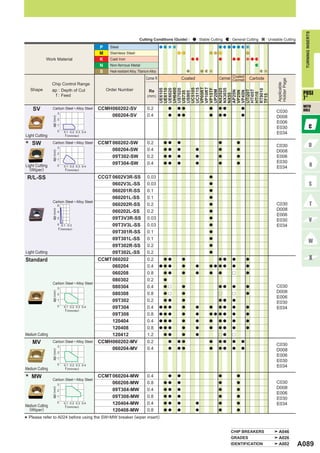

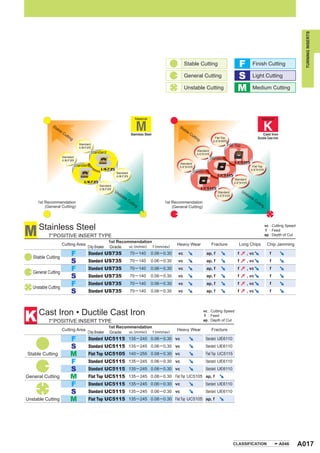

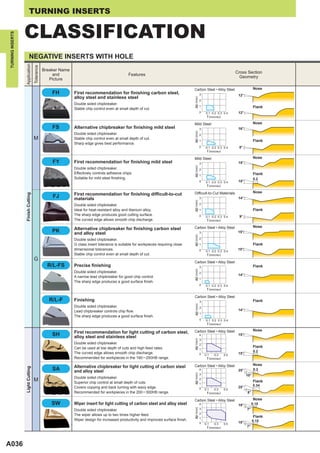

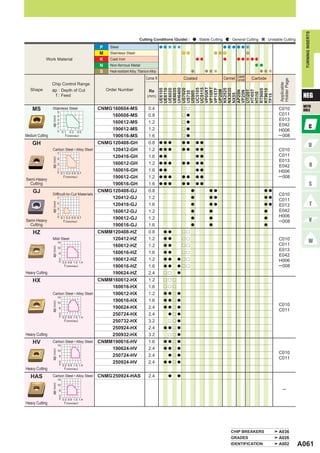

![TURNING INSERTS [NEGATIVE]

80° CN TYPE INSERTS

WITH HOLE

CNMM 19 06 12- HXD

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

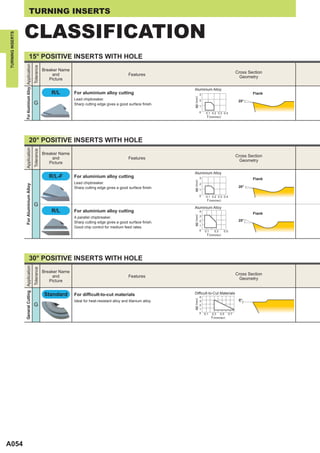

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8 8

7 HZ 7 HX 7 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6 6

5 FY 5 FH 5 5 FH 5

GH Standard

4 4 SH 4 4 4

MH SW

3 3 3 3 3

SY GH

2 2 2 2 HZ 2

MW

NEG

MA

1 MS 1 MP 1 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

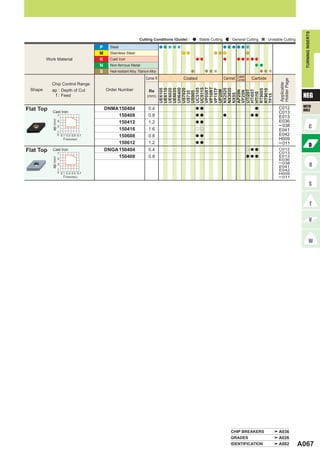

HXD Mild Steel

14

CNMM190612-HXD 1.2 a a

190616-HXD 1.6 a a

ap (mm)

10

C010

6 190624-HXD 2.4 a a

C011

2

0 0.2 0.6 1.0 1.4

250924-HXD 2.4 a a

Heavy Cutting f (mm/rev)

Flat Top CNMA 120404 0.4 a a a a

120408 0.8 a a a a a

Cast Iron C010

7 120412 1.2 a a r a a

C011

ap (mm)

5

120416 1.6 a a E013

3

160612 1.2 a a E042

1

0 0.1 0.3 0.5 0.7 H006

160616 1.6 a a

f (mm/rev) ─ 008

190612 1.2 a a a

190616 1.6 a a

a : Inventory maintained in Japan. r : Non stock, produced to order only.

