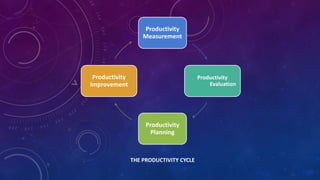

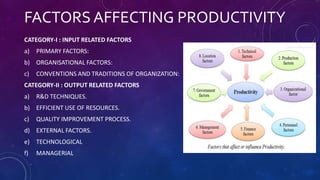

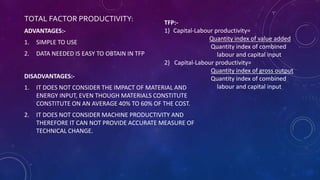

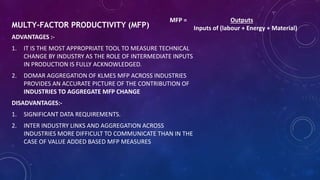

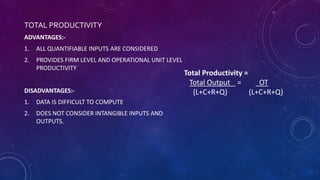

This document discusses productivity management. It defines productivity as the ratio of output to inputs. Productivity can be measured using trend, horizontal, vertical and budgetary analysis. Productivity involves measurement, evaluation, planning and improvement. Increased productivity benefits workers through higher pay and standards of living, and benefits organizations through higher production and profits. Factors affecting productivity include inputs, technology, management and external factors. Productivity can be improved through technology, employees, materials, processes and tasks. Common challenges in measuring productivity include measuring outputs and inputs accurately. Productivity models include partial, total factor, multi-factor and total productivity.