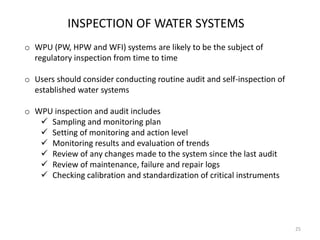

1) The document discusses validation of water systems for pharmaceutical use, including water quality specifications, purification methods, and commissioning, qualification, operation and maintenance of the systems.

2) It outlines various water grades including drinking water, purified water, highly purified water, and water for injections, and describes methods for producing each grade including distillation, ion exchange, ultrafiltration and reverse osmosis.

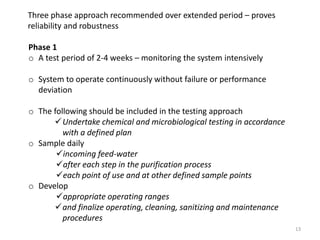

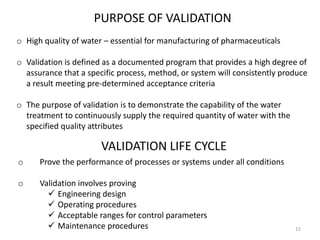

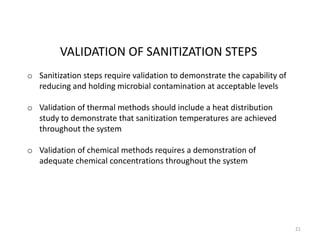

3) Validation of water systems aims to demonstrate the capability of the systems to consistently supply water meeting predetermined quality criteria through qualification testing over extended periods and under varying conditions.