[ : Inventory maintained in Japan. To be replaced by new products.

A062 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-63-320.jpg)

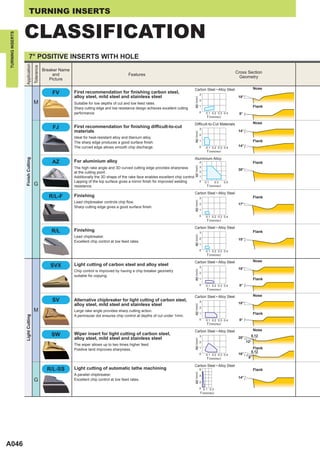

![TURNING INSERTS [NEGATIVE]

55° DN TYPE INSERTS

WITH HOLE

DNMG 15 04 04- SA

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8 8

7 HZ 7 HX 7 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6 6

5 FY 5 FH 5 5 FH 5

GH Standard

4 4 SH 4 4 4

MH SW

3 3 3 3 3

SY GH

2 2 2 2 HZ 2

MW

NEG

MA

1 MS 1 MP 1 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

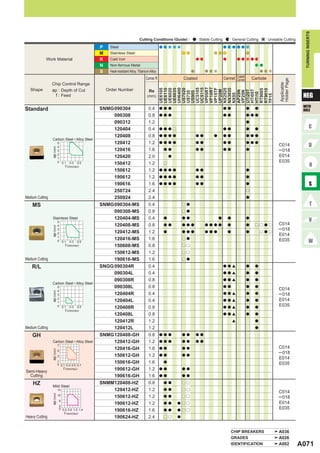

SA DNMG150404-SA 0.4 a a a a C012

Carbon Steel • Alloy Steel C013

4 150408-SA 0.8 a a a a

E013

E036

ap (mm)

3

150412-SA 1.2 a a a a

2 ─ 038

1 150604-SA 0.4 a a a a E041

0 0.1 0.3 0.5 150608-SA 0.8 a a a a E042

f (mm/rev) H009

Light Cutting 150612-SA 1.2 a a a a ─ 011

* SW DNMX 110404-SW 0.4 a

110408-SW 0.8 a C012

Carbon Steel • Alloy Steel

4 150404-SW 0.4 a a a a a E013

E036

ap (mm)

3

150408-SW 0.8 a a a a a

2 E038

1 150412-SW 1.2 a a a a a

E041

0 0.1 0.3 0.5 150604-SW 0.4 a a a a a H009

f (mm/rev)

150608-SW 0.8 a a a a a H011

Light Cutting

(Wiper) 150612-SW 1.2 a a a a a

SY Mild Steel

4

DNMG150404-SY 0.4 a a a C012

C013

150408-SY 0.8 a a a E013

ap (mm)

3

E036

2 150604-SY 0.4 a a a ─ 038

1 E041

0

150608-SY 0.8 a a a E042

0.1 0.3 0.5 H009

Light Cutting f (mm/rev) ─ 011

C Carbon Steel • Alloy Steel

4

DNMG150404-C 0.4 [[ C012

C013

150408-C 0.8 [[ E013

ap (mm)

3

E036

2 150604-C 0.4 [[ ─ 038

1 E041

0

150608-C 0.8 [[ E042

0.1 0.3 0.5 H009

Light Cutting f (mm/rev) ─ 011

MJ DNMG150404-MJ 0.4 a a a r a

C012

150408-MJ 0.8 a a a r a C013

Difficult-to-Cut Materials

4 150412-MJ 1.2 a a a E013

E036

ap (mm)

3

150416-MJ 1.6 a a a

2 ─ 038

1 150604-MJ 0.4 a a a

E041

0 0.1 0.3 0.5 150608-MJ 0.8 a a a E042

f (mm/rev)

150612-MJ 1.2 a a a H009

─ 011

Light Cutting 150616-MJ 1.6 a a a

* Please refer to A024 before using the SW breaker (wiper insert).

a : Inventory maintained in Japan. r : Non stock, produced to order only.

[ : Inventory maintained in Japan. To be replaced by new products.

