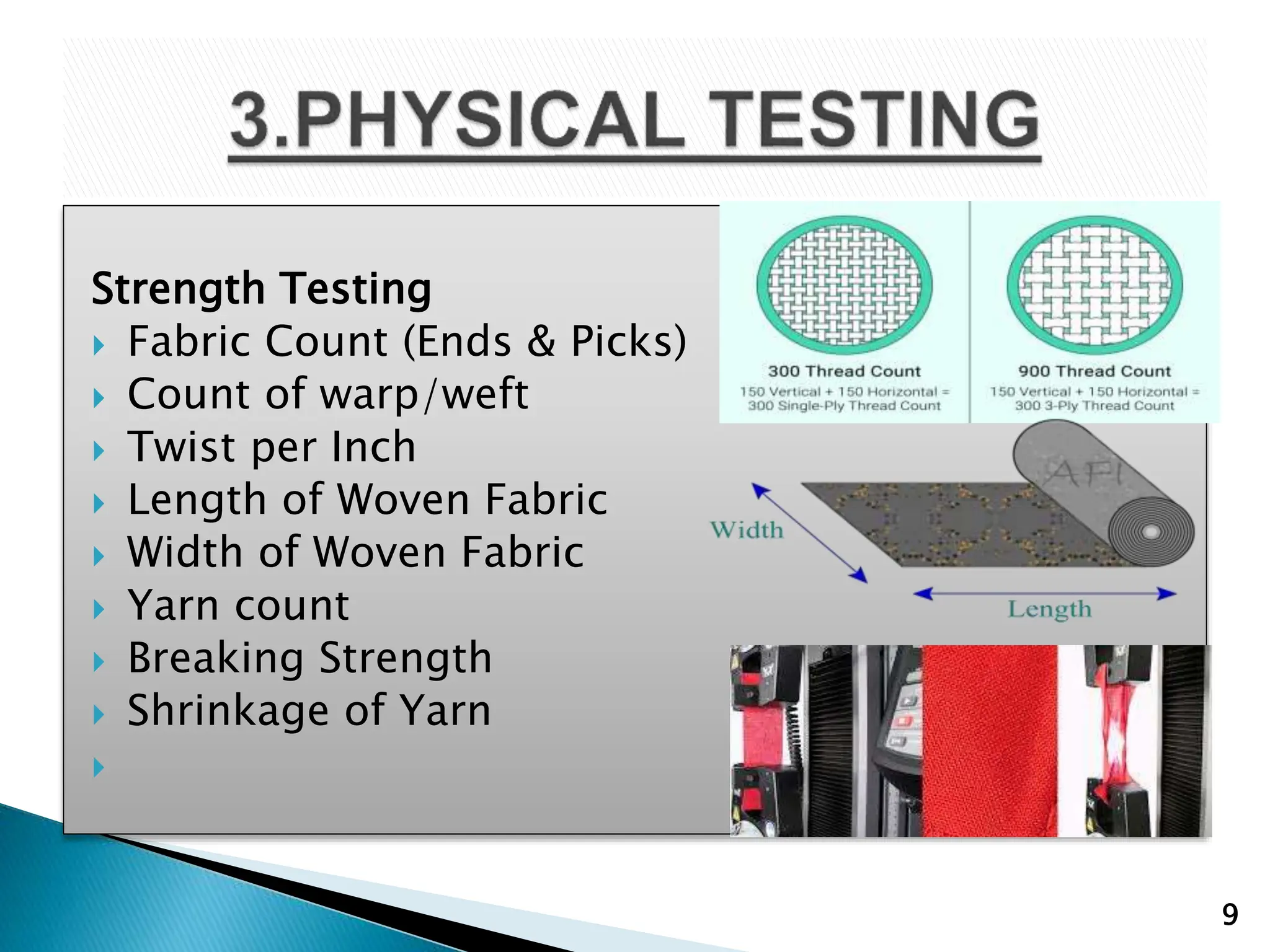

This document discusses textile testing, which is the process of determining a product's quality. Textile testing is important for certifying products and controlling different manufacturing processes. There are three main types of textile testing: chemical testing, fastness testing, and physical testing. Fastness testing evaluates how dyes withstand conditions like washing, crocking, perspiration, and exposure to light. Physical testing measures dimensional stability, strength, abrasion resistance, and other mechanical properties. Proper textile testing requires considering factors like the material, sample size, type of test, equipment, needed information, and accuracy.