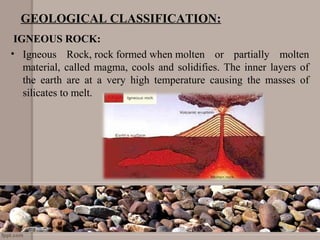

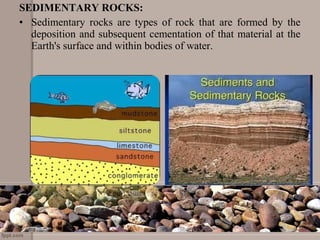

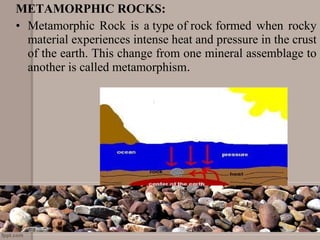

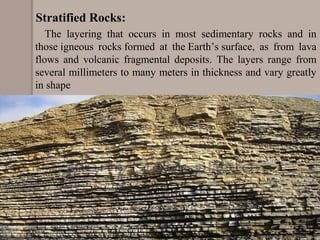

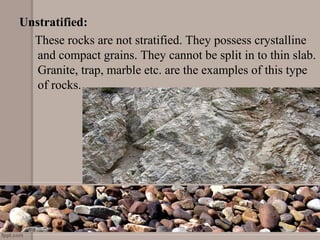

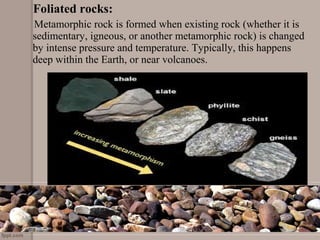

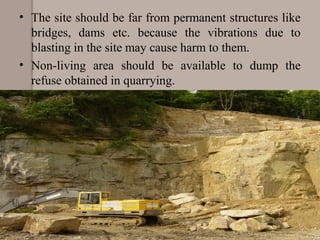

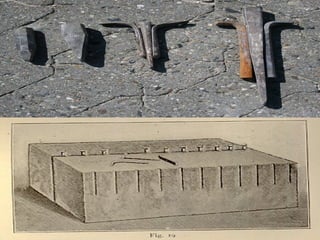

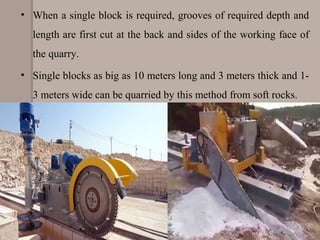

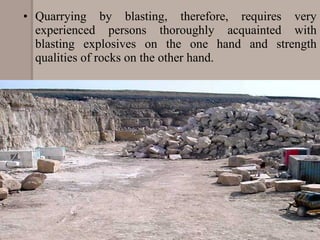

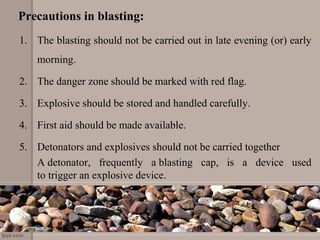

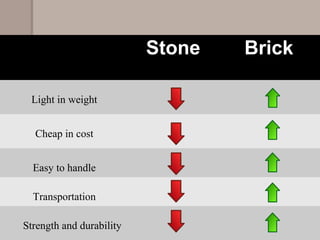

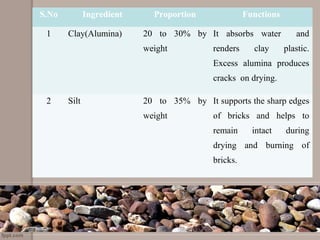

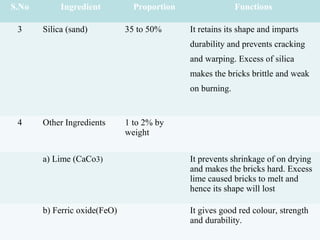

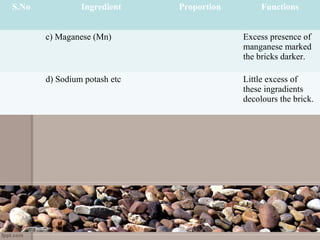

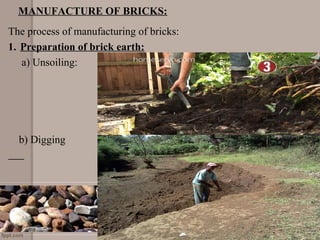

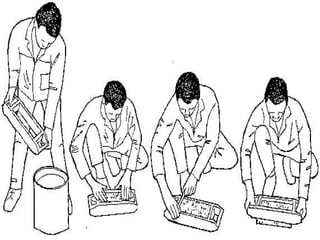

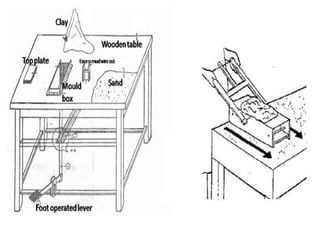

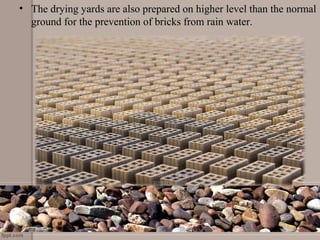

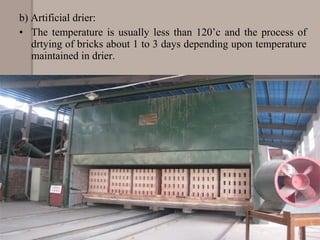

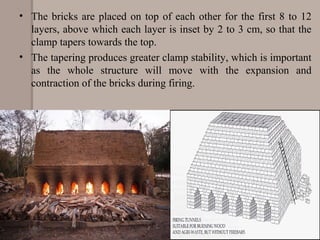

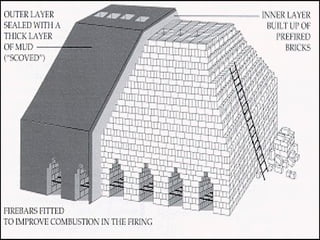

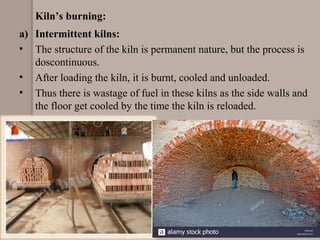

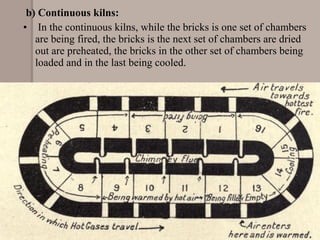

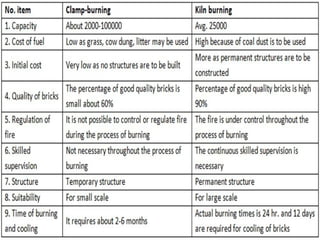

The document details construction planning and the classification of stones, discussing geological, physical, and chemical classifications of rocks. It also covers the processes of stone quarrying, methods of extracting stones, and the dressing of stones to achieve desirable shapes and finishes for construction. Additionally, it outlines the manufacture of bricks, including the preparation, moulding, drying, and burning processes to ensure strength and durability.