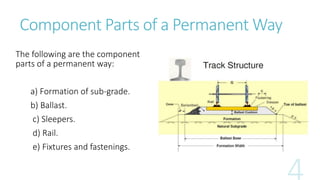

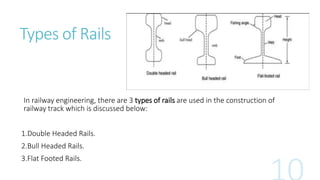

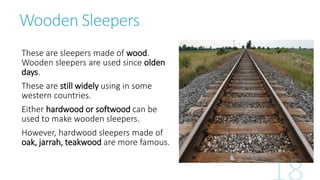

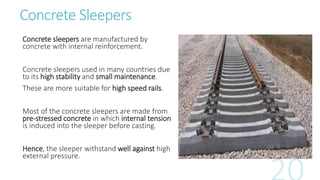

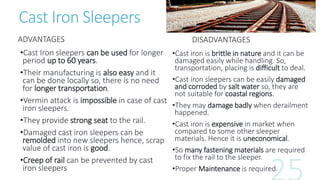

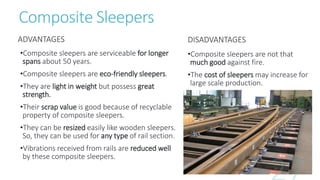

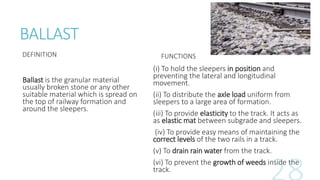

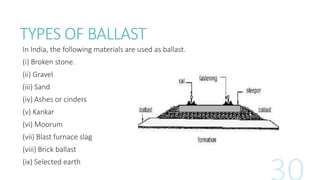

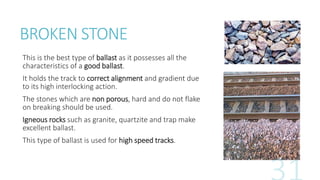

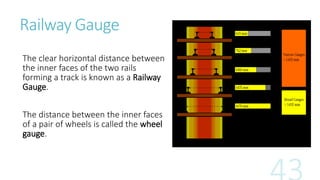

The document discusses the components and requirements of an ideal permanent way for railways. It describes that the permanent way consists of rails fitted on sleepers which rest on ballast and a subgrade. The key requirements for an ideal permanent way are proper gauge, alignment, gradient, drainage and minimal resistance. It also discusses different types of rails, sleepers and fastenings used in railway track construction.