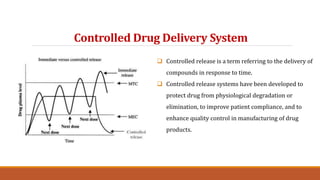

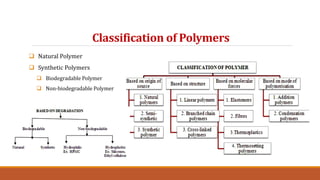

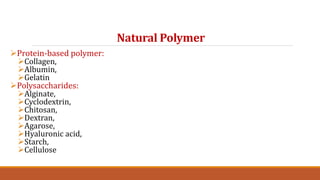

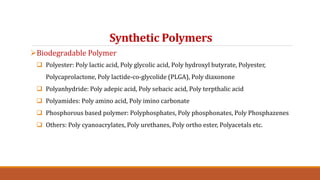

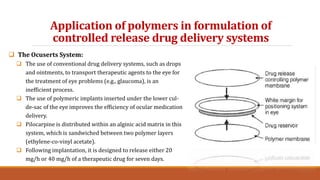

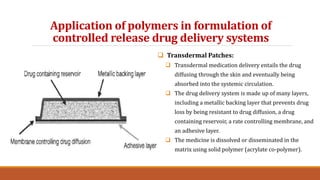

Polymers are large molecules composed of repeating structural units and can be either natural or synthetic, biodegradable or non-biodegradable. They are widely used in controlled release drug delivery systems due to their ability to control drug release rates and provide advantages like improved patient compliance. Common polymers used include natural ones like collagen and alginate as well as synthetic biodegradable polymers like PLGA. Applications include ocular inserts and transdermal patches that use polymers to regulate drug diffusion out of a matrix over time.