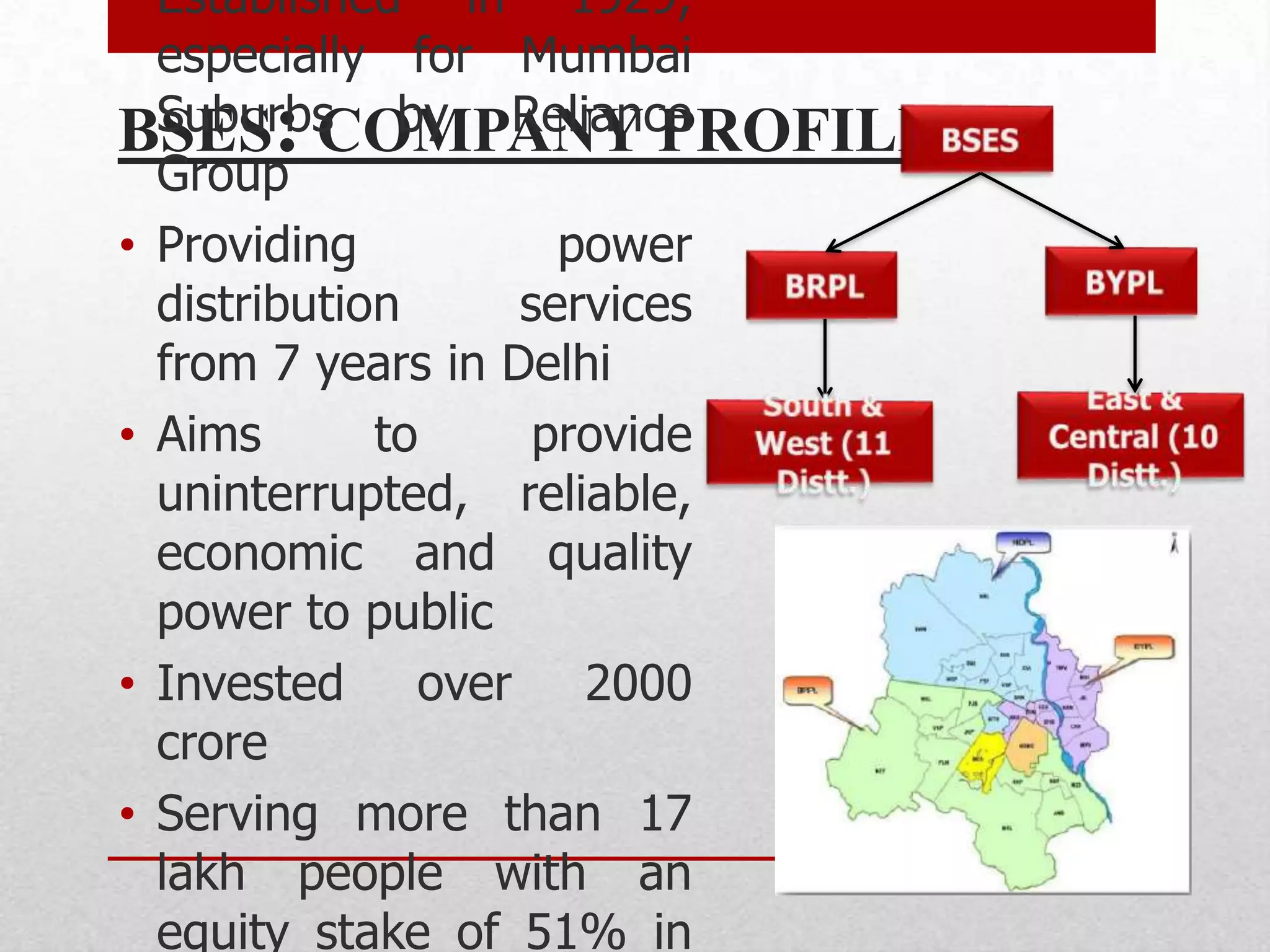

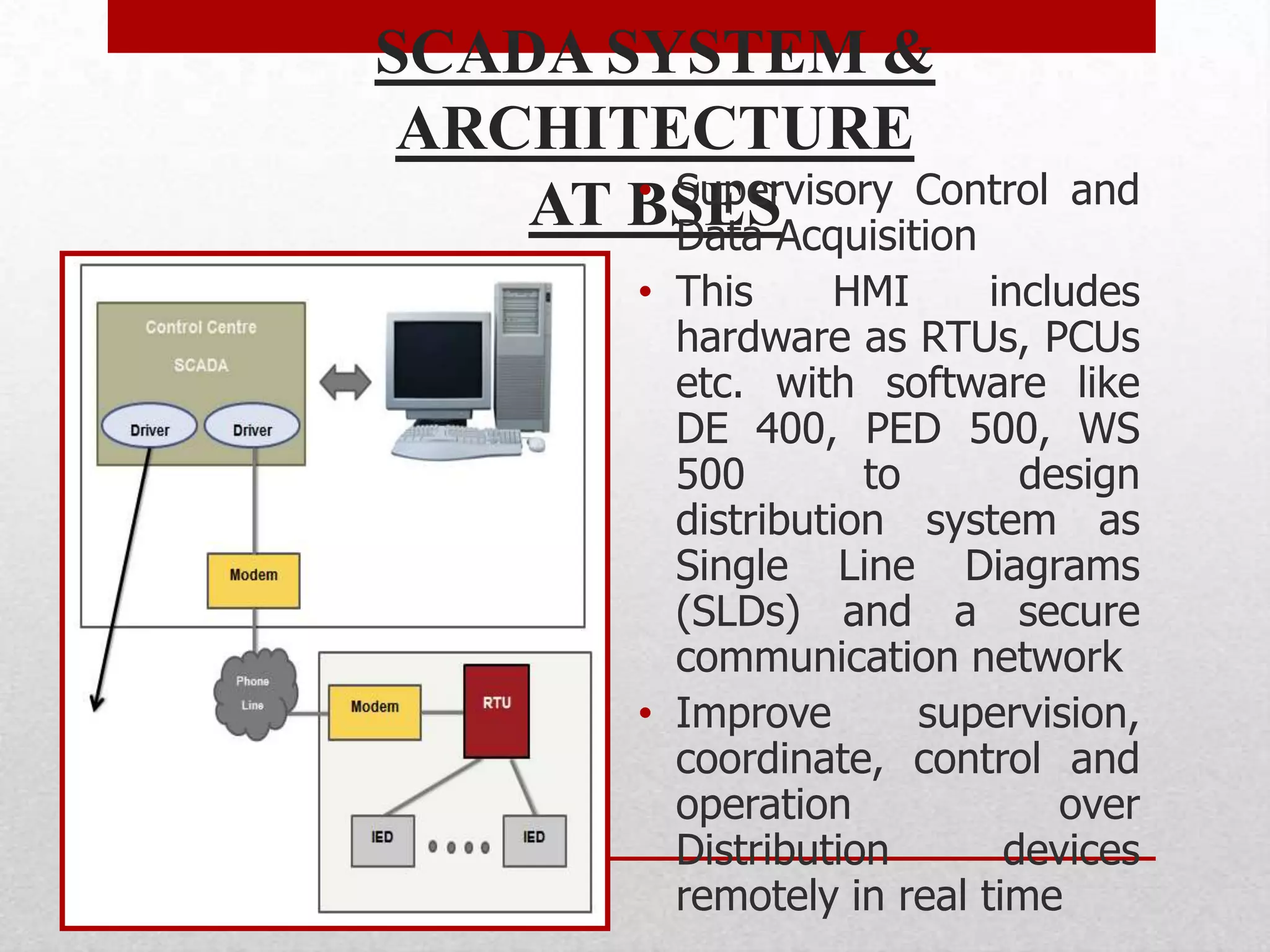

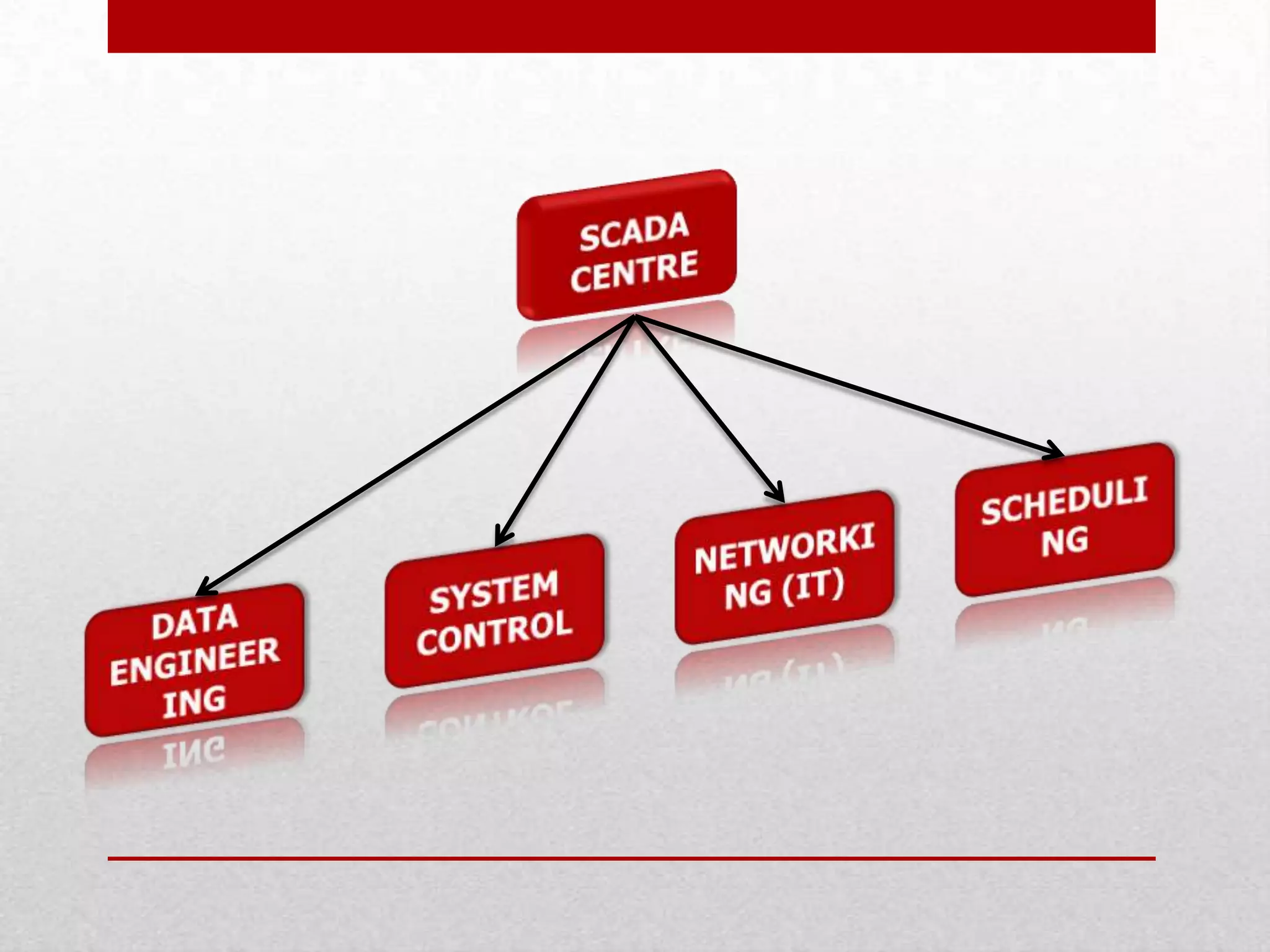

