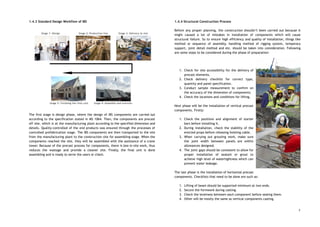

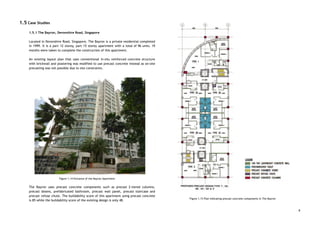

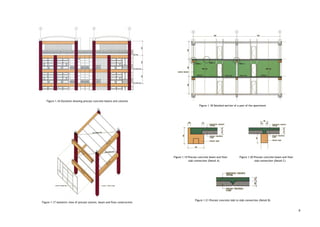

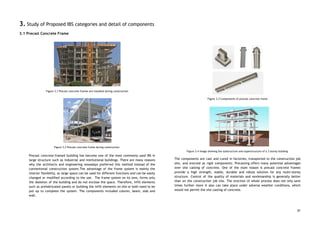

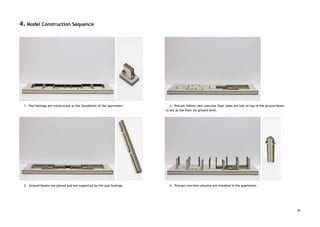

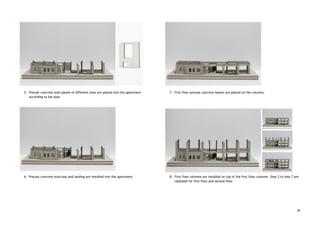

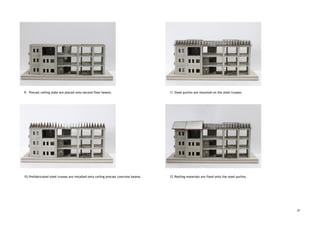

This document provides an overview of Industrialized Building Systems (IBS) with a focus on precast concrete systems. It defines IBS and discusses the key types, including precast concrete, steel framing, formwork, blockwork, timber framing, and innovative systems. The advantages of IBS are faster construction, higher quality, and lower cost. Potential defects in precast concrete like water leakage and cracking are also outlined. The document presents the standard design and construction workflows for IBS and provides case studies of two apartment buildings in Singapore that utilized precast concrete systems.

![Reference list:

1. Industrialised building system (IBS). (2017, September 27). Retrieved October 08, 2017, from

https://en.wikipedia.org/wiki/Industrialised_building_system_(IBS)

2. 마 이환 Follow. (2014, July 04). Group Assignment:IBS System. Retrieved October 08, 2017,

from https://www.slideshare.net/x3HwaN/group-assignmentibs-system

3. Concrete masonry unit. (2017, September 30). Retrieved October 08, 2017, from

https://en.wikipedia.org/wiki/Concrete_masonry_unit

4. Ibs Complete. (n.d.). Retrieved October 08, 2017, from

https://www.scribd.com/doc/21794505/Ibs-Complete

5. Concrete Frame Construction | Concrete Frame Structures. (n.d.). Retrieved October 08, 2017,

from http://www.understandconstruction.com/concrete-frame-structures.html

6. History Of Ibs In Malaysia Construction Essay. (n.d.). Retrieved October 08, 2017, from

https://essays.pw/essay/history-of-ibs-in-malaysia-construction-essay-68039

7. Bhd, I. M. (1970, January 01). IBS Modular. Retrieved October 08, 2017, from

http://ibsmodular.blogspot.my/

8. Abhishek Gupta, Working Follow. (2015, April 03). PreCast Construction. Retrieved October 08,

2017, from https://www.slideshare.net/shekhu001/precast-construction

9. Precast Concrete Frame Buildings Design Guide. (n.d.). Retrieved October 08, 2017, from

https://www.scribd.com/doc/51059215/Precast-Concrete-Frame-Buildings-Design-Guide

10. Experimental study of a new beam-to-column connection for precast concrete frames under

reversal cyclic loading. (n.d.). Retrieved October 08, 2017, from

http://journals.sagepub.com/doi/abs/10.1177/1369433216630122

11. Precast Wall Connections, Precast Walls, Precast Frames. (n.d.). Retrieved October 08, 2017,

from

http://www.oreillyconcrete.com/products/precast-walls/precast-wall-connection-details/#prettyPh

oto[postimages]/5/

12. (n.d.). Retrieved October 08, 2017, from http://www.swiftseal.com/construction%20joints.html

13. Industrialised building systems in Malaysia. (2006). Malaysia: CIDB.

34](https://image.slidesharecdn.com/btechp1report-171217061436/85/Industrialised-Building-Solution-36-320.jpg)