This document discusses color fastness testing and quality control for textiles. It covers:

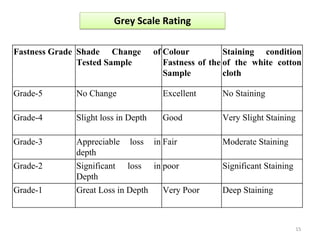

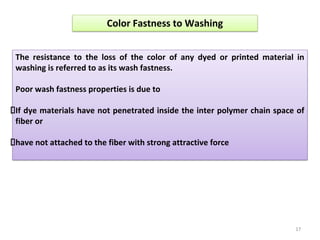

1. Color fastness is the resistance of a color to fading or bleeding from factors like washing, light, water, dry cleaning, and chemicals. It is assessed by changes in the sample color and staining of adjacent fabrics.

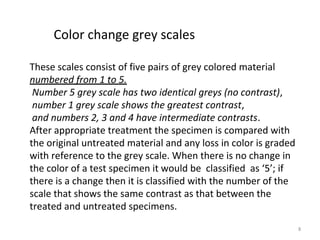

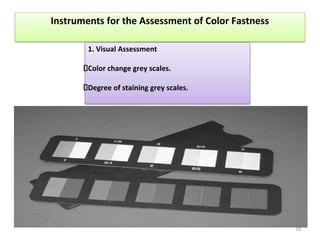

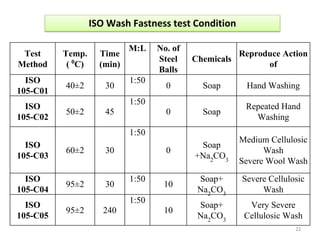

2. Various types of color fastness are described, including to washing, light, rubbing/crocking, perspiration, and more. Tests evaluate color change and staining on a scale of 1-5.

3. Factors like dye structure, bonding to fibers, shade depth, fiber chemistry, and test conditions impact color fastness properties. Standard tests and assessment methods following organizations