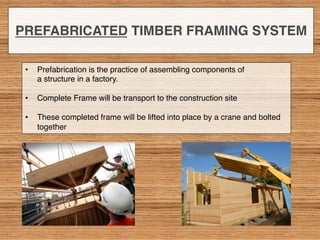

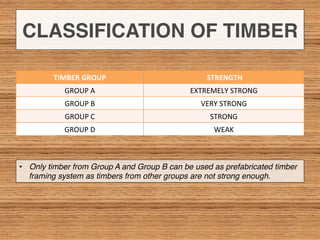

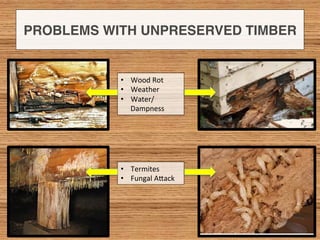

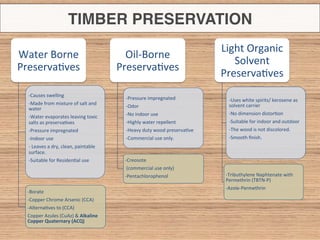

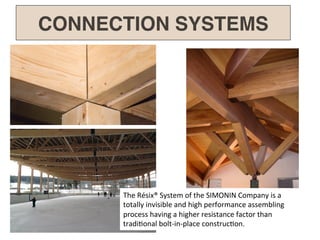

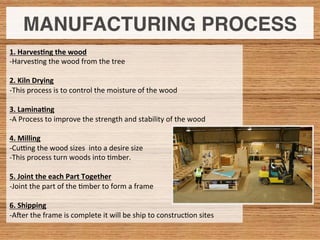

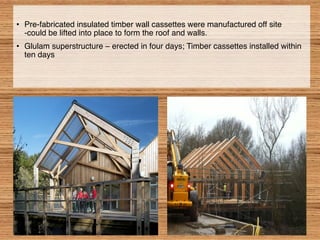

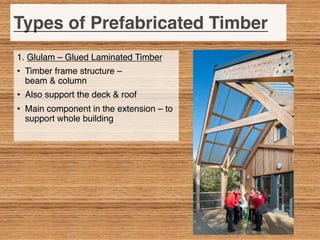

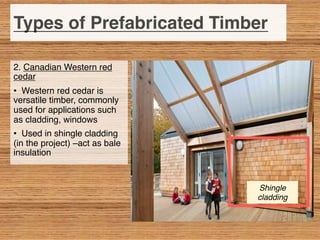

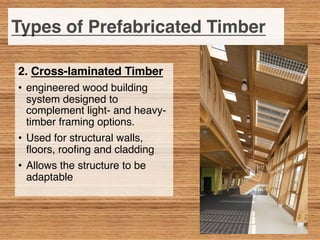

This document discusses prefabricated timber framing systems. It begins by introducing timber frames and how they transfer loads. It then discusses prefabricated timber framing, which involves assembling frames off-site and transporting them for installation. The document covers timber types, structural elements, connection systems, manufacturing processes, case studies, and advantages/disadvantages of prefabricated timber framing. It concludes by promoting the sustainable and structural benefits of using more timber in construction.