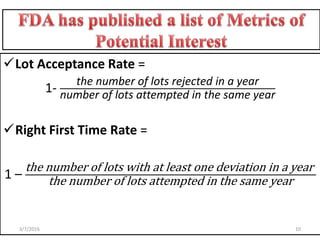

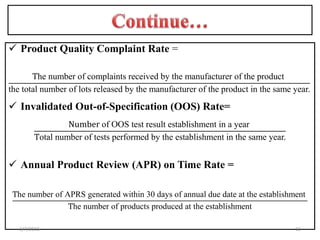

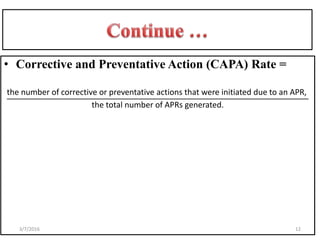

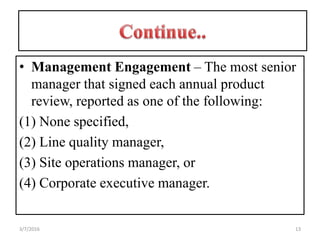

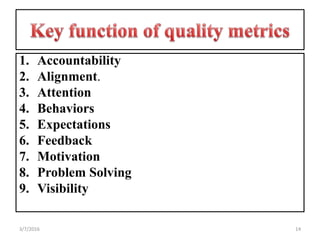

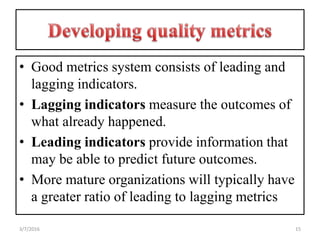

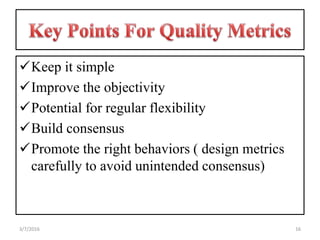

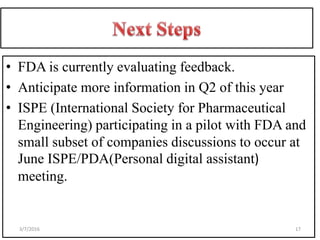

This presentation discusses quality metrics and how the pharmaceutical industry uses metrics. It defines quality metrics as elements that evaluate processes like customer satisfaction and defects. Metrics can help improve quality and productivity. The FDA requires metrics to evaluate manufacturing quality and reduce drug shortages. Guidelines like ICH Q8-Q11 provide a framework for using metrics flexibly to focus on quality. Leading and lagging metrics are discussed.

![Risk identification – systematic use of

information to identify potential sources of harm

(hazards) referring to the risk question or problem

description [ICH Q9 ]

Enables the detection of potential problems as

early as possible to plan corrective and preventive

actions

Important in achieving problem resolution and

problem prevention

93/7/2016](https://image.slidesharecdn.com/qualitymetrices-160307154257/85/Quality-metrices-9-320.jpg)