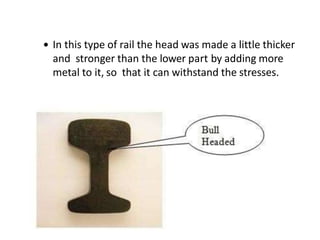

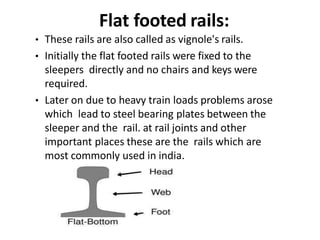

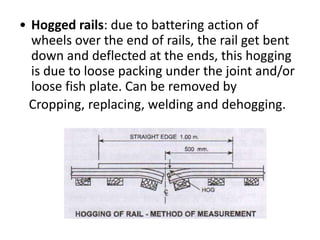

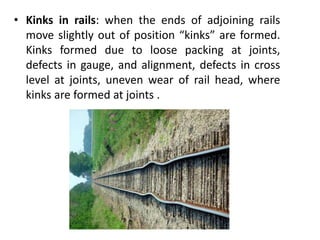

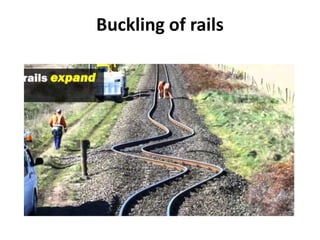

Rails provide a continuous and level surface for train movement, made from high-carbon steel to withstand various stresses. An ideal rail section must transfer loads efficiently while enduring lateral forces and wear, with specific requirements for jointing and stability. Various types of rails exist, including double-headed, bull-headed, and flat-footed rails, each with their own specifications and failure types such as hogging, kinks, and buckling.