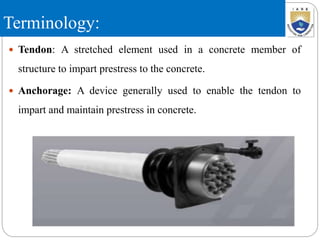

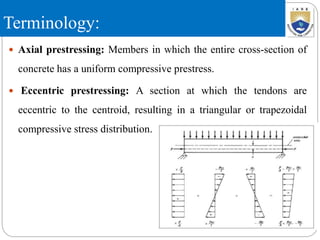

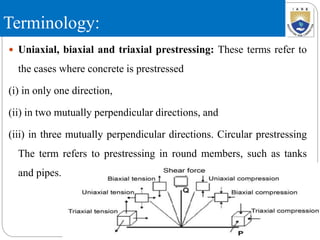

The document discusses prestressed concrete structures, including the basic concepts and various terminology related to prestressing techniques such as pretensioning and post-tensioning. It highlights the necessity for high-grade concrete and steel to enhance bond strength and minimize losses, emphasizing the importance of different grades for different prestressing methods. Furthermore, it outlines the stages of loading in prestressed concrete analysis, covering initial, intermediate, and final loading stages.