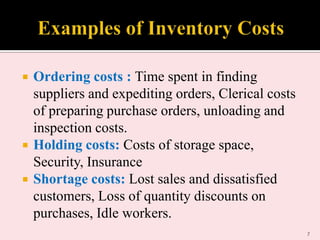

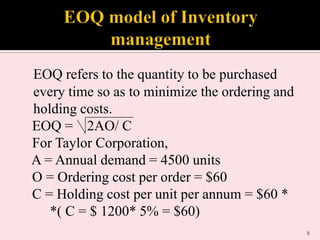

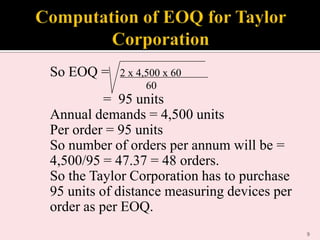

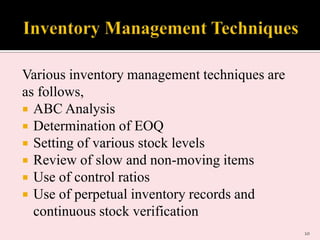

The document outlines the objectives and techniques of inventory management, emphasizing the importance of accurate forecasting and the balance between ordering, holding, and shortage costs. It details the economic order quantity (EOQ) model and its application for efficient inventory purchases. Various inventory management techniques, such as ABC analysis and perpetual inventory records, are also discussed.