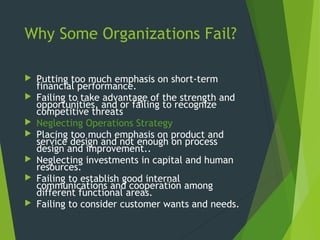

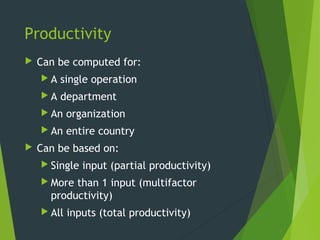

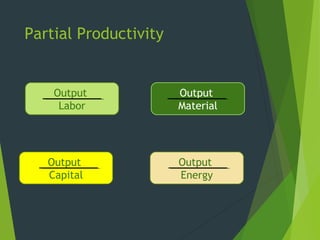

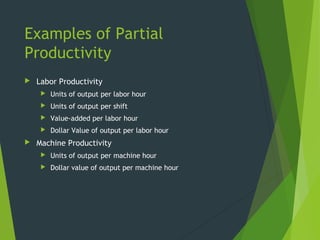

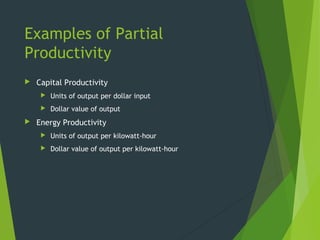

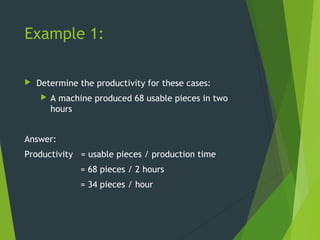

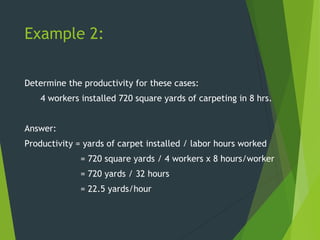

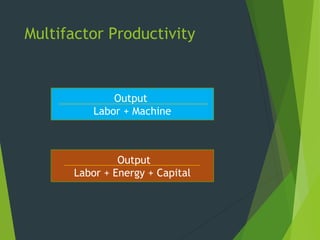

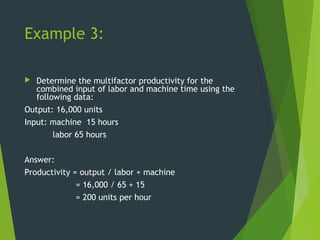

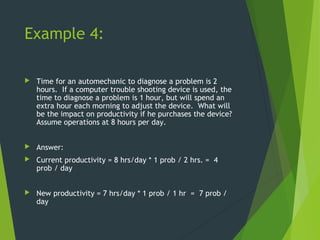

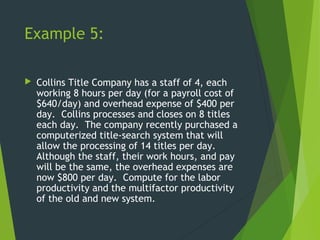

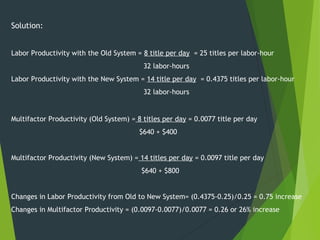

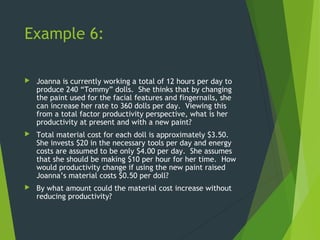

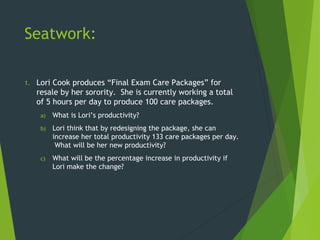

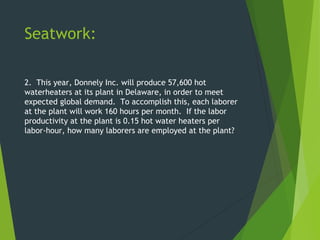

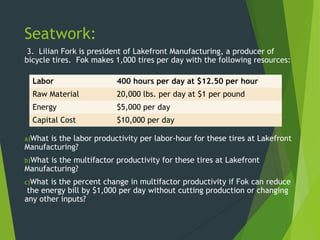

The document discusses competitiveness, strategy, productivity and operations management. It defines competitiveness and factors that influence it such as marketing, operations, and why some organizations fail. It also covers productivity measurement, factors that affect productivity, and examples for calculating different types of productivity.