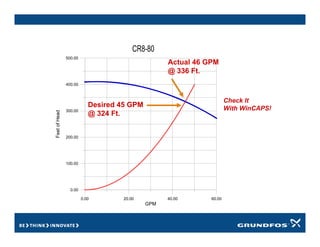

Cavitation occurs when the liquid vaporizes as it enters the impeller of a pump if the inlet pressure is too low. The vapor bubbles collapse under increased pressure as they exit the impeller, releasing energy that erodes the impeller and bearings. Cavitation can be avoided by ensuring the net positive suction head available (NPSHA) is greater than the net positive suction head required (NPSHR) for a given pump. NPSHA depends on factors like elevation, pressure, friction losses, and temperature. An example calculation demonstrates how to determine if NPSHA exceeds NPSHR to prevent cavitation for a specific pump application.