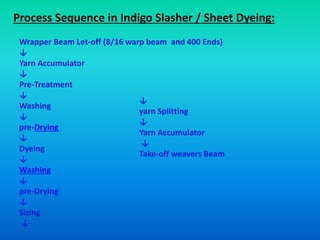

This document provides details about Abdullah Al Mahfuj's slasher dyeing machine presentation. It introduces slasher dyeing as a continuous process that dyes and sizes warp yarns in one operation by repeatedly passing the yarns through indigo dye baths before winding. It then outlines the key steps in slasher dyeing: warp beam let-off, yarn accumulation, pre-treatment, washing, pre-drying, dyeing, washing again, sizing, drying, and winding onto a take-up beam. Advantages are that slasher dyeing is less capital intensive, proven technology, lower production costs, shorter process time, and easy to operate machines.