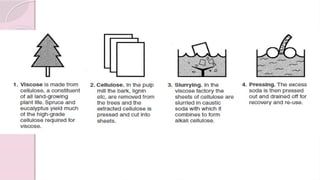

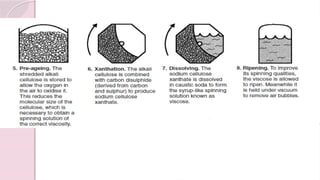

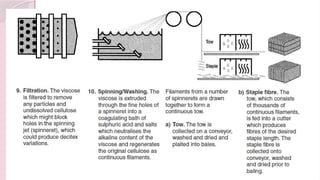

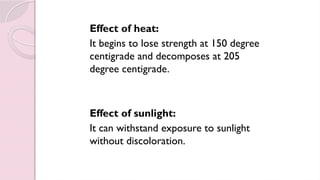

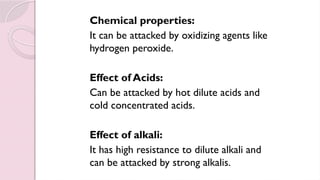

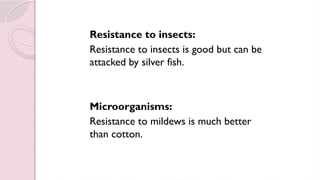

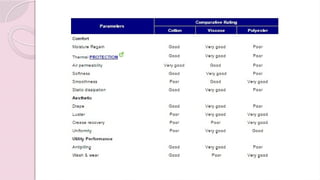

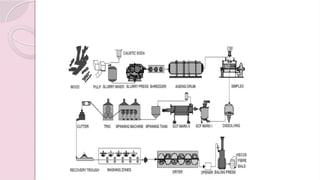

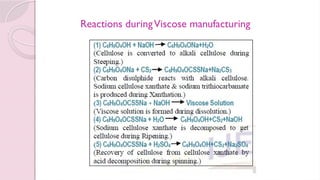

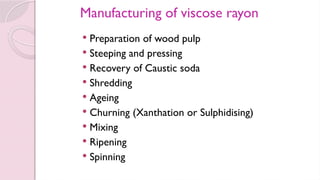

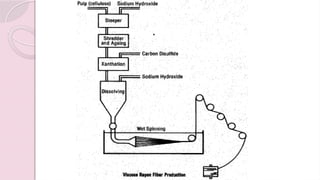

Viscose rayon is a manmade fiber created from regenerated cellulose, initially discovered in 1891, that is similar in properties to cotton and flax. The manufacturing process involves multiple steps including preparing wood pulp, xanthation, and spinning the viscose solution to produce fiber, with applications in apparel and home furnishings. It offers qualities such as a silk-like aesthetic, good feel, and specific chemical resistance, making it a versatile textile option.

![Empirical formulae of cellulose = (C6H10O5)n

Steeping:

(C6H10O5)n + NaOH = [C6H9O4-ONa]n

(Soda cellulose)](https://image.slidesharecdn.com/11-viscoserayon-250106170001-acd35c28/85/11-Viscose-Rayon-properties-and-structure-pptx-11-320.jpg)