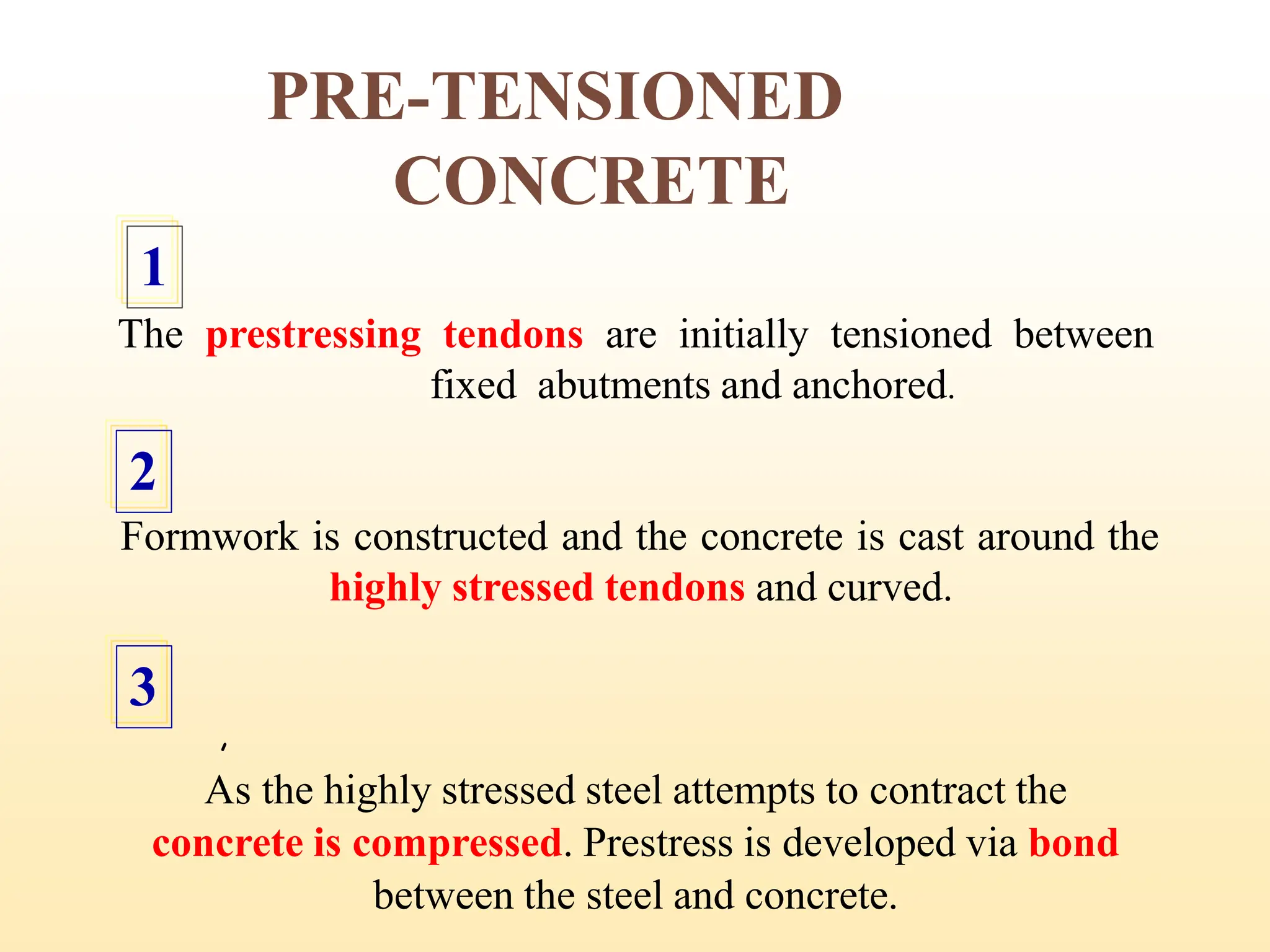

This document provides an outline for lectures on prestressed concrete, including basic concepts, materials, flexural analysis, design considerations, shear/torsion, loss of prestress over time, composite beams, and deflections. Key points covered include how prestressing controls cracking by applying compressive stresses to concrete before service loads; common prestressing methods of pre-tensioning and post-tensioning; estimating stresses in uncracked concrete beams using elastic theory; and accounting for various load stages in analysis and design.

