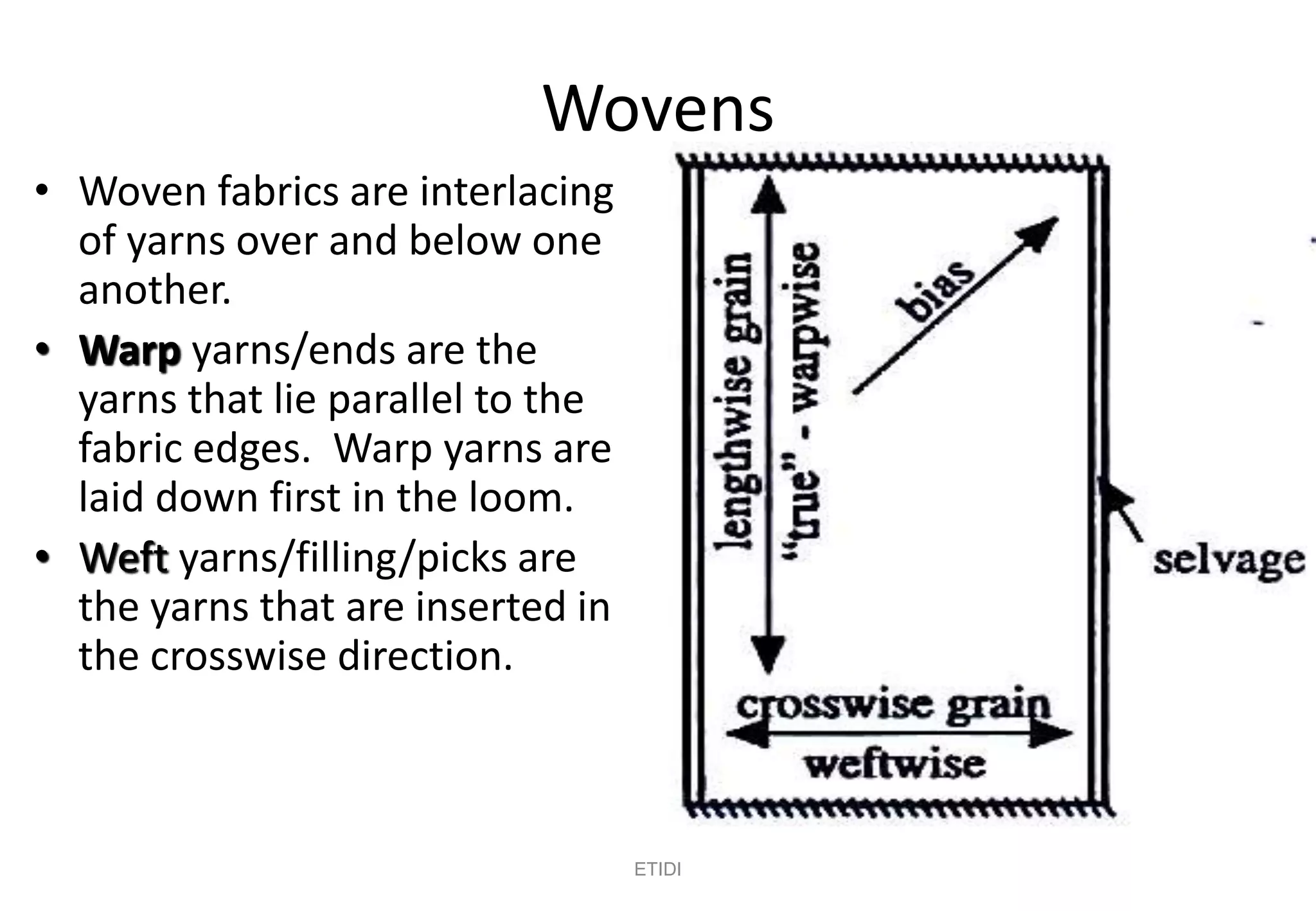

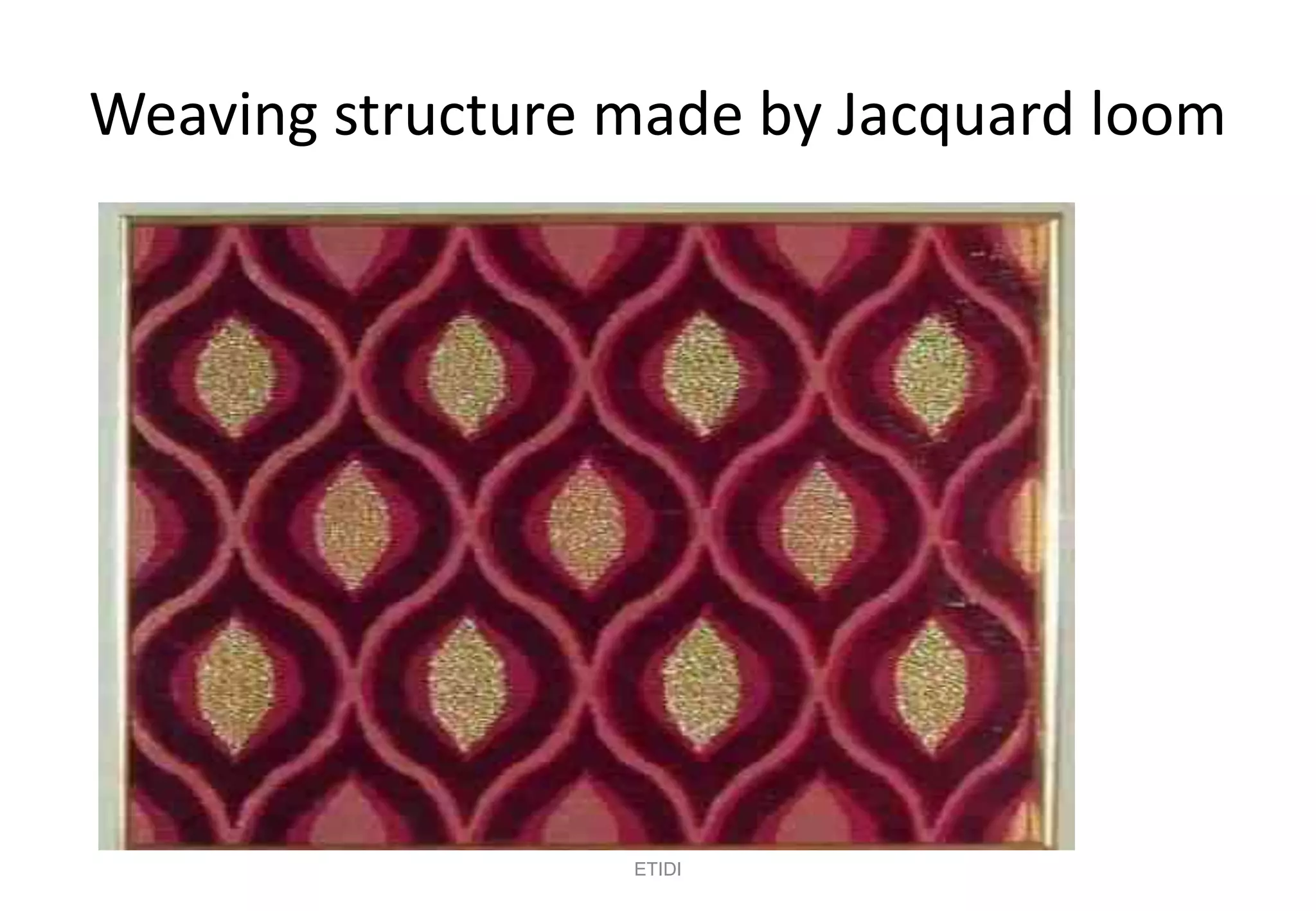

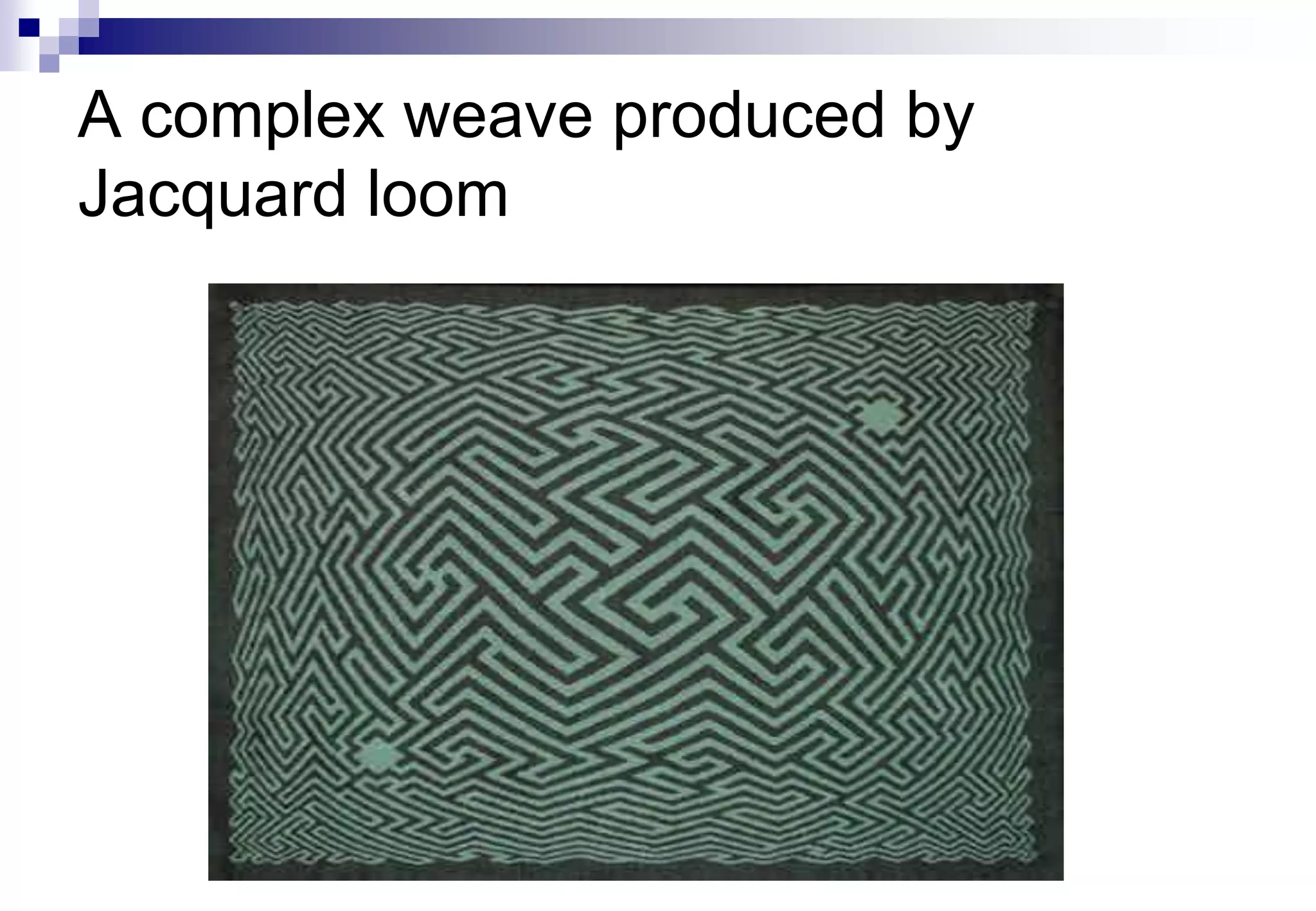

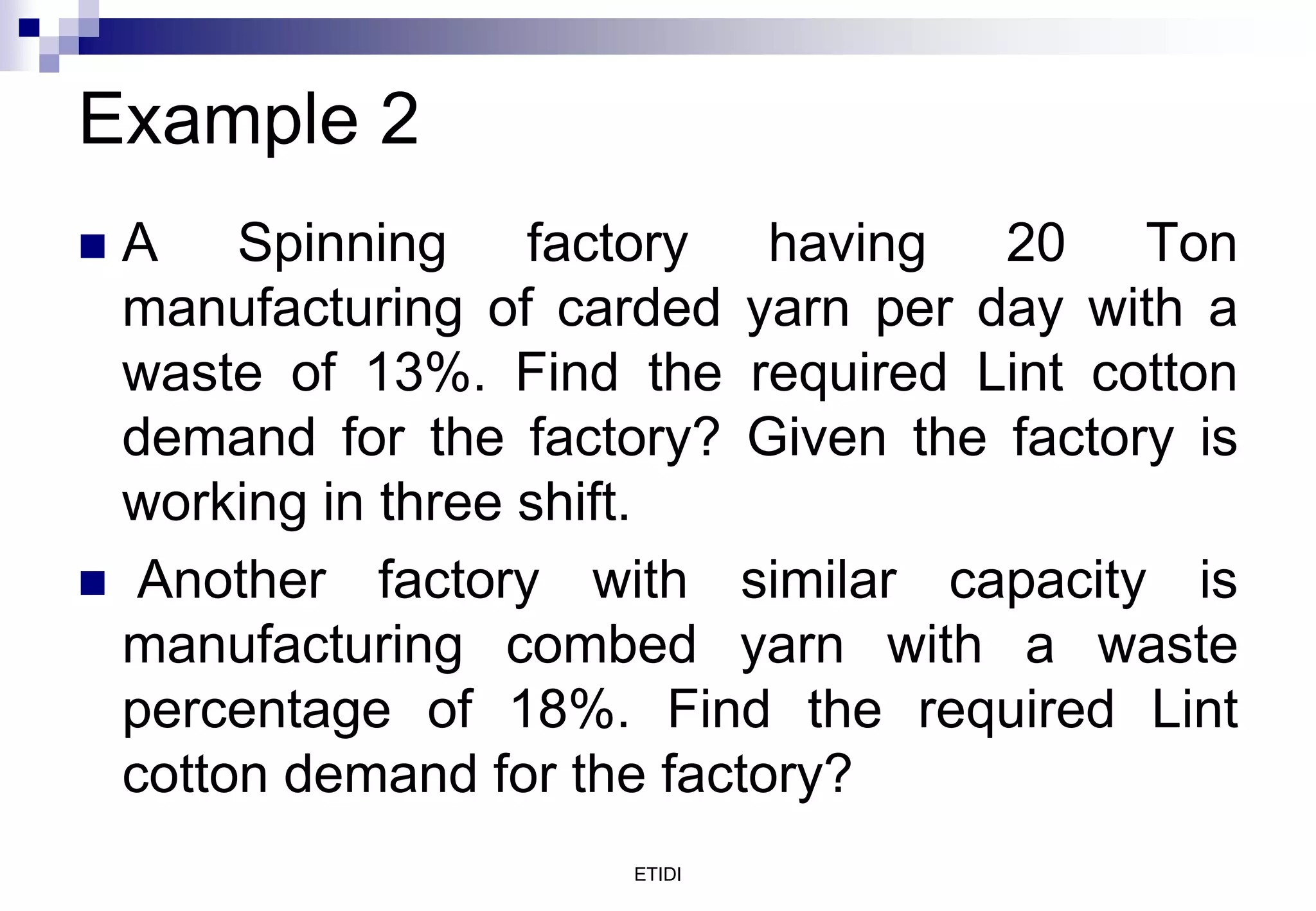

