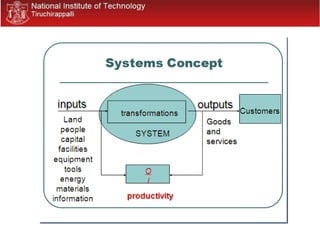

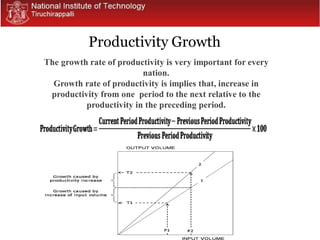

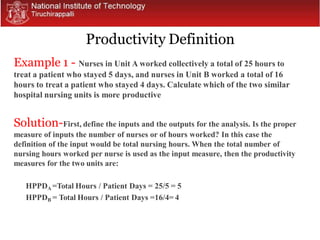

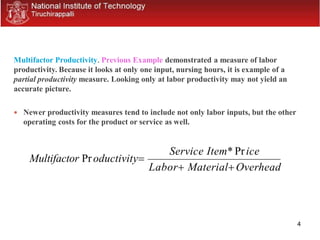

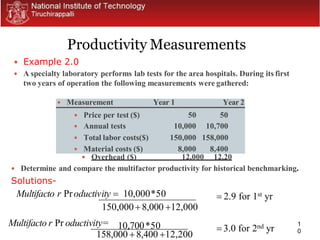

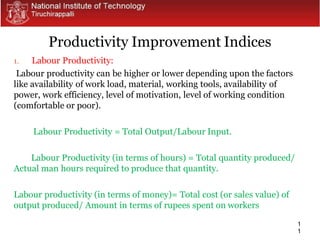

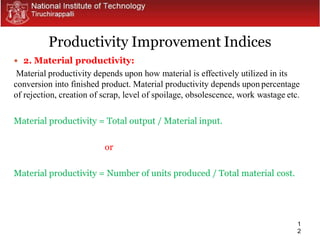

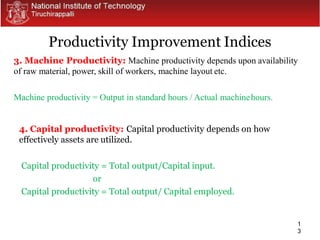

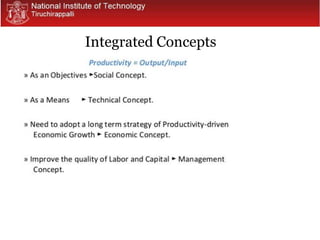

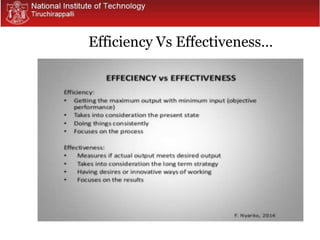

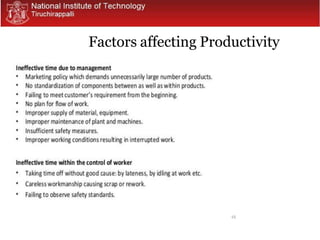

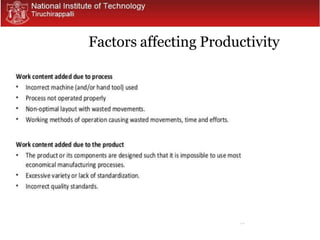

The document discusses definitions and concepts of productivity. It provides several definitions of productivity, including classical definitions that measure outputs relative to inputs needed. Productivity can be measured in various ways depending on the sector, such as hours to produce goods in a factory or revenue per employee in services. Higher productivity is important for economic growth and competitive advantage at the individual, organizational and national levels.

![25

B) HEIJUNKA: Heijunka focuses on achieving consistent levels of

production. It is defined as ‘distributing the production of different [bodytypes]

evenly over the course of a day’. It incorporates

1) The principles of line balancing by attempting to equate workloads

2) Leveling demand out by creating an inventory buffer and replenishing that

buffer.

It believes in providing even work load for all employees. Heijunka has the

capability of reducing lead times by minimizing time losses due to frequent

process changeovers.](https://image.slidesharecdn.com/productivitypresentation-mannukumar1-201217172211/85/Productivity-Personnel-Management-25-320.jpg)