A064 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-65-320.jpg)

![TURNING INSERTS [NEGATIVE]

55° DN TYPE INSERTS

WITH HOLE

DNMG 11 04 08- MS

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8 8

7 HZ 7 HX 7 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6 6

5 FY 5 FH 5 5 FH 5

GH Standard

4 4 SH 4 4 4

MH SW

3 3 3 3 3

SY GH

2 2 2 2 HZ 2

MW

NEG

MA

1 MS 1 MP 1 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

MS DNMG 110408-MS 0.8 a r a C012

Stainless Steel 150404-MS 0.4 a a a a a a a a a a a r a a C013

5 E013

4 150408-MS 0.8 a a a a a a a a a a a r a a

E036

ap (mm)

3

2 150412-MS 1.2 a r a a a a a a r a a ─ 038

1

150604-MS 0.4 a a a a a a a a r E041

0 0.1 0.3 0.5 E042

f (mm/rev) 150608-MS 0.8 a a a a a a a a r

H009

Medium Cutting 150612-MS 1.2 a a a a a ─ 011

R/L DNGG 150404R 0.4 a a[ a a

C012

150404L 0.4 a a[ a a C013

Carbon Steel • Alloy Steel

5 150408R 0.8 a a[ a a E013

4 E036

ap (mm)

3 150408L 0.8 a a[ a a

2 ─ 038

1 150604R 0.4 a a

E041

0 0.1 0.3 0.5 150604L 0.4 a E042

f (mm/rev)

150608R 0.8 a H009

─ 011

Medium Cutting 150608L 0.8 a

GH Carbon Steel • Alloy Steel

7

DNMG 150408-GH 0.8 a a a a a a a C012

C013

150412-GH 1.2 a a a a a a a E013

ap (mm)

5 E036

3 150608-GH 0.8 a a a a a a a ─ 038

E041

Semi-Heavy

1

0 0.1 0.3 0.5 0.7

150612-GH 1.2 a a a a a a a E042

H009

Cutting f (mm/rev) ─ 011

GJ DNMG 150408-GJ 0.8 a a a a a C012

Difficult-to-Cut Materials C013

7 150412-GJ 1.2 a a a a a

E013

E036

ap (mm)

5

150416-GJ 1.6 a a a a a

3 ─ 038

1

150608-GJ 0.8 a a E041

0 0.1 0.3 0.5 0.7

150612-GJ 1.2 a a E042

Semi-Heavy f (mm/rev) H009

Cutting 150616-GJ 1.6 a a ─ 011

HZ DNMM 150408-HZ 0.8 a a r r C012

Mild Steel C013

14 150412-HZ 1.2 a a r r

E013

E036

ap (mm)

10

150416-HZ 1.6 a a r r

6 ─ 038

2

150608-HZ 0.8 a a r r E041

0 0.2 0.6 1.0 1.4

150612-HZ 1.2 a a r r E042

f (mm/rev) H009

Heavy Cutting 150616-HZ 1.6 a a r r ─ 011

a : Inventory maintained in Japan. r : Non stock, produced to order only.

[ : Inventory maintained in Japan. To be replaced by new products.

A066 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-67-320.jpg)

![TURNING INSERTS [NEGATIVE]

RN TYPE INSERTS

WITH HOLE

RNMG 09 03 00

Size Thickness Corner Radius

TURNING INSERTS

* Please refer to page A002.

CHIP CONTROL RANGE FOR WORK MATERIALS Medium Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) M Stainless Steel ( < 200HB)

8 8 8

7 7 7

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6

5 5 5

4 Standard 4 Standard 4 Standard

3 3 3

2 2 2

NEG 1 1 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

Standard RNMG 090300 ─ a

Carbon Steel • Alloy Steel

5 120400 ─ a a r

4

ap (mm)

3 150600 ─ a

2 ─

1 190600 ─ a a a

0 0.1 0.3 0.5 250900 ─ a a

f (mm/rev)

Medium Cutting 310900 ─ a

M5 RNGJ190600-M5 ─ a a

C046

For Special Use

(For Rotary Tools)

a : Inventory maintained in Japan. r : Non stock, produced to order only.

[ : Inventory maintained in Japan. To be replaced by new products.