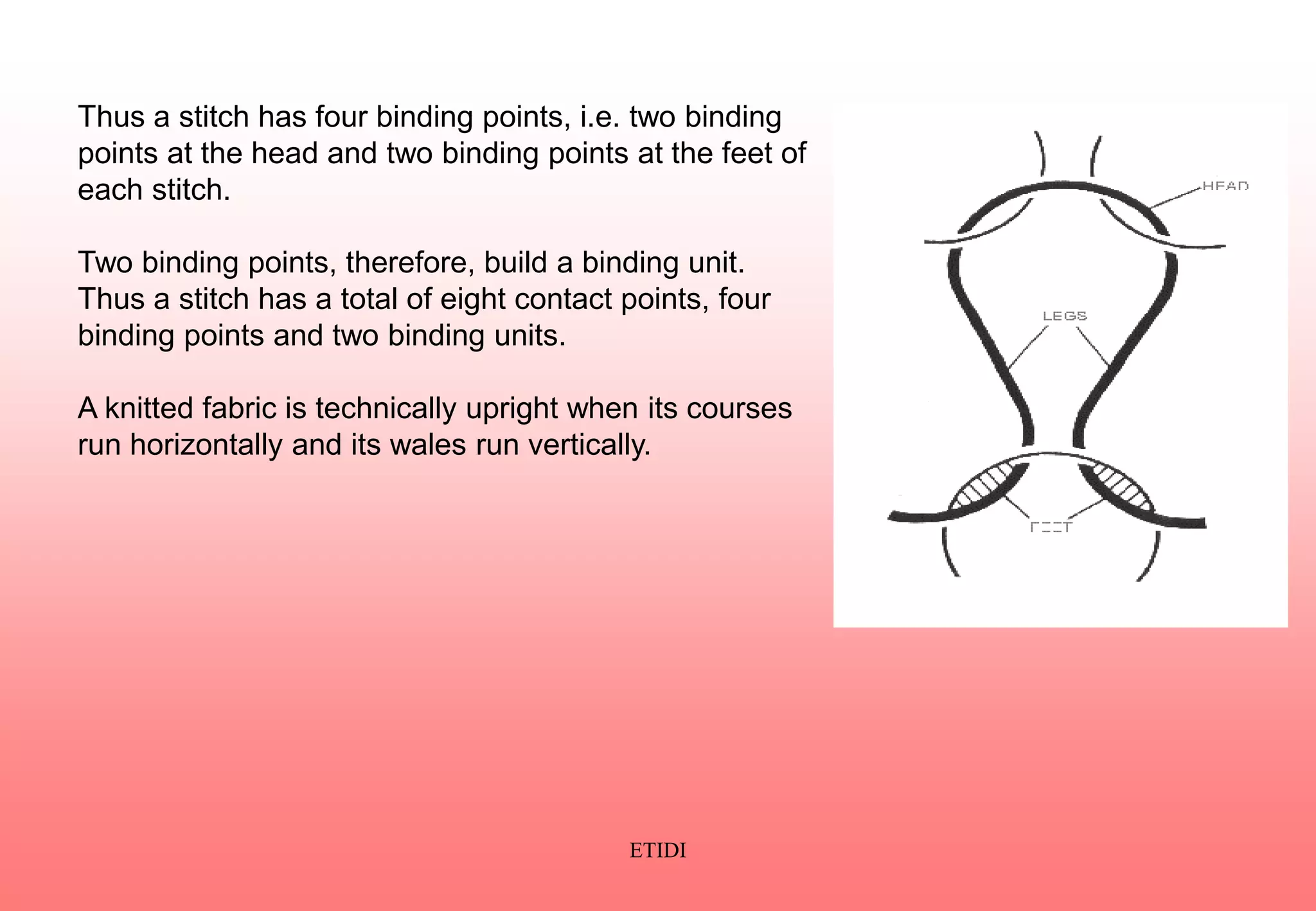

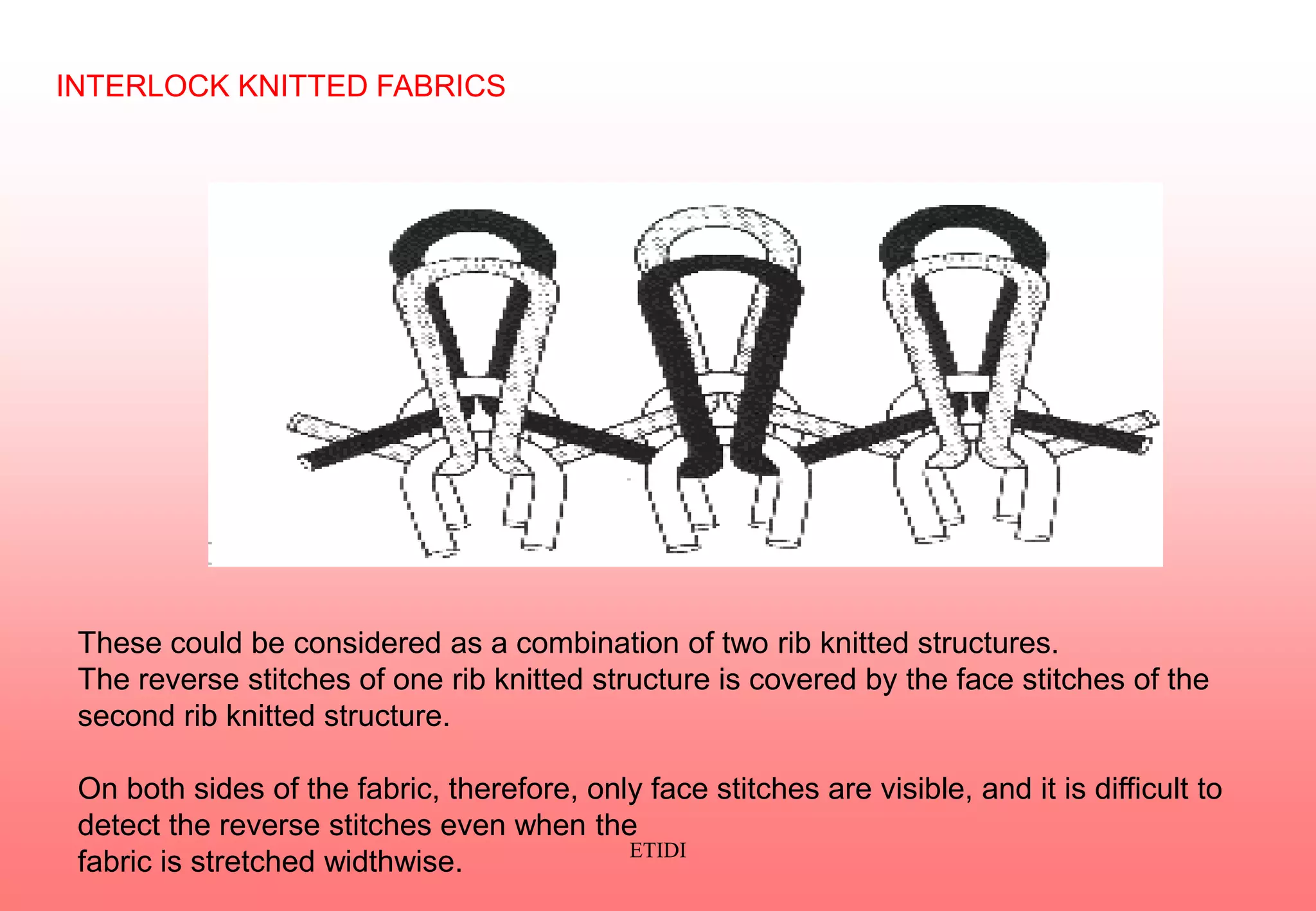

This document provides information on weaving machinery and processes. It discusses the objectives of training on weaving machines, which are to clarify machine types, evaluate project requirements, and increase awareness of the weaving process and technology. It describes the classification, types, and working principles of various weaving machines like shuttle looms, shuttleless looms (water jet, air jet, rapier, projectile), and their mechanisms. The document also covers preparatory processes like warping, sizing, and types of shedding motions like tappet, dobby, and jacquard that enable weaving different fabric structures.