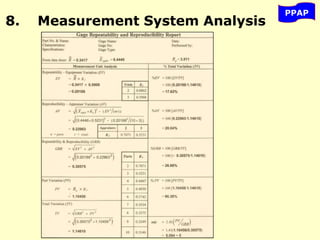

Here are the key steps to conduct a variable MSA:

1. Select a part/product with known measurements.

2. Select operators who will use the measurement system.

3. Have operators measure the part multiple times.

4. Analyze the data using one of the methods:

- Bias study to determine if the measurement system is accurate.

- Linearity study to determine if measurements are proportional to actual size.

- Stability study to determine if measurements drift over time.

- Repeatability & reproducibility study to determine precision between and within operators.

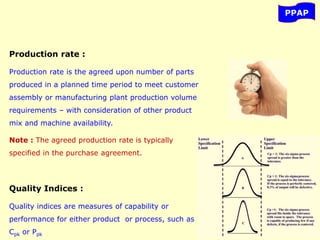

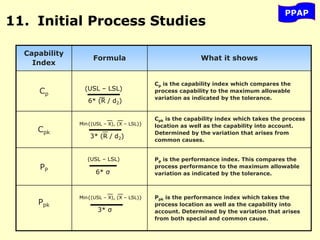

5. Compare results to customer specifications for capability. Ensure Cp, Cpk are greater than 1.33.

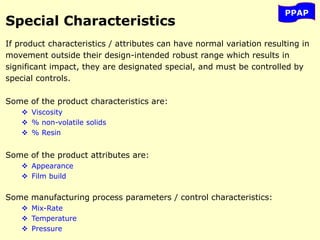

![PPAP

Customer Plant Connection

Customer plant connection is a shared

responsibility between the organization

supplying bulk material and the customer.

This connection defines the interaction of

specific customer plant processing steps

with special characteristics and final

product attributes of the bulk material.

The interaction is especially significant

when bulk materials undergo chemical or

physical transformations.

[Example: wet can of paint to cured paint

film]](https://image.slidesharecdn.com/ppap-230827172349-3af357dd/85/PPAP-ppt-83-320.jpg)