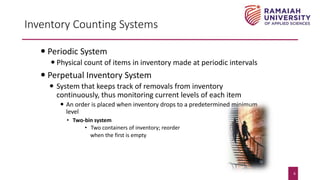

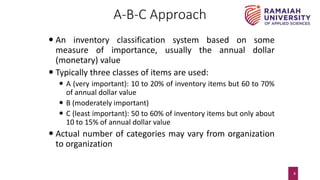

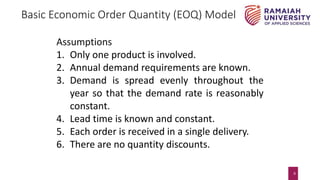

This document provides an overview of the Operations Management course taught by Dr. Chandra Sen Mazumdar. The course covers topics such as inventory management, the economic order quantity model, reorder points, safety stock, and technology in inventory management. It discusses inventory costs and classification systems. The document also summarizes key concepts and provides references for further reading.