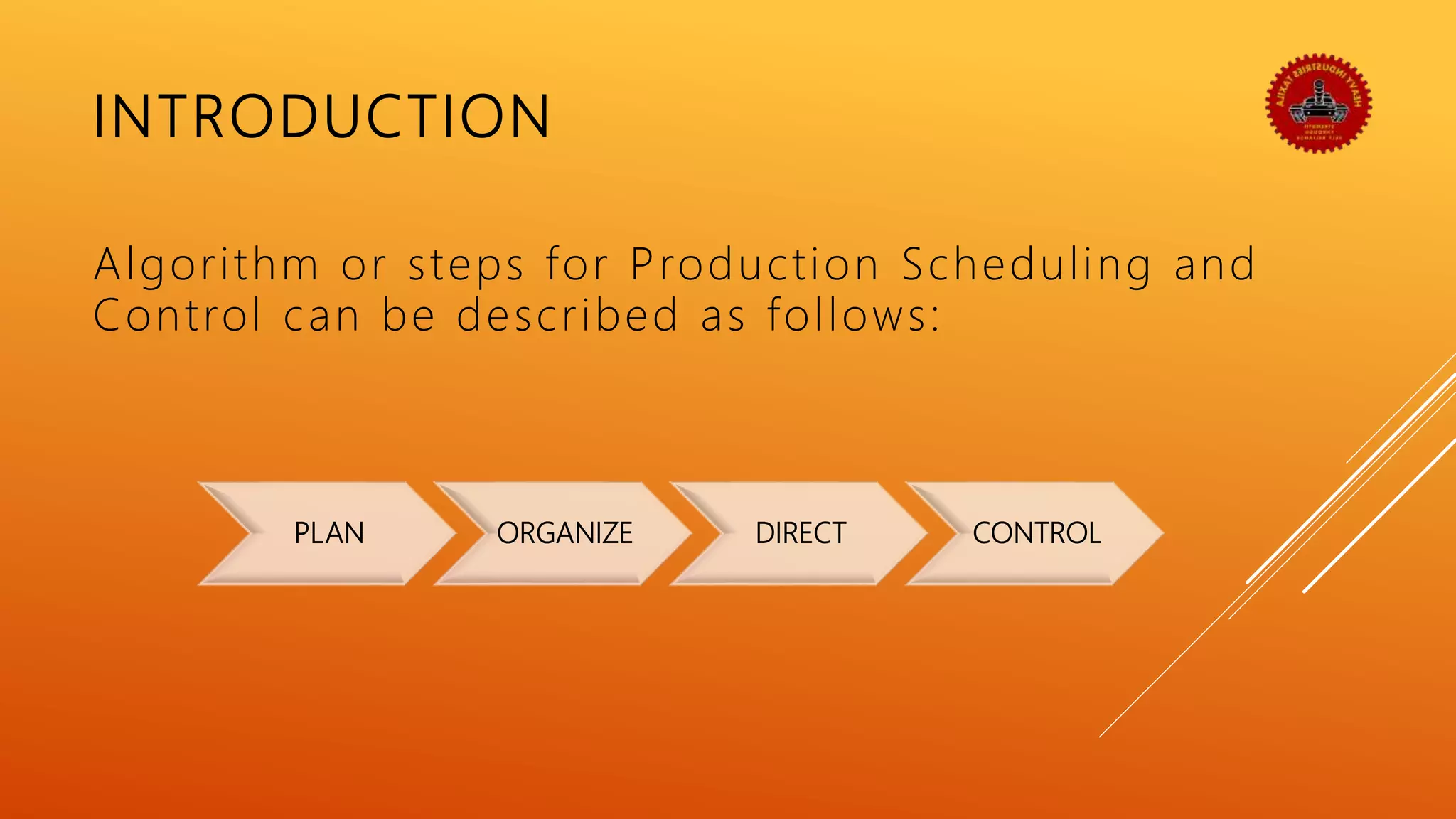

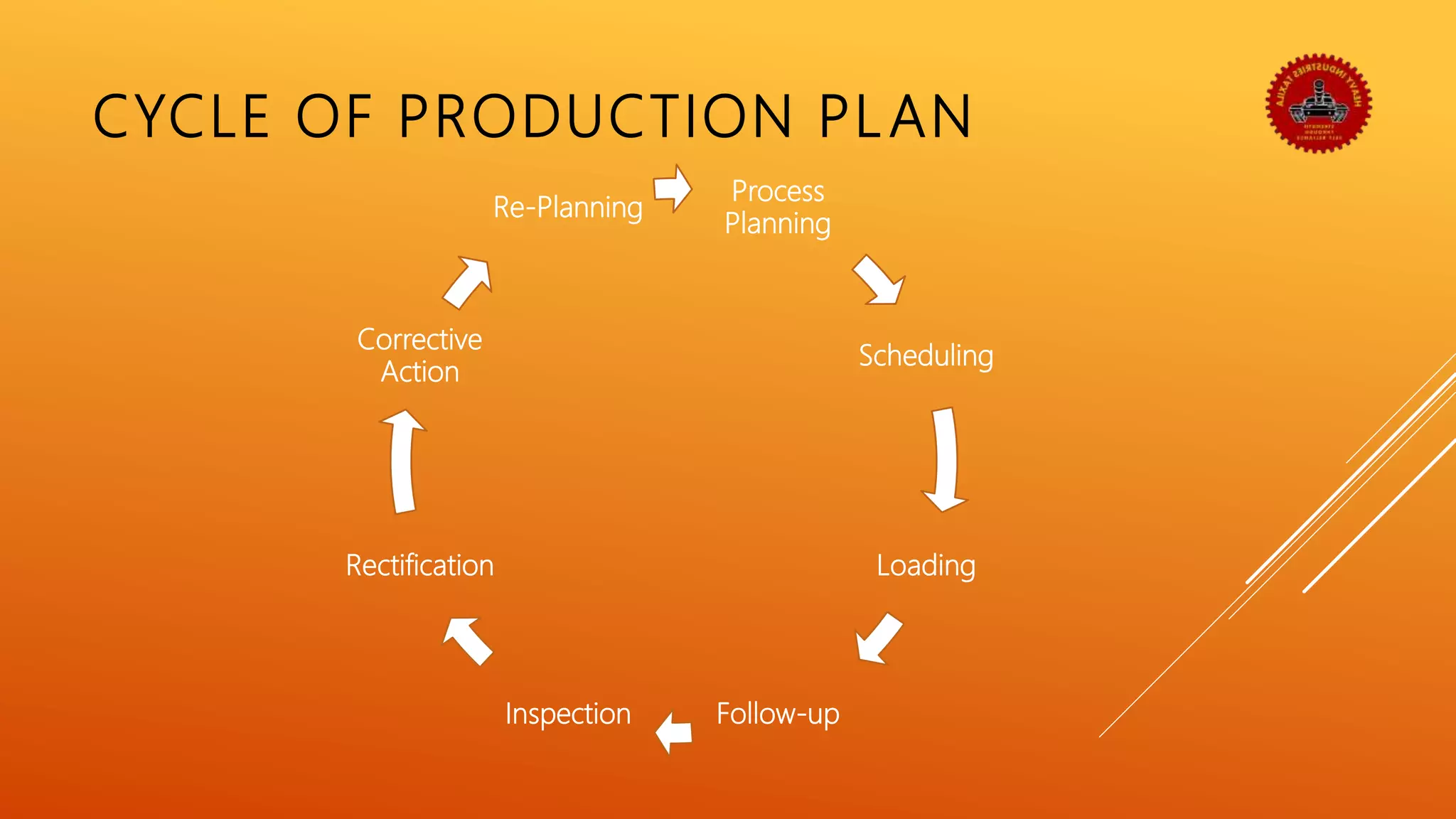

This document provides an overview of production scheduling and control. It discusses topics like introduction, aggregate production planning, demand forecasting, workforce planning, production routing, and production scheduling. The introduction defines production scheduling and control and its importance. Aggregate production planning involves medium-term planning to establish rough production levels. Demand forecasting predicts future requirements using qualitative, extrapolative, and causal methods. Workforce planning ensures the right workforce is available. Production routing determines the production path. Production scheduling sets timetables for manufacturing operations.