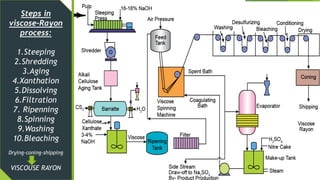

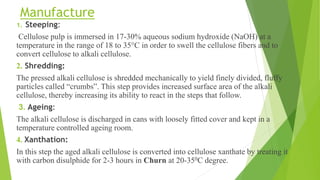

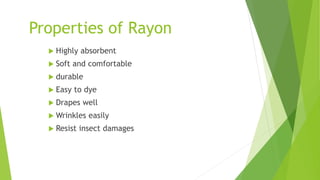

The presentation provides an overview of rayon, a manufactured regenerated cellulose fiber, its history, and the viscose-rayon production process. Key steps in the process include steeping, shredding, xanthation, and spinning, resulting in a durable and versatile fabric used in various clothing items. The future of rayon looks promising due to increasing demand and advancements in technology, leading to a trend toward blended fabrics.