A068 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-69-320.jpg)

![TURNING INSERTS [NEGATIVE]

90° SN TYPE INSERTS

WITH HOLE

SNMG 09 03 04- C

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8

7 HZ 7 HX 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6

5 FY 5 FH 5 FH 5

GH Standard

4 4 SH 4 4

MH

3 3 3 3

SY GH

2 2 2 HZ 2

NEG

MA

1 MS 1 MP 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

C Carbon Steel • Alloy Steel

4

SNMG090304-C 0.4 [

090308-C 0.8 [ C014

ap (mm)

3

─ 018

2 120408-C 0.8 [[

1 E014

0

120416-C 1.6 [

E035

0.1 0.3 0.5

Light Cutting f (mm/rev)

R/L-1G Carbon Steel • Alloy Steel

4

SNMG120404R-1G 0.4 a

120404L-1G 0.4 a C014

ap (mm)

3

─ 018

2 120408R-1G 0.8 a

1 E014

0

120408L-1G 0.8 a E035

0.1 0.3 0.5

Light Cutting f (mm/rev)

MP Carbon Steel • Alloy Steel

5

SNMG120404-MP 0.4 a a a a

4 120408-MP 0.8 a a a a C014

ap (mm)

3 ─ 018

2 120412-MP 1.2 a a a a

1

E014

0 0.1 0.3 0.5 E035

Medium Cutting f (mm/rev)

MA SNMG120404-MA 0.4 a a a a r a a a

120408-MA 0.8 a a a a a a a a a a

Carbon Steel • Alloy Steel 120412-MA 1.2 a a a a a a a a a

5

4 120416-MA 1.6 a a C014

ap (mm)

3 ─ 018

2 150608-MA 0.8 a a a a r a

1

E014

0 0.1

150612-MA 1.2 a a a a r a r a E035

0.3 0.5

f (mm/rev) 150616-MA 1.6 a

190612-MA 1.2 a a a a a

Medium Cutting 190616-MA 1.6 a a a a r a a a

MH Carbon Steel • Alloy Steel

5

SNMG120404-MH 0.4 a a

4 120408-MH 0.8 a a a a a a C014

ap (mm)

3 ─ 018

2 120412-MH 1.2 a a a a a a

1

E014

0 0.1

190612-MH 1.2 a a a a E035

0.3 0.5

Medium Cutting f (mm/rev) 190616-MH 1.6 a a a a

a : Inventory maintained in Japan. r : Non stock, produced to order only.

[ : Inventory maintained in Japan. To be replaced by new products.

A070 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-71-320.jpg)

![TURNING INSERTS [NEGATIVE]

90° SN TYPE INSERTS

WITH HOLE

SNMM 15 06 12- HX

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8

7 HZ 7 HX 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6

5 FY 5 FH 5 FH 5

GH Standard

4 4 SH 4 4

MH

3 3 3 3

SY GH

2 2 2 HZ 2

NEG

MA

1 MS 1 MP 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

HX SNMM150612-HX 1.2 r r r r

150616-HX 1.6 r r r

Carbon Steel • Alloy Steel 190612-HX 1.2 a a r a

14

190616-HX 1.6 a a r a

ap (mm)

10

C014

6 190624-HX 2.4 a a r a

C016

2

0 0.2 0.6 1.0 1.4

250724-HX 2.4 a a r a

f (mm/rev) 250732-HX 3.2 r r a

250924-HX 2.4 a a r a

Heavy Cutting 250932-HX 3.2 r r a

HV Carbon Steel • Alloy Steel

14

SNMM190616-HV 1.6 a a r a

190624-HV 2.4 a a r a

ap (mm)

10

C014

6 250724-HV 2.4 a a r a

C016

2

0 0.2 0.6 1.0 1.4

250924-HV 2.4 a a r a

Heavy Cutting f (mm/rev)

HAS Carbon Steel • Alloy Steel

14

SNMG 250924-HAS 2.4 a a

ap (mm)

10

6 ─

2

0 0.2 0.6 1.0 1.4

Heavy Cutting f (mm/rev)

HXD Mild Steel

14

SNMM190612-HXD 1.2 a a

190616-HXD 1.6 a a

ap (mm)

10

C014

6 190624-HXD 2.4 a a

C016

2

0 0.2 0.6 1.0 1.4

250924-HXD 2.4 a a

Heavy Cutting f (mm/rev)

Flat Top SNMA 090304 0.4 a

090308 0.8 a a a a

Cast Iron 090312 1.2 r

7

120404 0.4 a C014

ap (mm)

5

─ 018

3 120408 0.8 a a a a a

E014

1

0 0.1 0.3 0.5 0.7

120412 1.2 a a a a a E035

f (mm/rev) 120416 1.6 a a a

190612 1.2 a a

190616 1.6 a a

a : Inventory maintained in Japan. r : Non stock, produced to order only.

