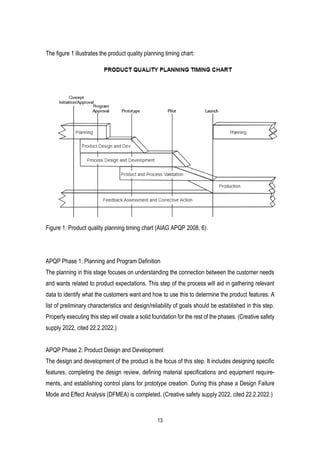

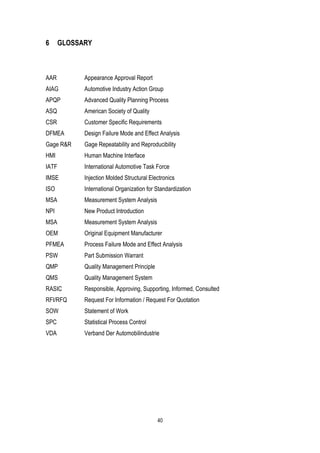

This document is a master's thesis submitted by Kimmo Määttä to Oulu University of Applied Sciences. The thesis investigates integrating the Production Part Approval Process (PPAP) framework into the product development process at TactoTek Oy. TactoTek supplies injection molded structural electronics parts to the automotive industry, where PPAP is commonly used. The thesis aims to identify which areas of TactoTek's quality management system are affected by PPAP, how PPAP affects TactoTek's processes and procedures, and what improvements are needed for TactoTek's QMS to fulfill PPAP requirements. Gap analysis and cross-functional teams are used to analyze TactoTek's current