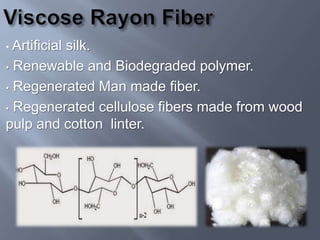

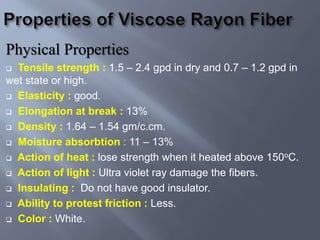

The document details the manufacturing process and properties of viscose rayon fiber, highlighting its physical and chemical characteristics such as strength, elasticity, and moisture absorption. The production involves steps like purification, steeping, mercerization, xanthation, and spinning, resulting in a versatile material used in various applications such as clothing and packaging. Additionally, viscose rayon is recognized for its silk-like texture and is commonly blended with other fibers for diverse uses.

![Mercerization

The cellulose is still contaminated with some hemicellulose. it is treated with 17-18%

NaOH solution at low temperatures for sometime, it swells up known as

mercerization. It involves partial destruction of intermolecular bonds, penetration of

NaOH in he swollen amorphous regions of the cellulose, where they are held by

hydrogen bonding and sodium cellulose is formed.

Rcell - OH + NaOH ---> [Rcell - OH.NaOH]

Ageing

cellulose undergoes pre-ripening in presence of air. chemical degradation process and

involves :

•Oxidation of primary -OH group to aldehyde or carboxylic acid group.

•Oxidation of secondary -OH group to ketonic group , extending up to carboxylic acids

•Rupture of the terminal oxide ring and polymer chains.

Xanthation

alkali cellulose is separated and taken in a horizontal drum, where it is treated with

60% carbon disulphide. The drum is rotated during the addition of CS2 and temperature

is maintained at about 20oC. The product, sodium cellulose xanthate swells up slowly

and a deep orange coloured gelatinous mass is obtained in 3-4 hours.

[C6H5O5]n + NaOH ---> [C6H10O5.NaOH]n + CS2 ---> (C6H9O4)3.OH.OCS2Na](https://image.slidesharecdn.com/neeturayonfiber-201007122148/85/Viscose-Rayon-Fiber-8-320.jpg)