A072 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-73-320.jpg)

![TURNING INSERTS [NEGATIVE]

60° TN TYPE INSERTS

WITH HOLE

TNMG 11 03 04- FH

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8 8

7 HZ 7 HX 7 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6 6

5 FY 5 FH 5 5 FH 5

GH Standard

4 4 SH 4 4 4

MH SW

3 3 3 3 3

SY GH

2 2 2 2 HZ 2

MW

NEG

MA

1 MS 1 MP 1 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

FH Carbon Steel • Alloy Steel TNMG110304-FH 0.4 a r

C020

3

160402-FH 0.2 a a a a a ─ 025

ap (mm)

2

160404-FH 0.4 a a a a a a E014

1

160408-FH 0.8 a a a a a a E035

0 0.1 0.2 0.3 0.4 E041

Finish Cutting f (mm/rev)

FS Mild Steel TNMG160404-FS 0.4 a a

C020

3

160408-FS 0.8 a a ─ 025

ap (mm)

2

E014

1

E035

0 0.1 0.2 0.3 0.4 E041

Finish Cutting f (mm/rev)

FY Mild Steel TNMG160404-FY 0.4 a a a

C020

3

160408-FY 0.8 a a a ─ 025

ap (mm)

2

E014

1

E035

0 0.1 0.2 0.3 0.4 E041

Finish Cutting f (mm/rev)

PK Carbon Steel • Alloy Steel TNGG 160404-PK 0.4 a [

C020

3

160408-PK 0.8 a [

─ 025

ap (mm)

2

E014

1

E035

0 0.1 0.2 0.3 0.4 E041

Finish Cutting f (mm/rev)

R/L-FS Carbon Steel • Alloy Steel

TNGG 160402R-FS 0.2 a

3 160402L-FS 0.2 a C020

─ 025

ap (mm)

2 160404R-FS 0.4 a

E014

1 160404L-FS 0.4 a

E035

0 0.1 0.2 0.3 0.4 160408R-FS 0.8 a E041

f (mm/rev)

Finish Cutting 160408L-FS 0.8 a

R/L-F Carbon Steel • Alloy Steel

TNGG 160402R-F 0.2 a a a

3 160402L-F 0.2 a a a C020

─ 025

ap (mm)

2 160404R-F 0.4 a a a

E014

1 160404L-F 0.4 a a a

E035

0 0.1 0.2 0.3 0.4 160408R-F 0.8 a a a E041

f (mm/rev)

Finish Cutting 160408L-F 0.8 a a a

a : Inventory maintained in Japan. r : Non stock, produced to order only.

[ : Inventory maintained in Japan. To be replaced by new products.

A074 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-75-320.jpg)

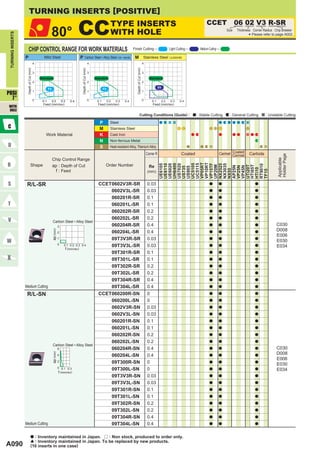

![TURNING INSERTS [NEGATIVE]

60° TN TYPE INSERTS

WITH HOLE

TNMG 16 04 04- MJ

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8 8

7 HZ 7 HX 7 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6 6

5 FY 5 FH 5 5 FH 5

GH Standard

4 4 SH 4 4 4

MH SW

3 3 3 3 3

SY GH

2 2 2 2 HZ 2

MW

NEG

MA

1 MS 1 MP 1 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

MJ Difficult-to-Cut Materials

4

TNMG160404-MJ 0.4 a a a r a

C020

160408-MJ 0.8 a a a r a ─ 025

ap (mm)

3

2 160412-MJ 1.2 a a a E014

1 E035

0 0.1 0.3 0.5 E041

Light Cutting f (mm/rev)

MP Carbon Steel • Alloy Steel

5

TNMG160404-MP 0.4 a a a a

C020

4 160408-MP 0.8 a a a a ─ 025

ap (mm)