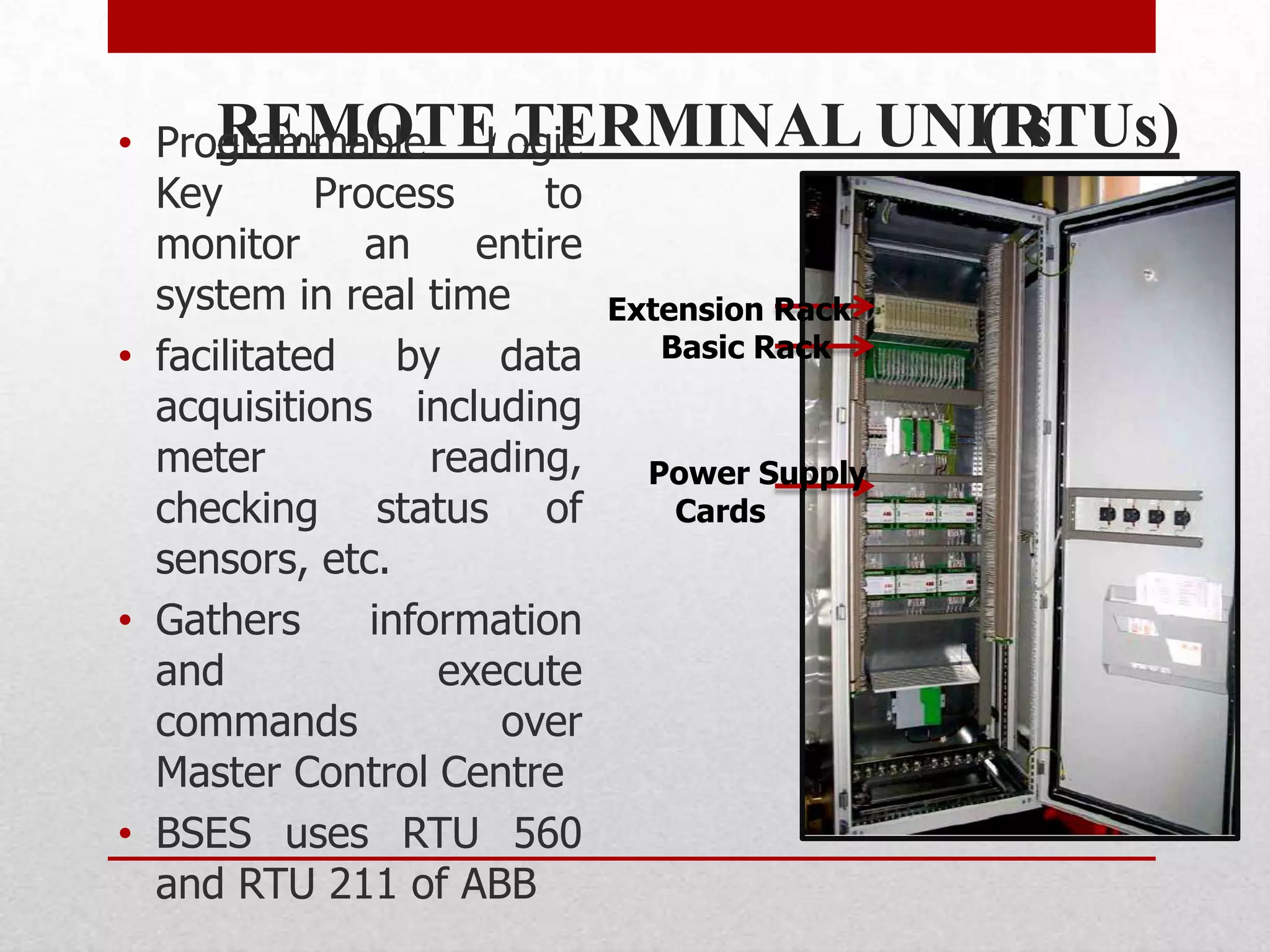

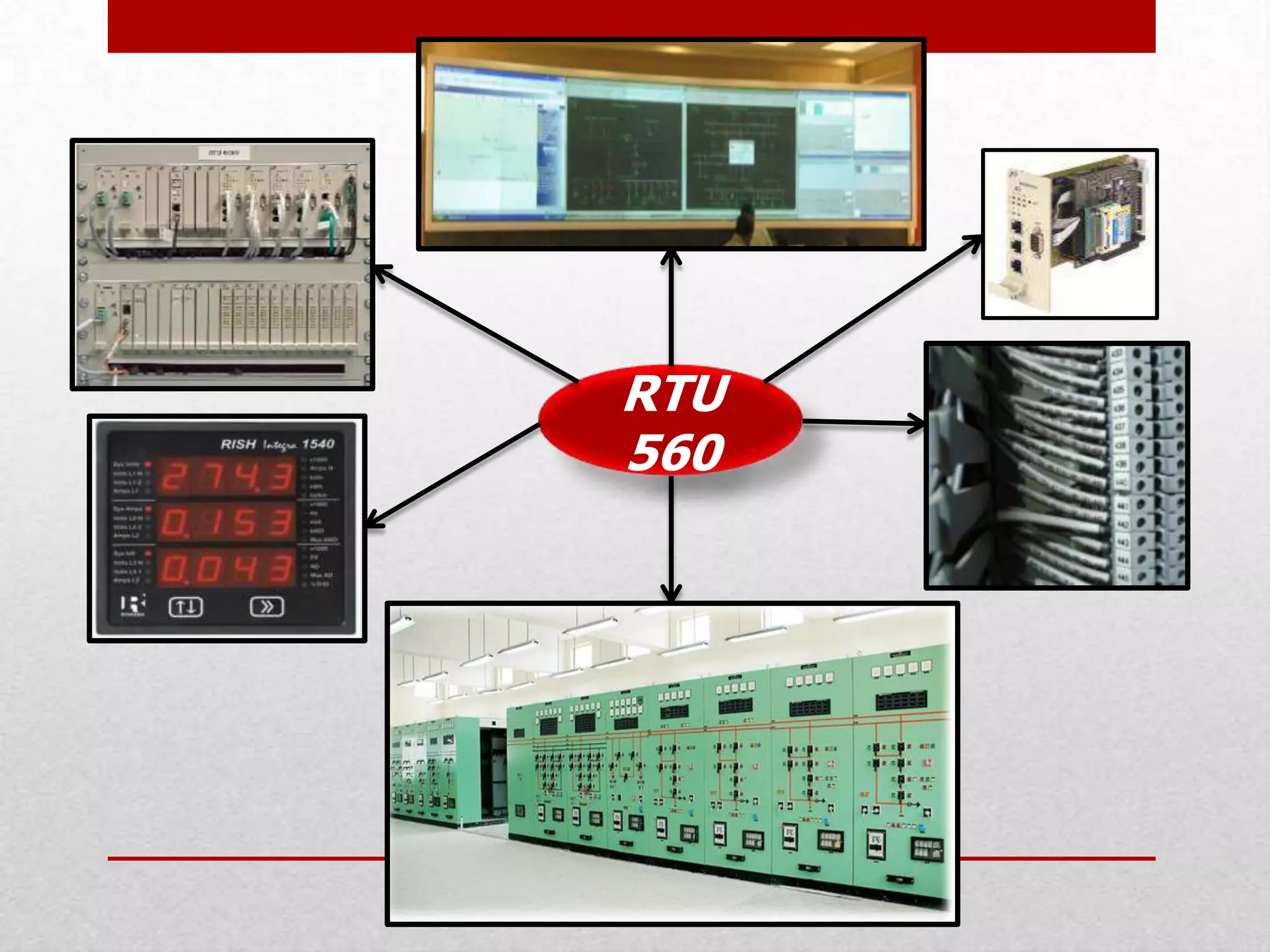

