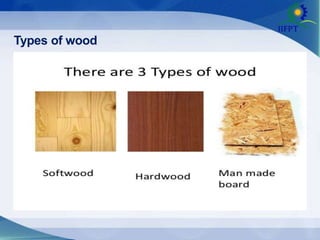

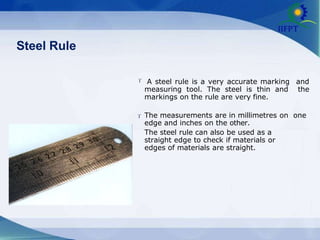

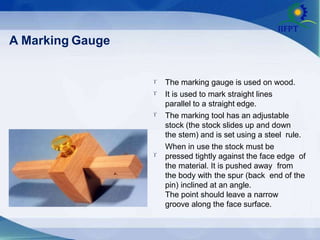

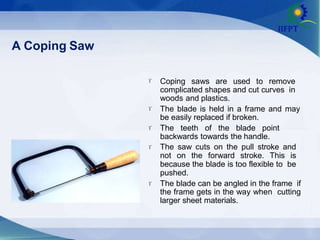

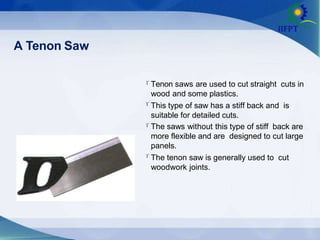

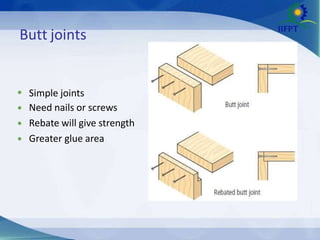

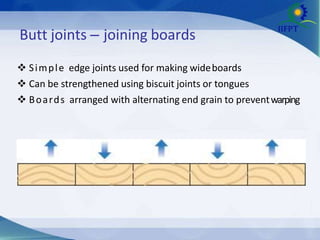

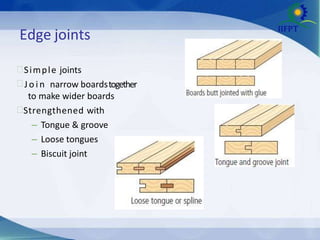

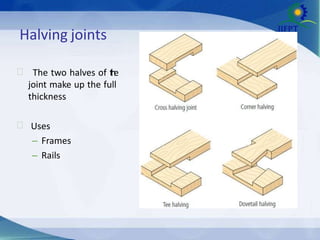

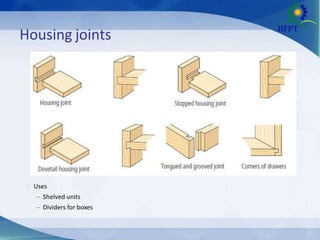

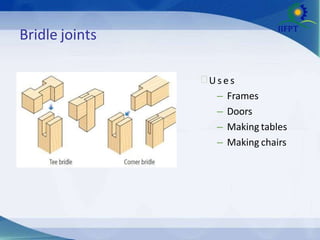

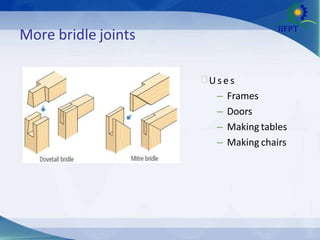

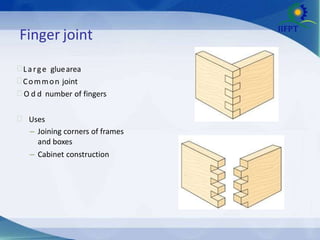

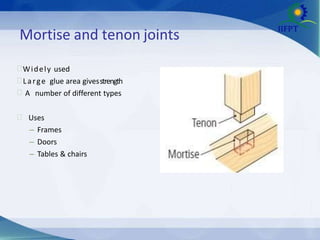

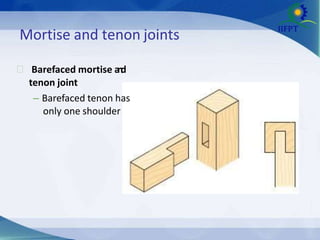

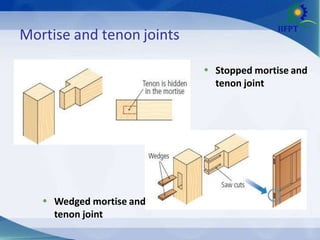

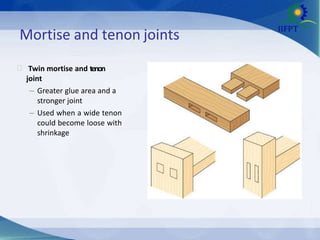

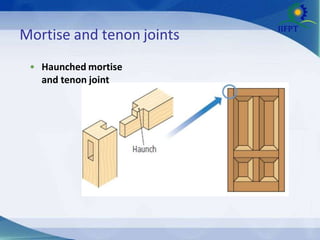

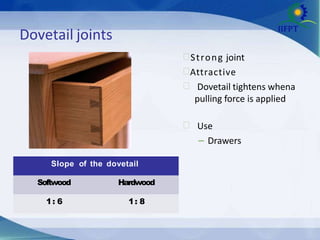

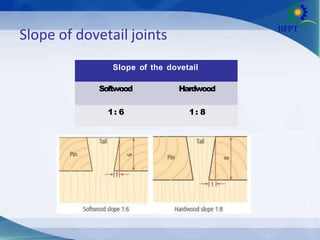

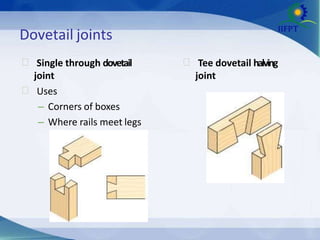

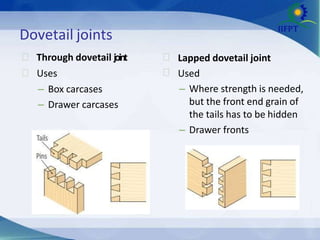

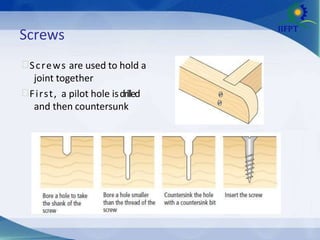

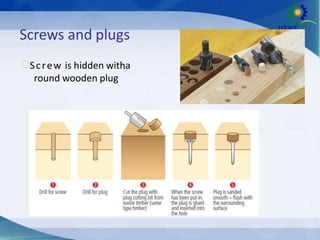

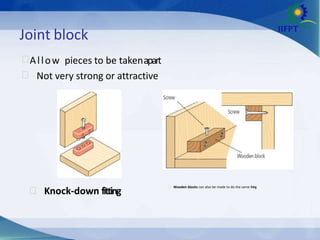

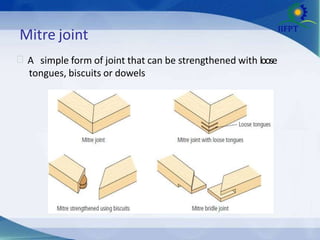

This document discusses various carpentry tools, wood types, and wood joints. It provides details on try squares, steel rules, marking gauges, coping saws, tenon saws, and wood planes. It also describes manufactured wood materials like MDF and plywood. Finally, it examines common wood joints like butt joints, edge joints, halving joints, housing joints, bridle joints, finger joints, mortise and tenon joints, dovetail joints, dowel joints, and mitre joints.