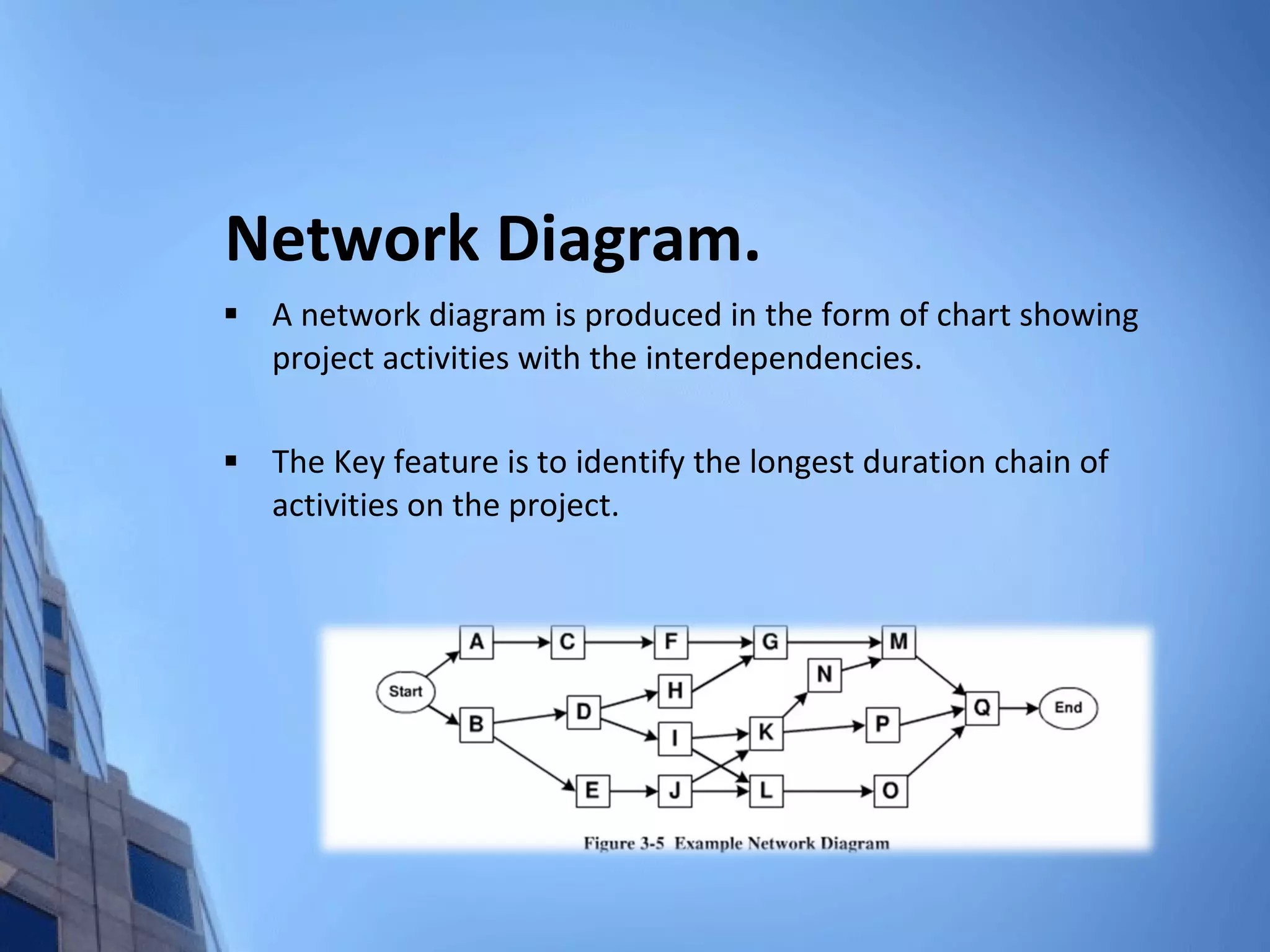

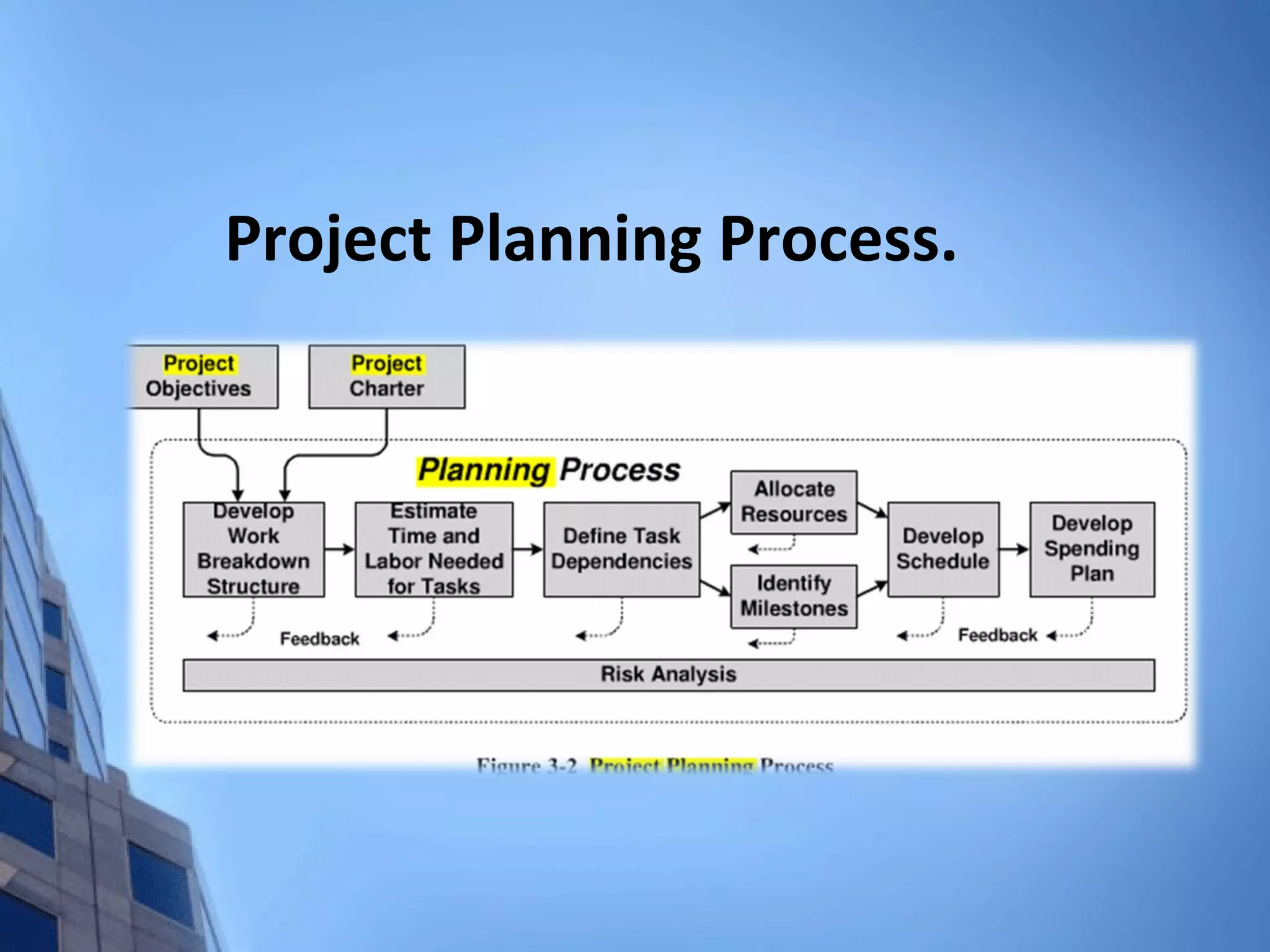

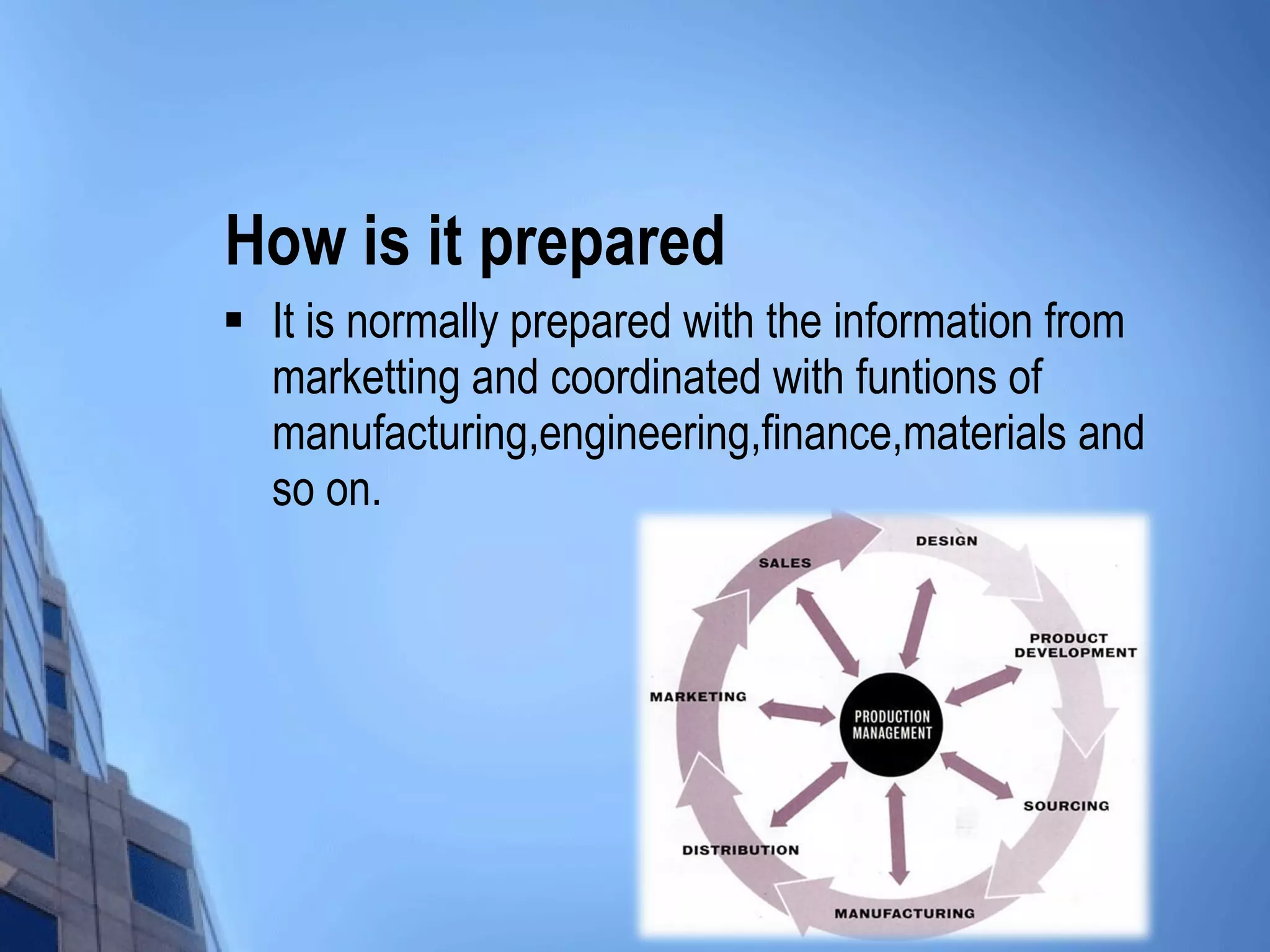

Project planning involves carefully breaking down a project into logical components using tools like the work breakdown structure and network diagrams to identify dependencies between tasks. This allows project teams to develop accurate schedules, usually in the form of Gantt charts, to coordinate resources and activities to achieve goals on time and on budget. Production planning establishes production rates and resource usage to satisfy customer demand as expressed in sales forecasts, while balancing inventory levels and maintaining a stable workforce over a 6-18 month horizon. The process begins with a sales forecast and may incorporate desired inventory changes to determine the production plan.