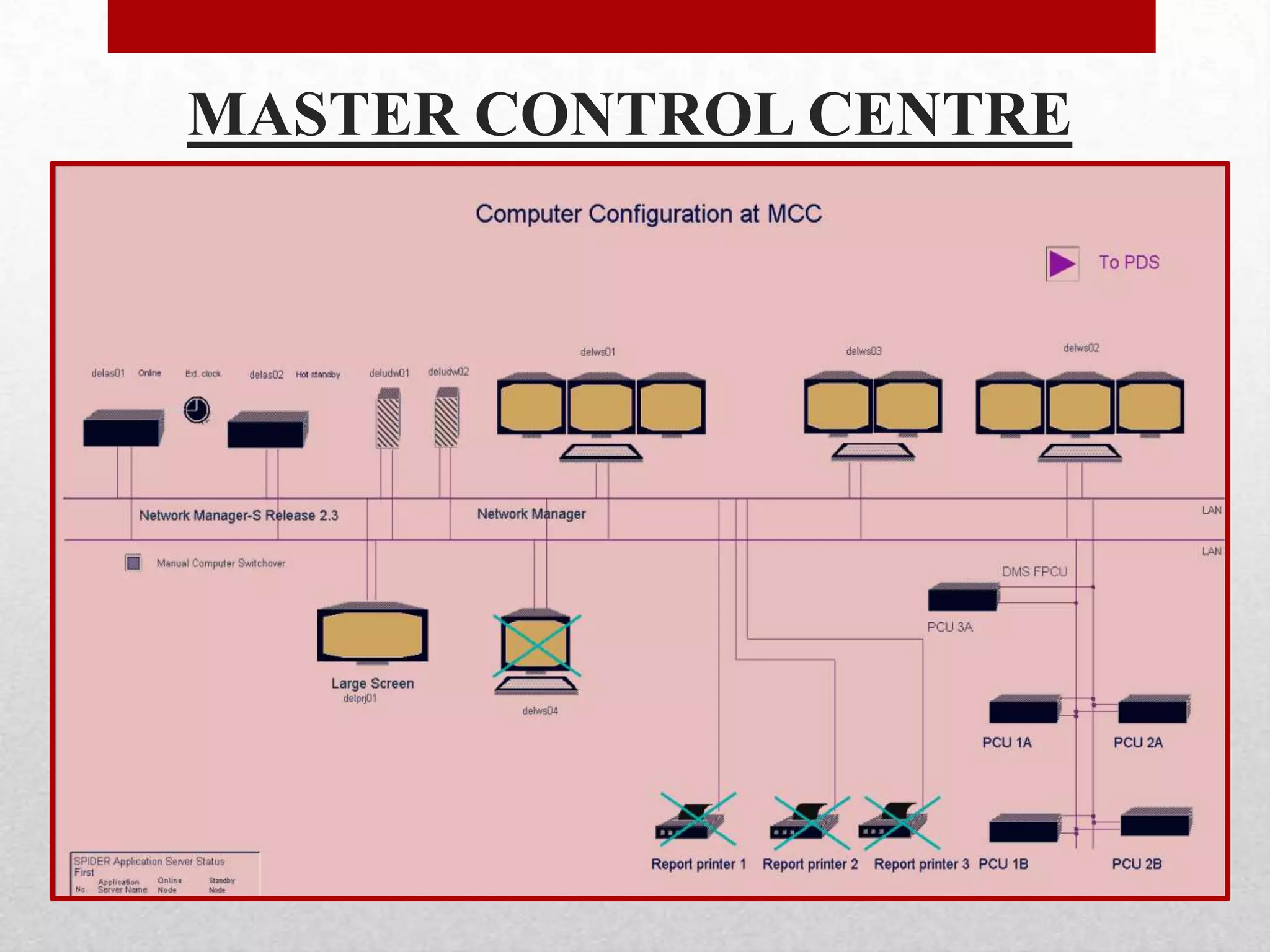

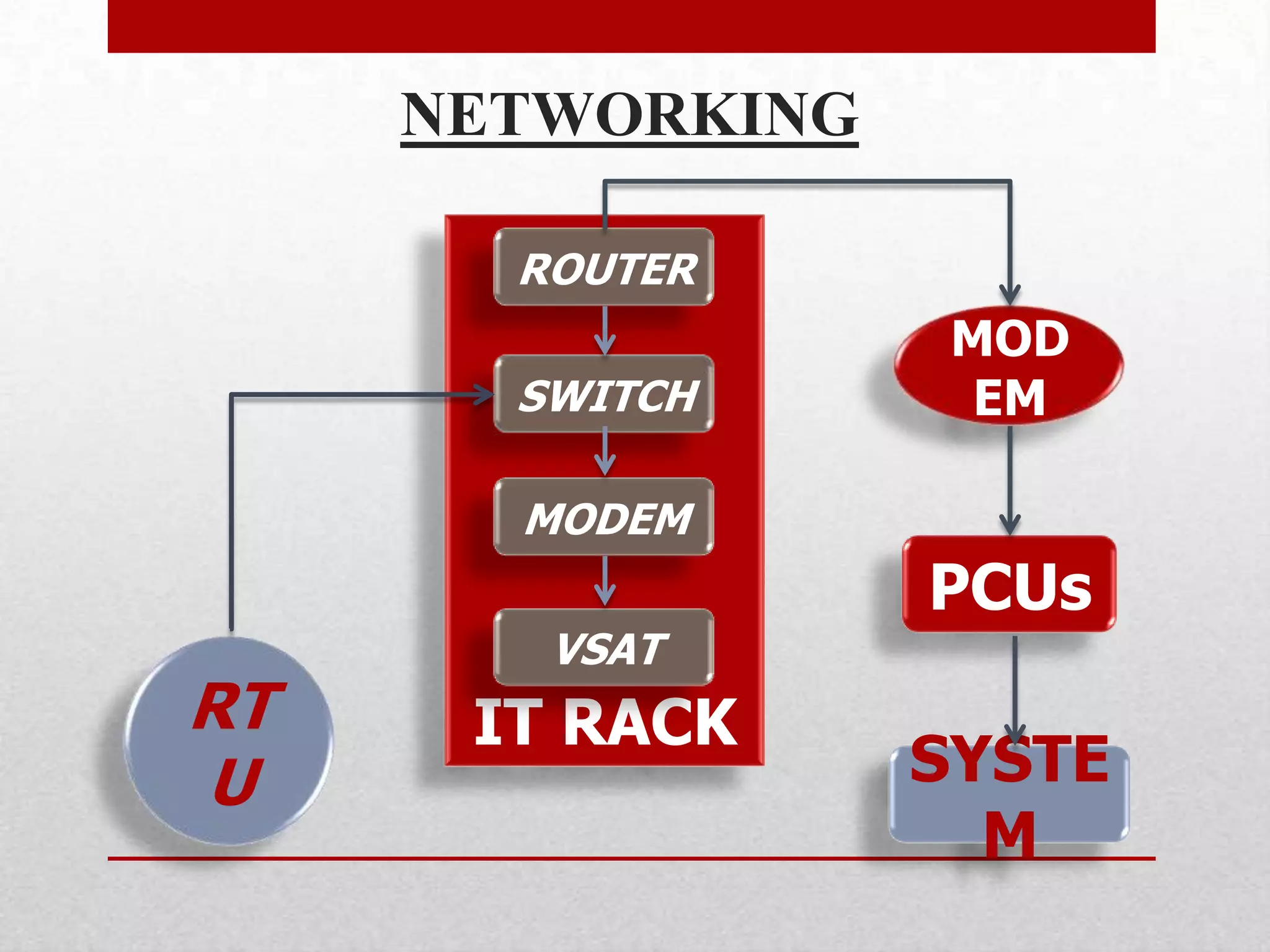

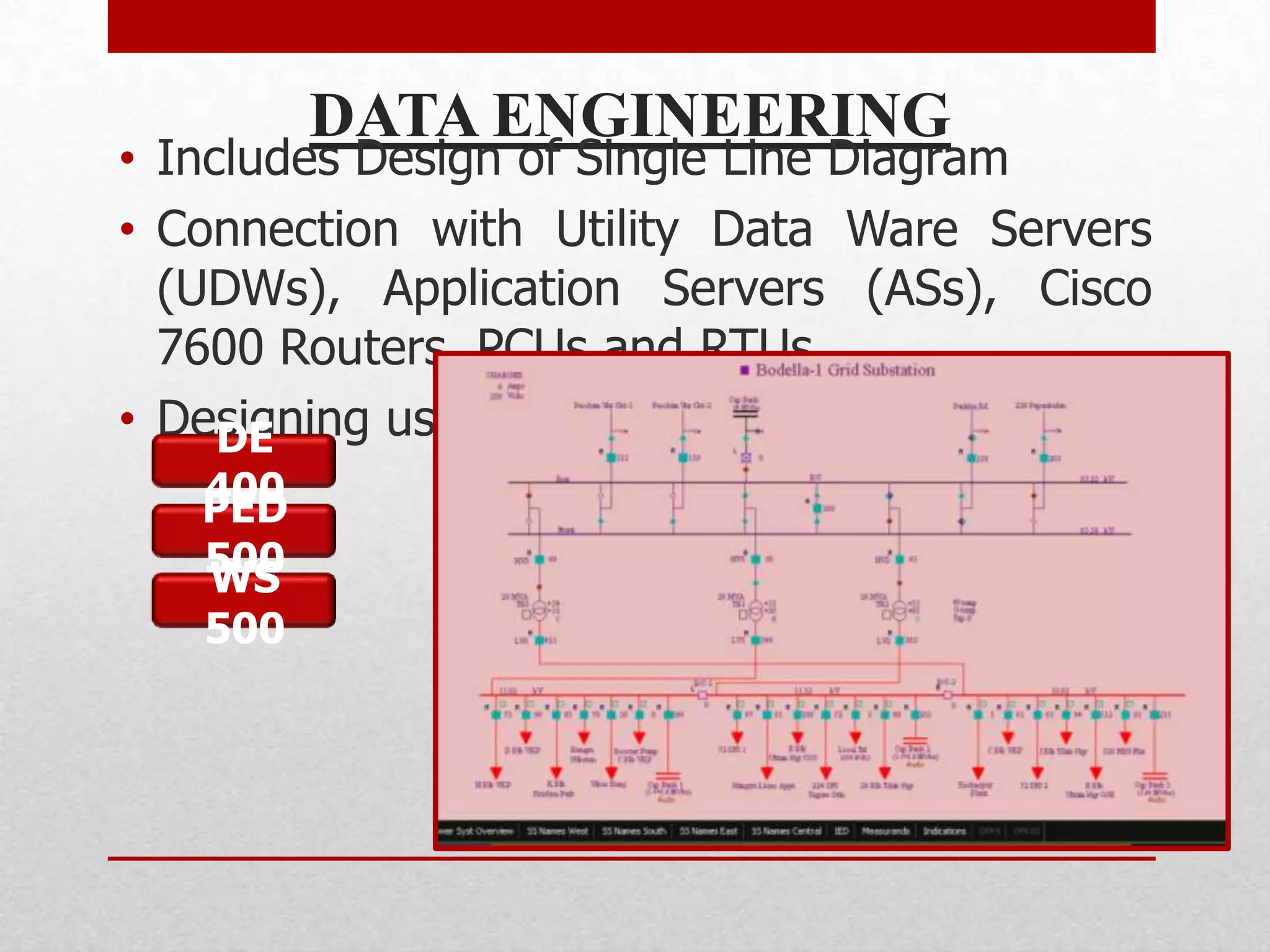

