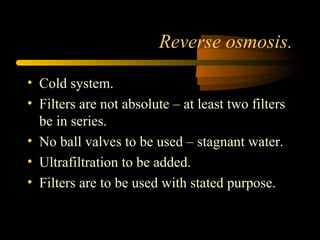

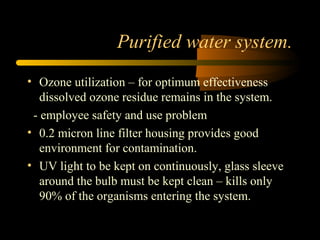

The document outlines the design, validation, and operational qualifications of water systems used in pharmaceuticals, emphasizing the importance of high-purity water for injection and purified water in manufacturing processes. It details the requirements for system design qualifications, installation procedures, performance testing, and microbial limits to ensure product quality and compliance with regulations. Key practices include periodic monitoring for contaminants, rigorous operational protocols, and documentation of any non-conformities.