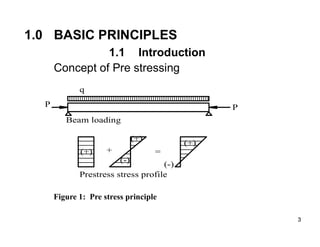

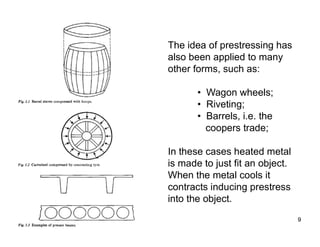

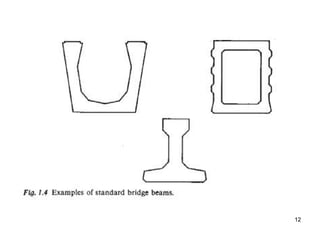

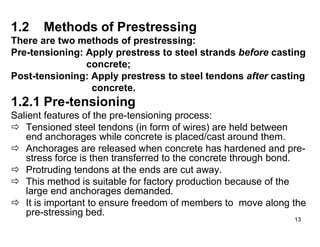

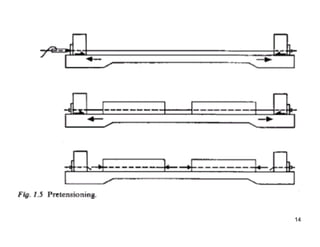

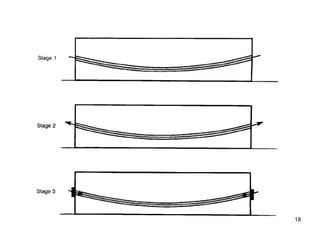

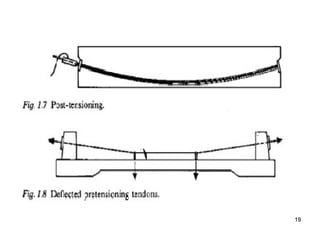

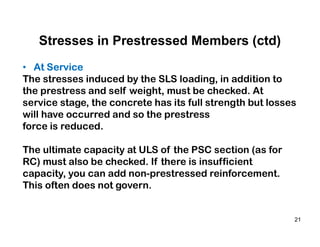

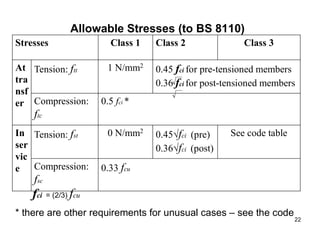

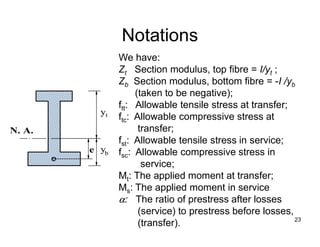

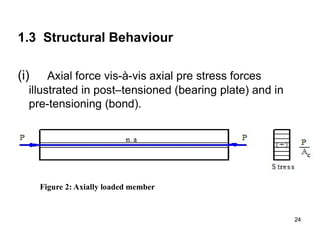

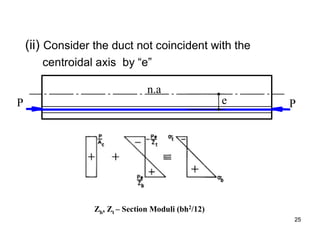

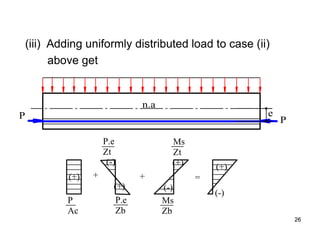

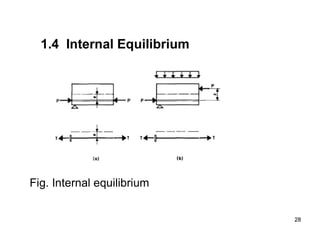

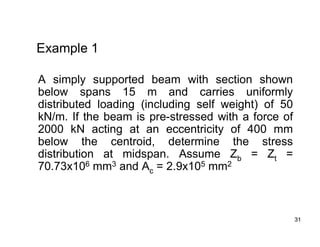

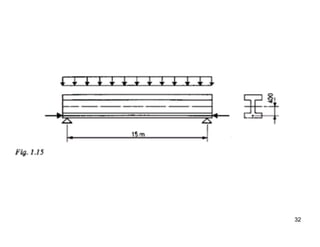

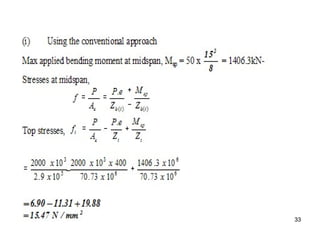

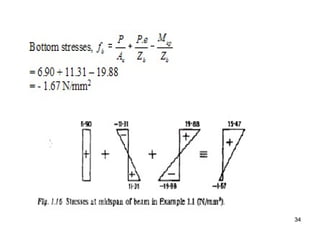

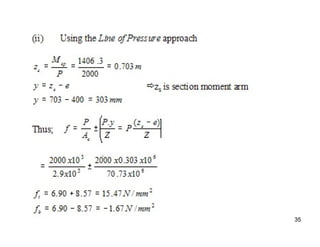

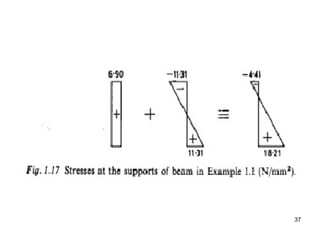

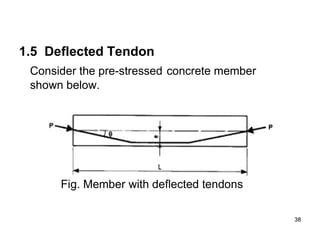

