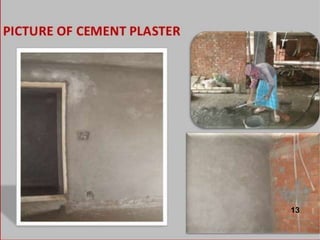

Plastering is a technique used to create protective and aesthetic finishes on surfaces, aiming for a smooth, durable result while protecting against environmental factors. Various types of plaster, such as lime, cement, and gypsum plaster, have distinct properties and applications, including specific mixing ratios and layering processes. Proper surface preparation and application techniques are essential to prevent issues like cracking and unevenness.