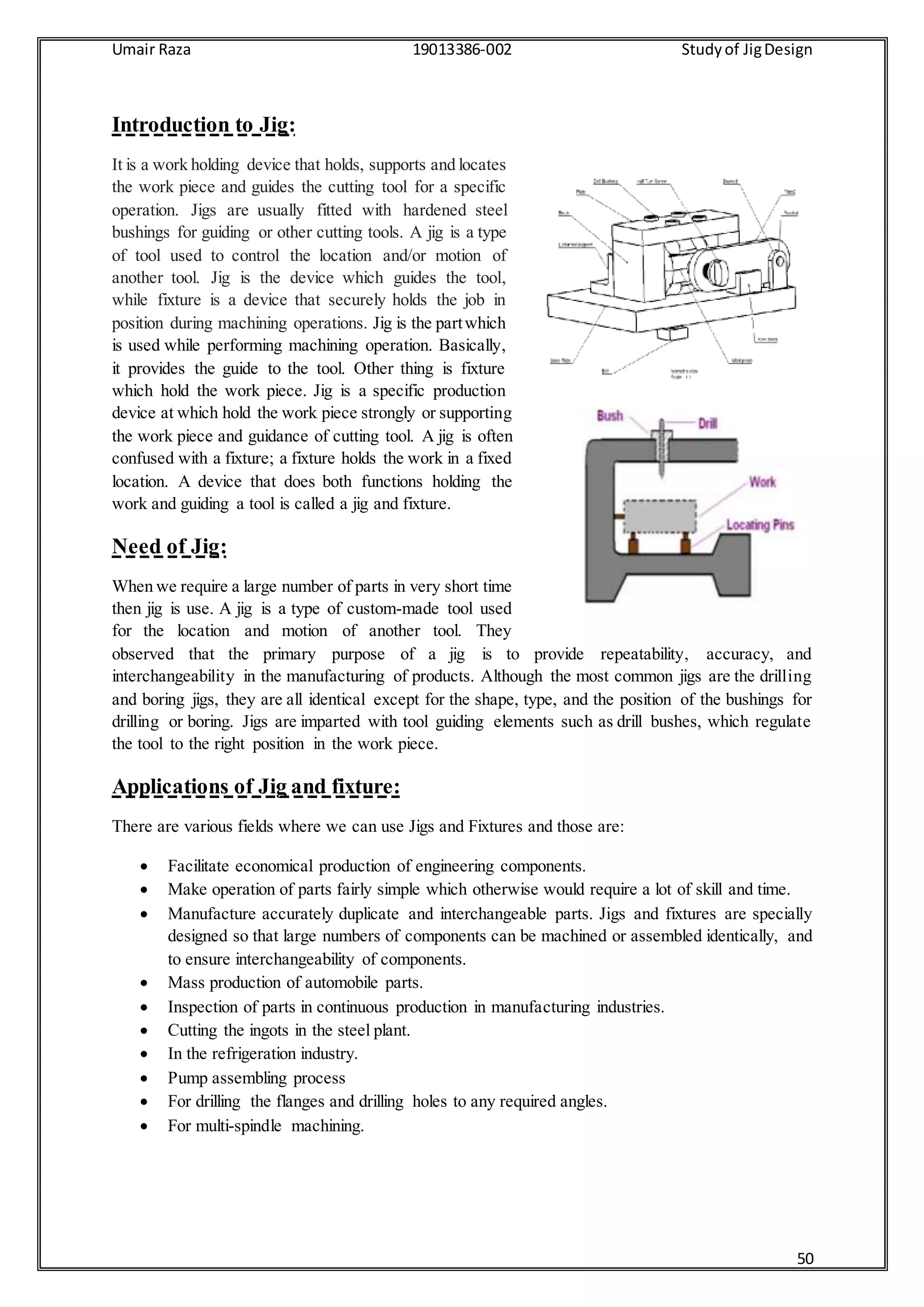

A jig is a work holding device that locates and guides a cutting tool during machining operations to provide repeatable accuracy. It differs from a fixture which solely holds the workpiece. The document discusses the need for jigs in mass production situations. It provides examples of jig applications and purposes, which include facilitating economical production and interchangeability. The document compares an old jig design to a new proposed design, noting advantages of the new design include easier workpiece binding and a more organized drilling direction. It concludes that jigs are an essential manufacturing element that can increase production rates and reduce costs through consistent part accuracy.