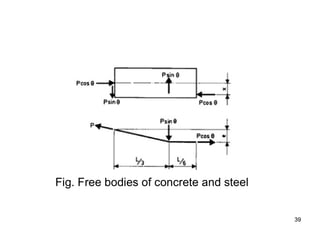

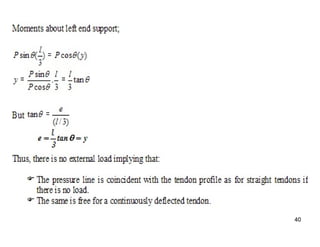

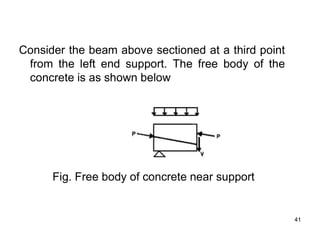

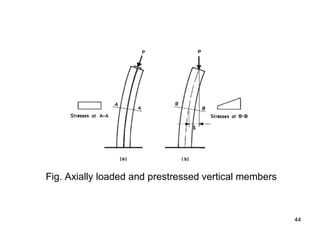

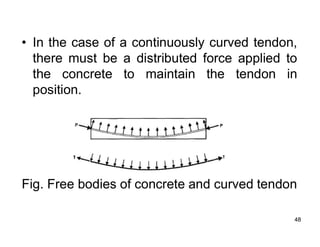

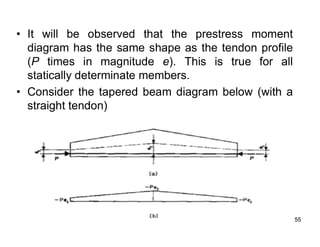

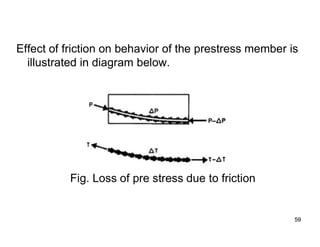

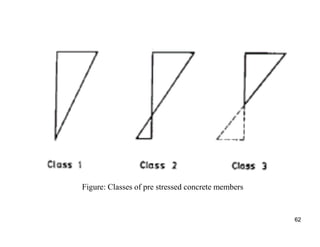

The document provides an overview of prestressed concrete design, including its historical development, basic principles, and primary applications such as bridges and floor systems. It outlines two main methods of prestressing—pre-tensioning and post-tensioning—along with their advantages and disadvantages, emphasizing the importance of quality control during construction. The document also discusses allowable stresses, internal equilibrium, and safety measures related to prestressed concrete structures.