![1. Basic Concepts [Introduction, Stress Control by

Prestressing, Partial Prestressing, Prestressing Methods,

Changes in Prestress Force]

2. Materials [Introduction to High Strength Steel, Types of

Prestressing Steel, Stress-Strain Properties of Steel, Steel

Relaxation, Types of Concrete, Concrete in Uniaxial

Compression and Tension, Time dependent Deformation

of Concrete]

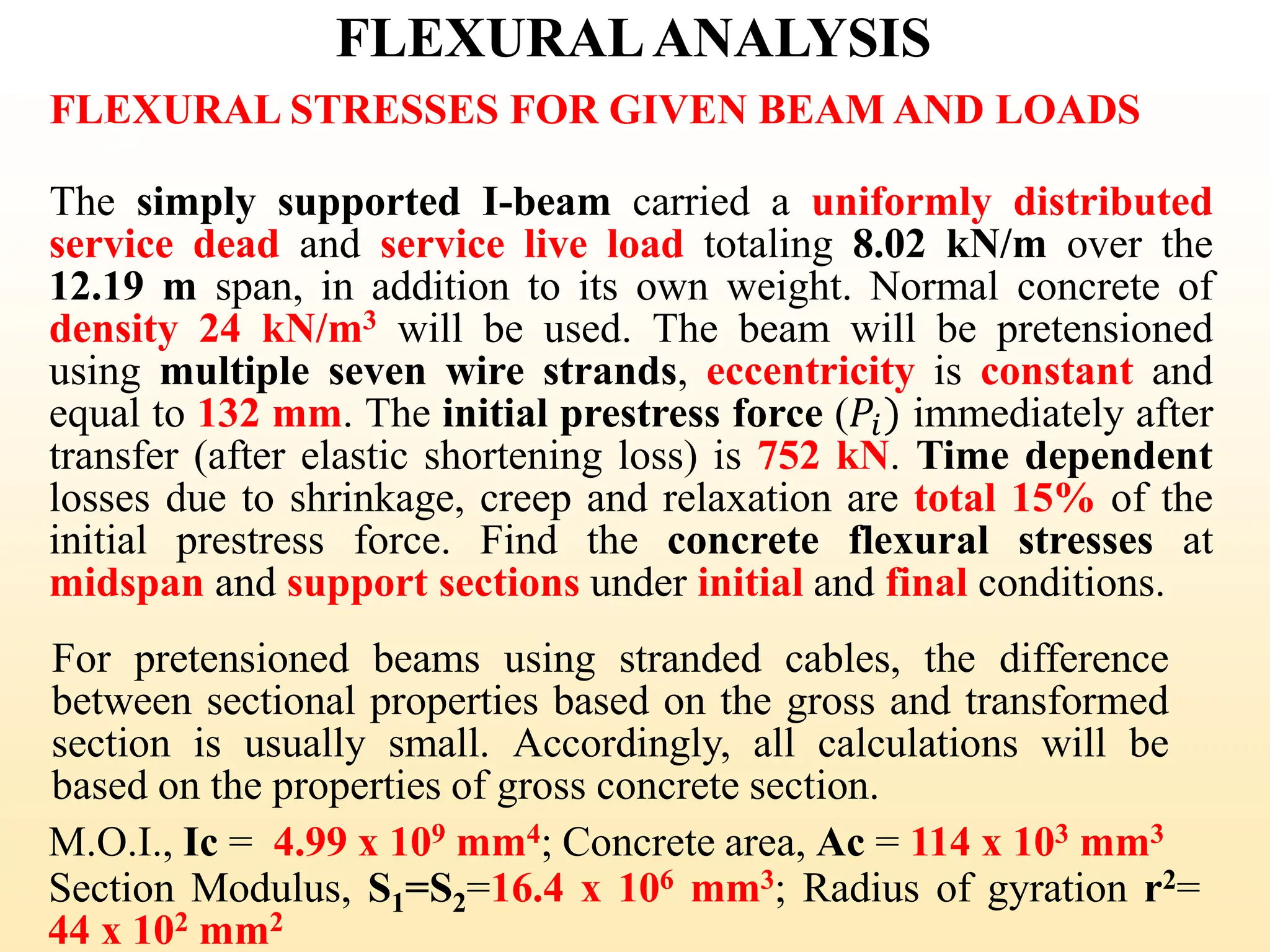

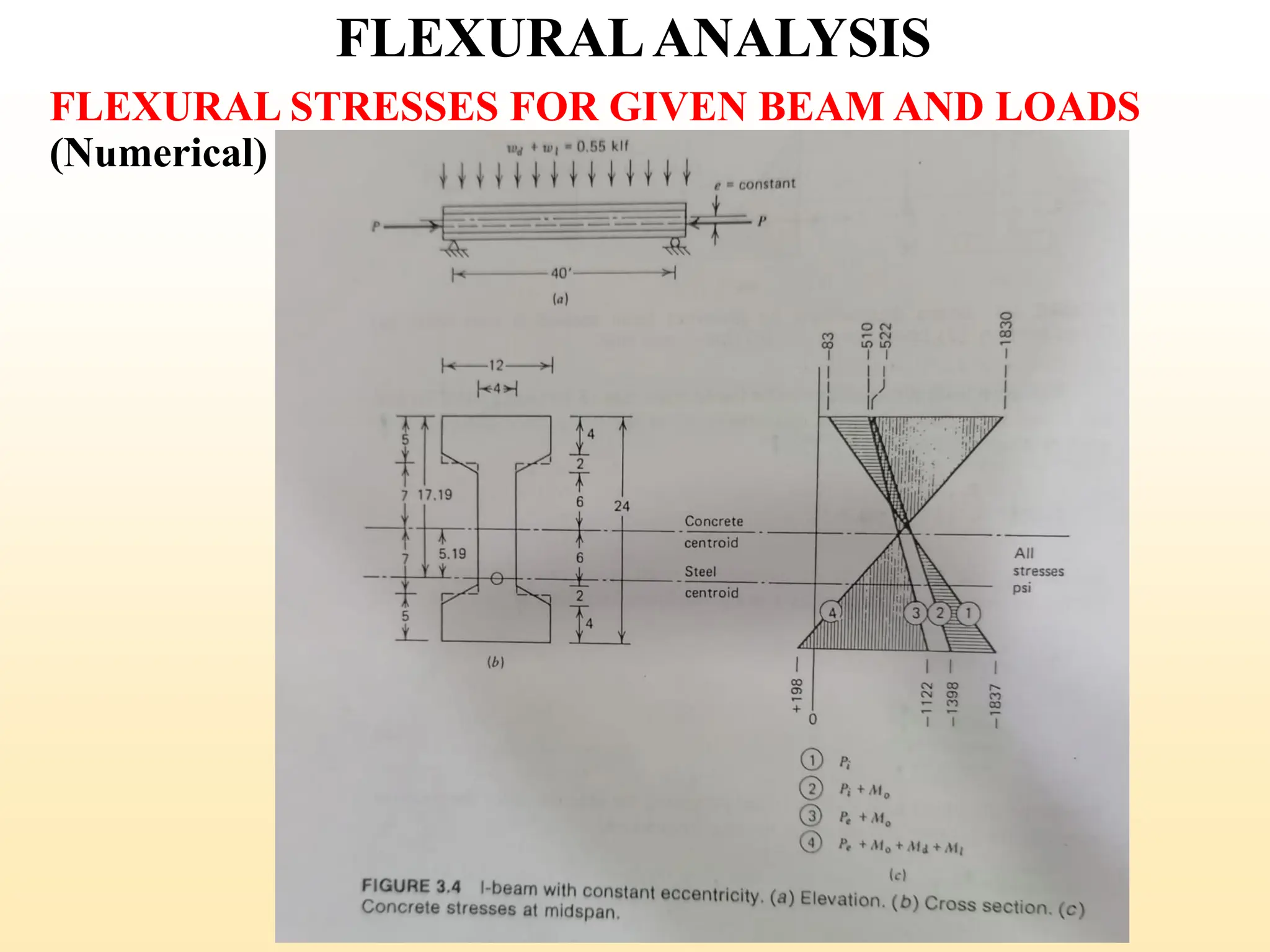

3. Flexural Analysis [Partial loss of Prestress Force, Elastic

Flexural Stresses in Uncracked Beams, Allowable

Flexural Stresses, Cracking Load, Flexural Strength

Analysis and ACI Design Equations, Partial Prestressing,

Elastic Flexural Stress after Cracking and Strength of

Partially Prestressed Beams]

LECTURE OUTLINE

2](https://image.slidesharecdn.com/1-basicsofprestressedconcrete-240315182453-f12c6d06/75/1-Basics-of-Prestressed-Concrete-pdforgs-2-2048.jpg)

![4. Flexural Design [Basis of Design, Flexural Design based on

Allowable Stresses, Shape Selection and Flexural Efficiency,

Load Balancing, Flexural design Based on Partial