3

2 160412-MP 1.2 a a a a E014

1

220408-MP 0.8 a a a a E035

0 0.1 0.3 0.5 E041

Medium Cutting f (mm/rev) 220412-MP 1.2 a a a a

MA TNMG160404-MA 0.4 a a a a a a a a a a

160408-MA 0.8 a a a a a a a a a a

Carbon Steel • Alloy Steel 160412-MA 1.2 a a a a a a a a a

5 C020

4 160416-MA 1.6 a a ─ 025

ap (mm)

3

2 220408-MA 0.8 a a a a a a a a E014

1

220412-MA 1.2 a a a a a a a a E035

0 0.1 0.3 0.5 E041

f (mm/rev) 220416-MA 1.6 a a

270608-MA 0.8 a a a a r

Medium Cutting 270612-MA 1.2 a a a a r a

MH Carbon Steel • Alloy Steel

5

TNMG160404-MH 0.4 a a a a a a

C020

4 160408-MH 0.8 a a a a a a ─ 025

ap (mm)

3

2 160412-MH 1.2 a a a a a a E014

1

220408-MH 0.8 a a a a a a E035

0 0.1 0.3 0.5 E041

Medium Cutting f (mm/rev) 220412-MH 1.2 a a a a a a

a : Inventory maintained in Japan. r : Non stock, produced to order only.

A076 (10 inserts in one case)](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-77-320.jpg)

![TURNING INSERTS [NEGATIVE]

60° TN TYPE INSERTS

WITH HOLE

TNGG 11 03 02 R

Size Thickness Corner Radius Chip Breaker

TURNING INSERTS

*

Please refer to page A002.

CHIP CONTROL RANGE FOR WORK MATERIALS Finish Cutting Light Cutting Medium Cutting Semi-Heavy Cutting Heavy Cutting

P Mild Steel P Carbon Steel • Alloy Steel (180─280HB) P Carbon Steel • Alloy Steel (Wiper) M Stainless Steel ( < 200HB) K Cast Iron ( < 350MPa)

8 8 8 8 8

7 HZ 7 HX 7 7 SH 7 Flat Top

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

Depth of Cut (mm)

6 6 6 6 6

5 FY 5 FH 5 5 FH 5

GH Standard

4 4 SH 4 4 4

MH SW

3 3 3 3 3

SY GH

2 2 2 2 HZ 2

MW

NEG

MA

1 MS 1 MP 1 1 MS 1

0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7 0 0.1 0.3 0.5 0.7

Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev) Feed (mm/rev)

WITH

HOLE

Cutting Conditions (Guide) : : Stable Cutting : General Cutting : Unstable Cutting

P Steel

M Stainless Steel

Work Material K Cast Iron

N Non-ferrous Metal

S Heat-resistant Alloy, Titanium Alloy

Coated

Corner R Coated Cermet Cermet Carbide

Holder Page

Chip Control Range

Applicable

VP05RT

VP10RT

Shape Order Number

UH6400

UC5105

UC5115

VP15TF

ap : Depth of Cut

UE6105

UE6110

UE6020

UE6035

US7020

NX2525

NX3035

RT9005

RT9010

Re

UP20M

HTi05T

UTi20T

AP25N

VP25N

US735

US905

HTi10

NX55

f : Feed

TF15

(mm)

R/L TNGG 110302R 0.2 a a a a

110302L 0.2 a a a

110304R 0.4 a a a a

110304L 0.4 a a a a

110308R 0.8 a a r

110308L 0.8 a a r a

160304R 0.4 a a a a

160304L 0.4 a a a a

160308R 0.8 a a a a

160308L 0.8 a a a

Carbon Steel • Alloy Steel

5 160402R 0.2 a a[ a a C020

4 ─ 025

ap (mm)

3 160402L 0.2 a a[ a a

2 E014

1 160404R 0.4 a a[ a a a

E035

0 0.1 0.3 0.5 160404L 0.4 a a[ a a a E041

f (mm/rev)

160408R 0.8 a a[ a a a

160408L 0.8 a a[ a a a

160412R 1.2 a a[ a r a

160412L 1.2 a a

220404R 0.4 a a[ a a

220404L 0.4 a a[ a a

220408R 0.8 a a[ a a a

220408L 0.8](https://image.slidesharecdn.com/turninginserts-130114002137-phpapp02/85/TURNING-INSERTS-79-320.jpg)