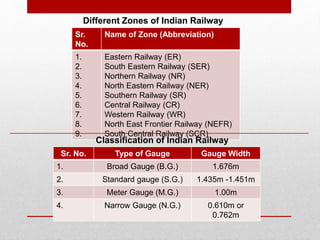

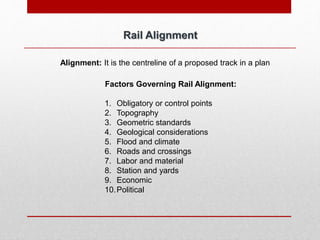

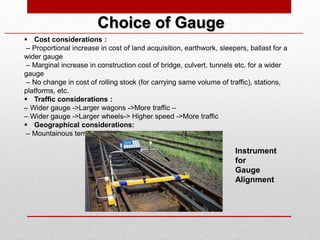

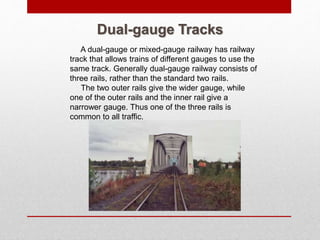

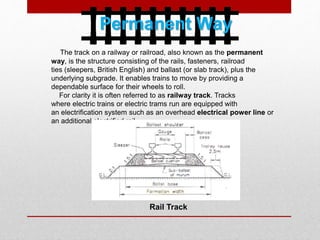

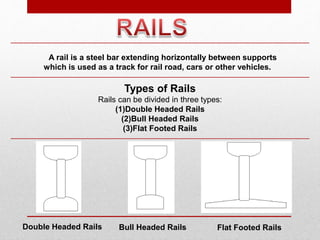

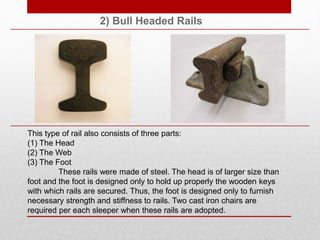

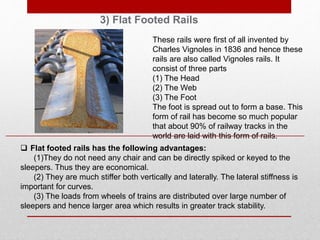

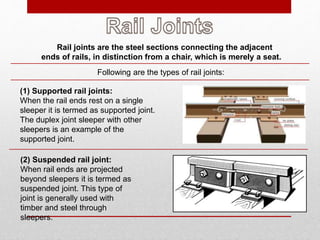

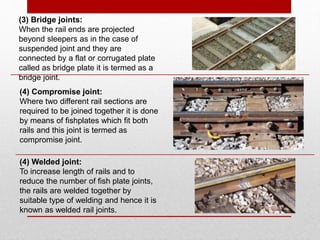

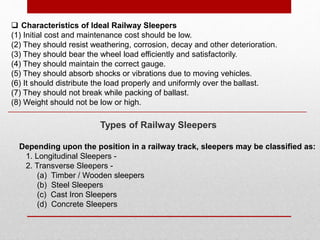

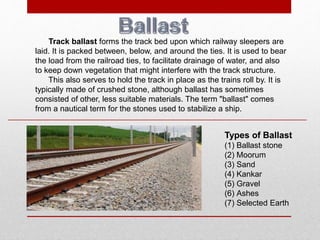

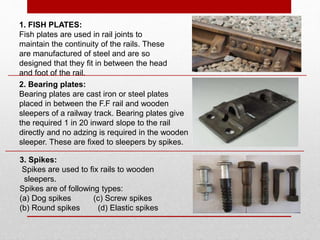

Rail transport involves trains running along parallel steel rails called a railway or railroad. The rails are placed on a foundation of concrete or other materials and are held in place by perpendicular sleepers made of timber, concrete, or steel. Indian railways began construction in the 1850s and now consists of multiple zones with different rail gauges. Rail alignment is influenced by terrain and other factors. Rails come in different types but flat footed rails are now most common. Rail joints connect adjacent rails while sleepers support the rails and distribute weight.