Prestressing , Flexural Crack Control]

5. Shear and Torsion [Shear and Diagonal Tension in

Uncracked Beams, Diagonal Cracking Shear, Web

Reinforcement for Shear, Shear Design Criteria based on

ACI Criteria, Torsion in Concrete Structures, Torsion Design

of Prestressed Concrete]

6. Partial Loss of Prestress Force [Detailed Estimation of

Losses, Losses due to Friction, Anchorage Slip, Elastic

Shortening of Concrete, Creep and Shrinkage in Concrete,

Relaxation of Steel]

LECTURE OUTLINE

3](https://image.slidesharecdn.com/1-basicsofprestressedconcrete-240315182453-f12c6d06/75/1-Basics-of-Prestressed-Concrete-pdforgs-3-2048.jpg)

![7. Composite Beams [Types of Composite Construction, Load

Stages, Section Properties, Elastic Flexural Stresses, Flexural

Strength, Horizontal Shear Transfer, Shear and Diagonal

Tension]

8. Deflections [Basis for Calculations, Approximate Method

for Deflection Calculation, Deflection of Partially Prestressed

Beams, Allowable Deflections]

LECTURE OUTLINE

4](https://image.slidesharecdn.com/1-basicsofprestressedconcrete-240315182453-f12c6d06/75/1-Basics-of-Prestressed-Concrete-pdforgs-4-2048.jpg)