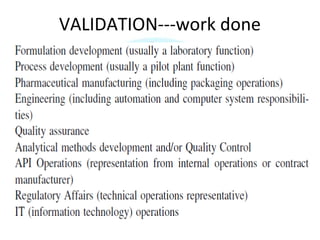

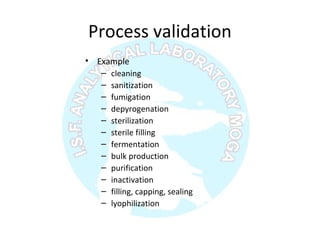

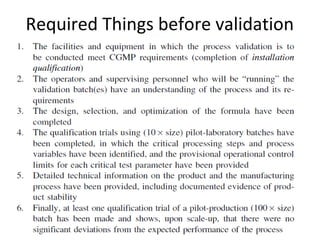

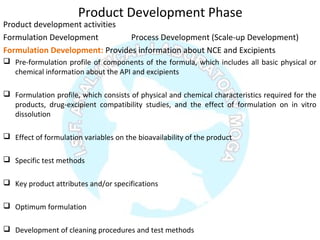

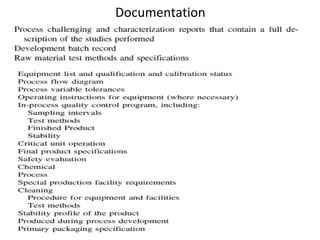

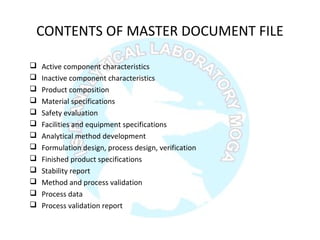

The presentation by Dr. Arti R. Thakkar discusses the essentials of process validation in pharmaceutical production, defining it as the documented evidence ensuring that processes consistently produce products meeting predetermined specifications. It covers the types of validation—prospective, concurrent, retrospective, and revalidation—along with the need for thorough documentation and control measures to minimize variability and ensure product quality. Key aspects include the roles of various stakeholders in validation, the critical importance of Good Manufacturing Practices (GMP), and the implementation of change control procedures to maintain quality throughout the manufacturing process.