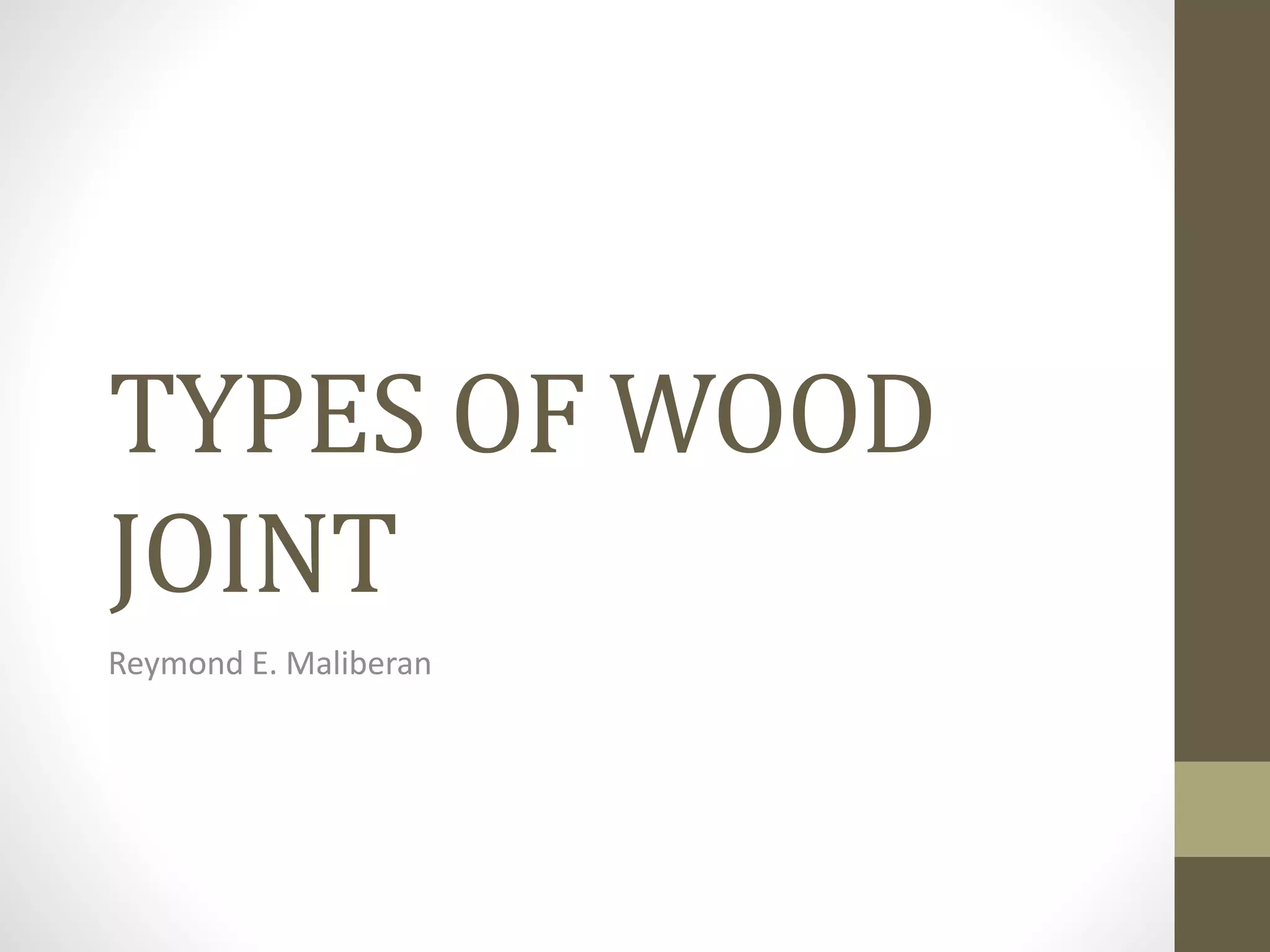

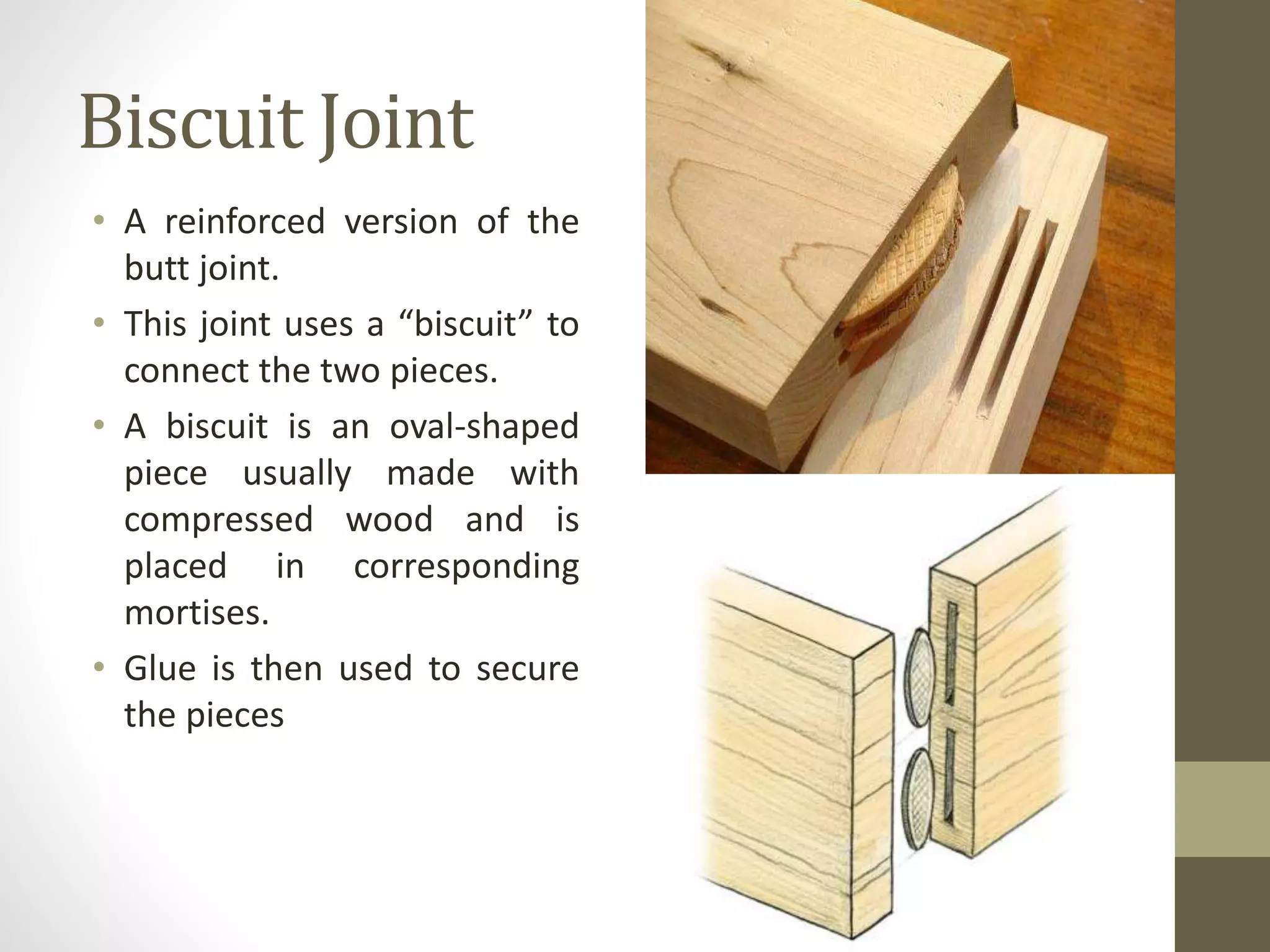

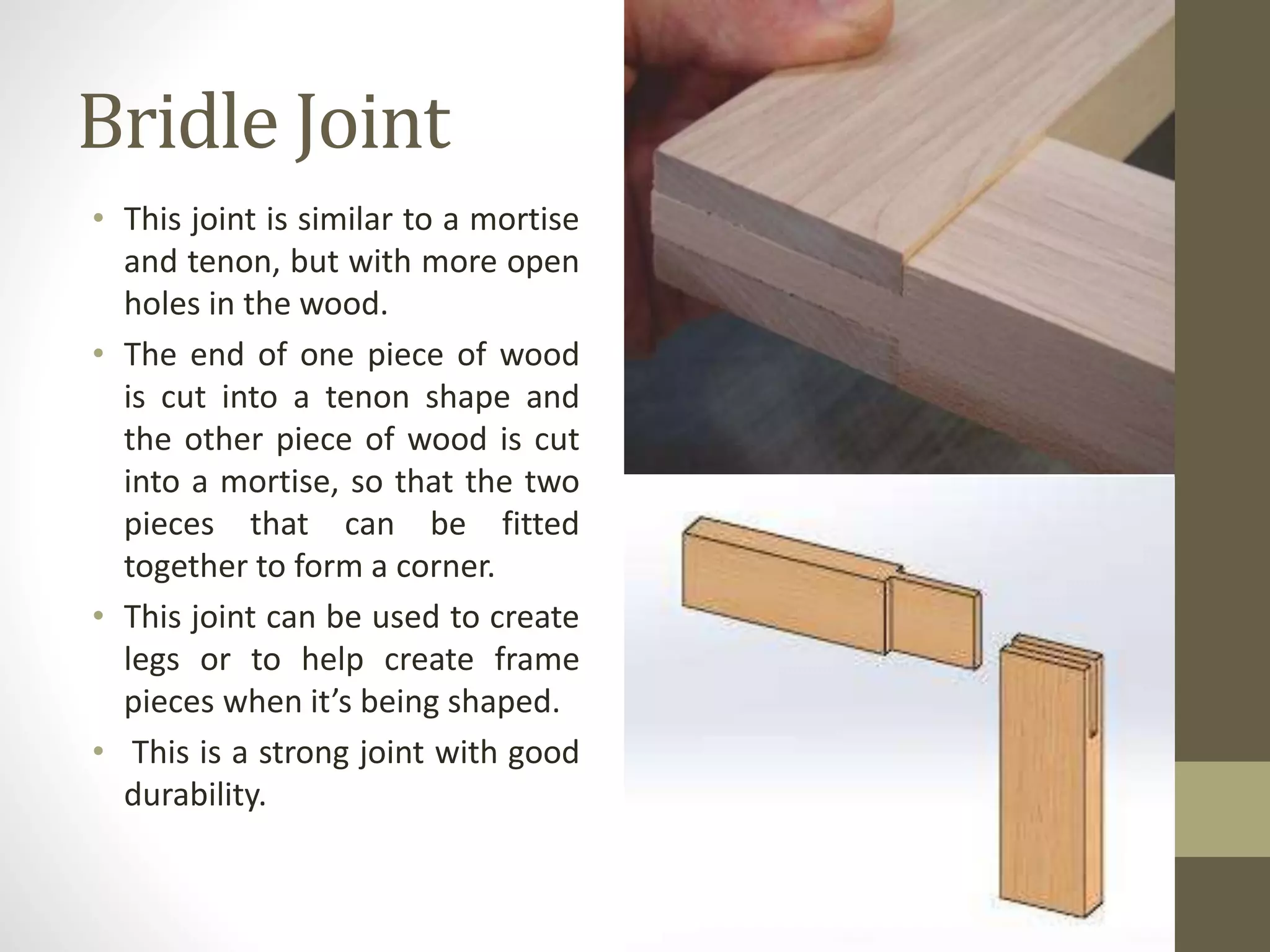

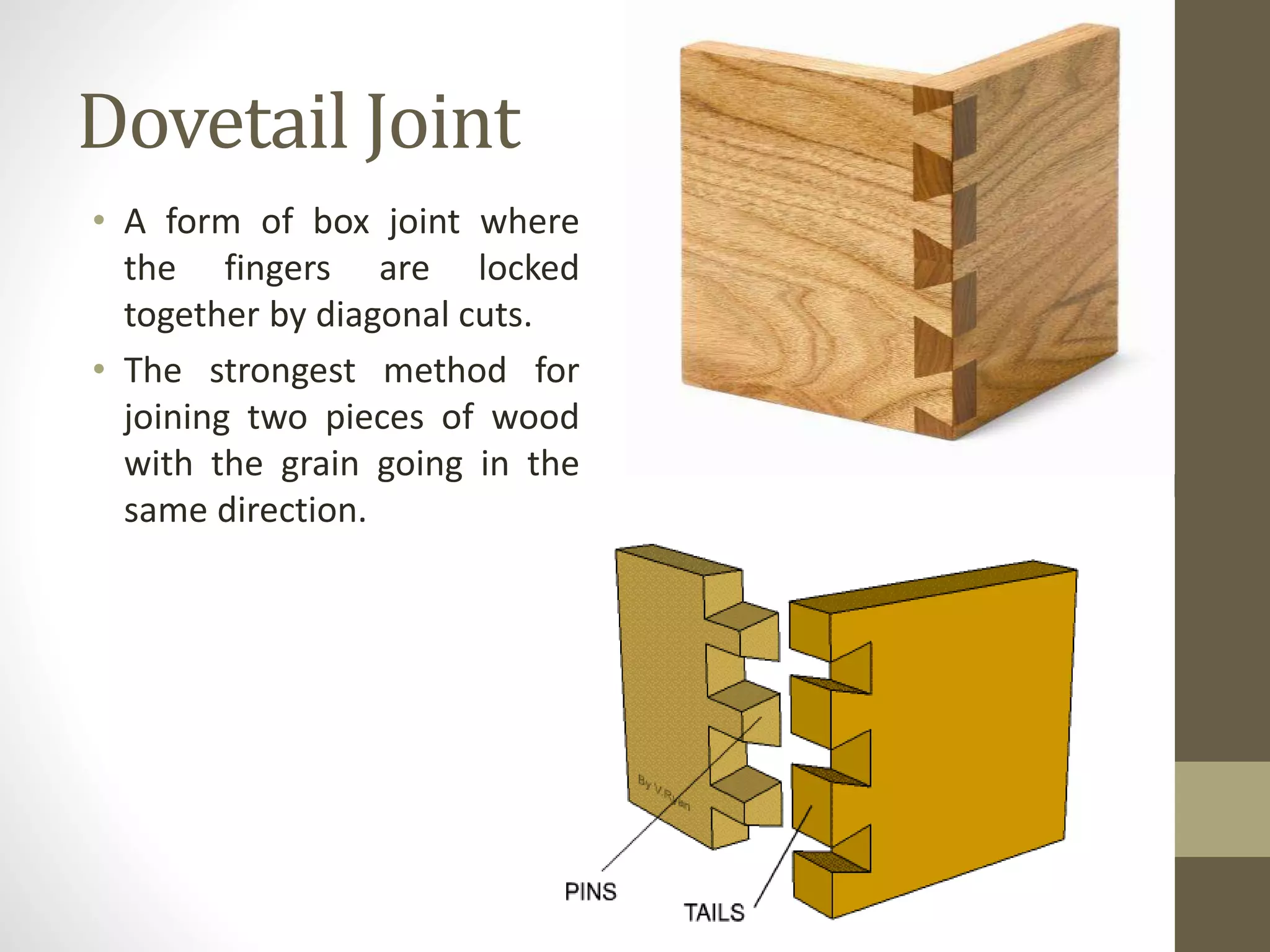

There are many types of wood joints that can be used for different purposes. Some key wood joints include butt joints which simply join the ends of two pieces together, biscuit joints which use an oval piece to reinforce a butt joint, and mortise and tenon joints which are very strong and join two pieces at a 90 degree angle. Other common joints include dovetail joints which are the strongest for joining wood end grain to end grain, finger joints which are similar but with straight pins, and tongue and groove joints which provide a strong connection along the long edge of boards. Each joint has advantages for strength, durability and application, though some require more time and skill to execute.