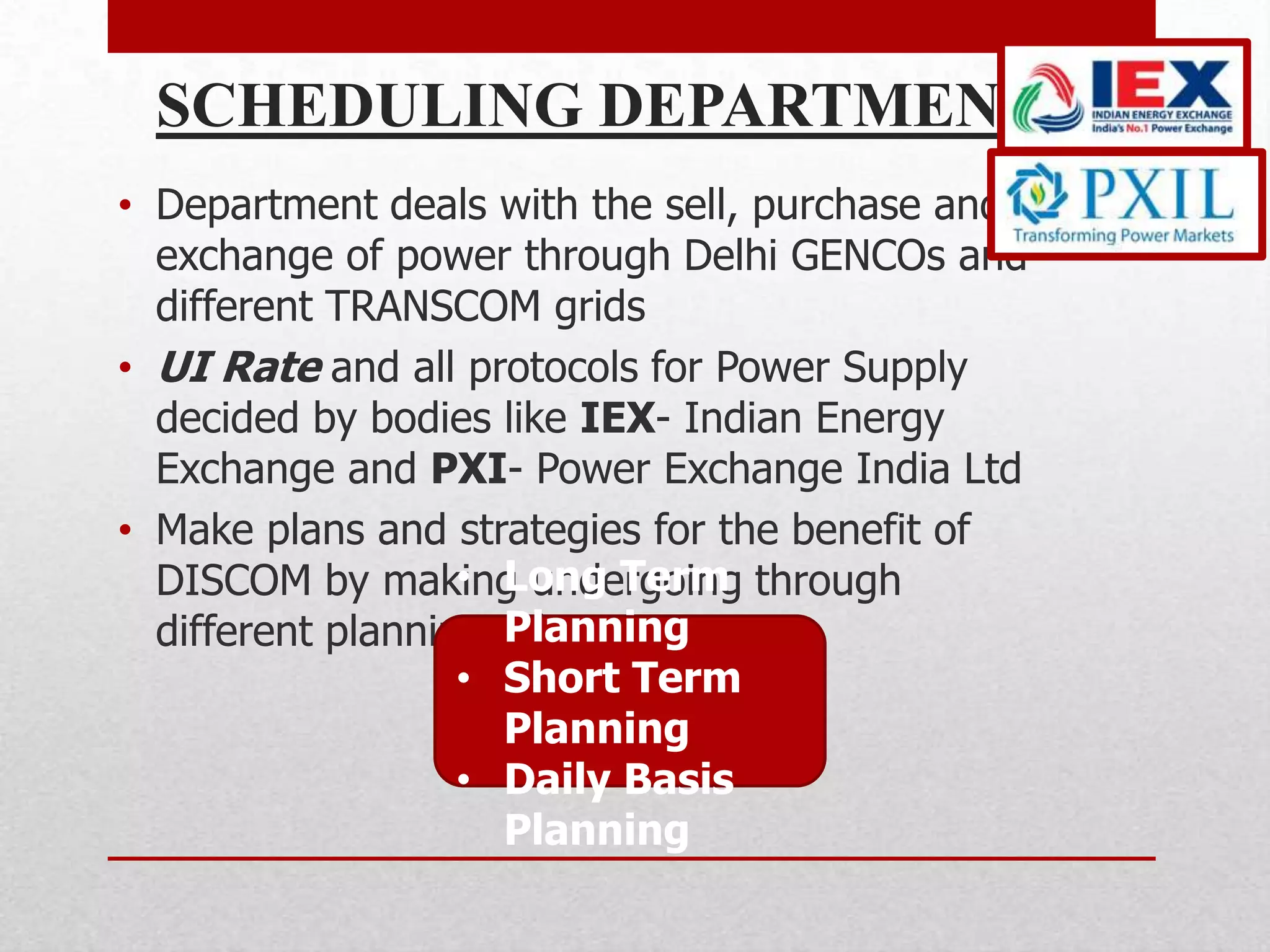

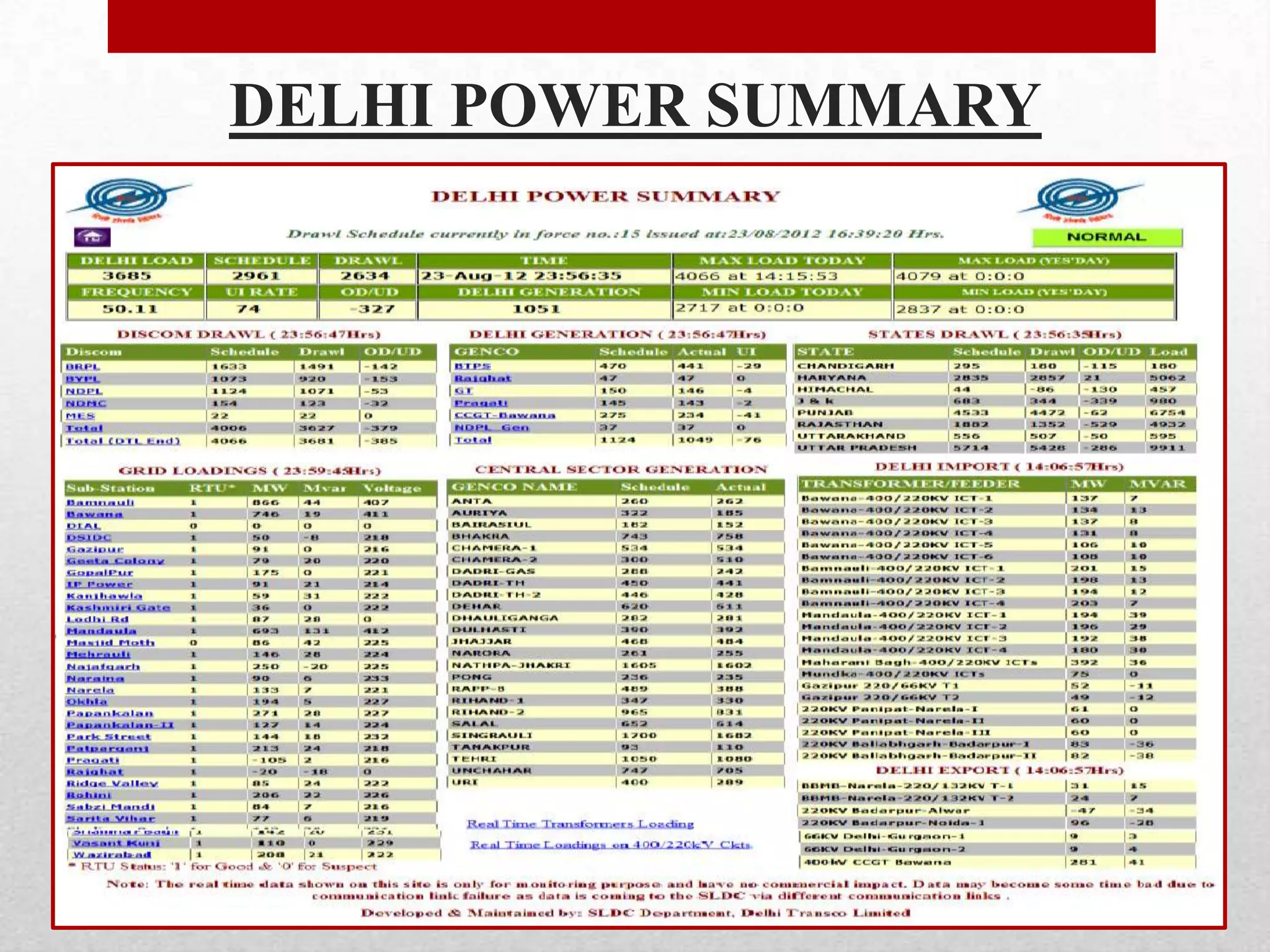

This document provides an overview of a training seminar on substation automation. It discusses BSES company profile, SCADA system architecture including hardware components like RTUs and PCUs and software like DE 400 and PED 500. It also covers need for SCADA automation to improve system monitoring, reduce power theft and fault restoration times. Key components discussed are remote terminal units, master control centre, networking, data engineering and scheduling department functions.